Food Production Line Equipment - Chinese Manufacturer, Factory, Supplier

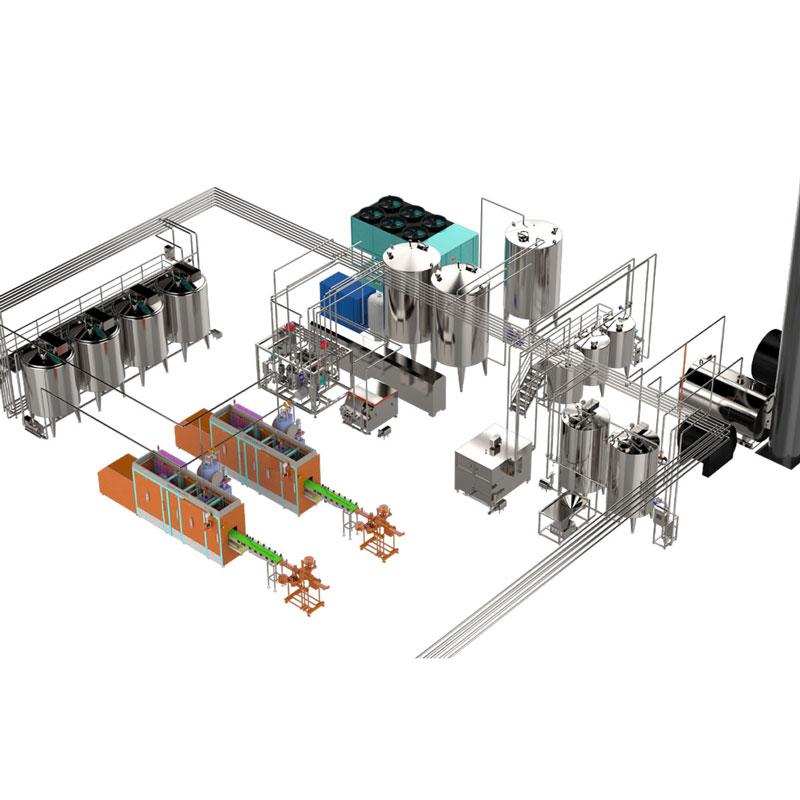

Modern Food Production Line Equipment plays a vital role in shaping the efficiency, consistency, and scalability of today’s food manufacturing operations. Designed to handle a wide spectrum of processes — from raw material preparation through to final packaging — this equipment is the backbone of industrial food production across numerous sectors, including bakery, meat processing, dairy, snacks, and beverages.

Advanced Food Production Line Equipment integrates automation, precision engineering, and intelligent control systems to ensure seamless workflows and reduced labor dependency. Whether it’s mixing, slicing, cooking, cooling, or packaging, each machine is engineered for maximum output with minimal waste. These systems help manufacturers achieve strict quality standards while optimizing production speed, energy consumption, and operational costs.

One of the defining advantages of modern Food Production Line Equipment is its flexibility. Modular designs allow manufacturers to scale production capacity or adapt to new product types with relative ease. From small-scale facilities looking to automate specific processes to large corporations aiming for fully integrated turnkey solutions, this equipment offers customizable options to meet diverse operational requirements.

Hygiene and food safety are paramount considerations in the design of Food Production Line Equipment. Stainless steel construction, seamless welding, and easy-to-clean components ensure compliance with international standards, including HACCP, ISO, and CE certifications. These features not only protect end consumers but also extend equipment lifespan and reduce downtime.

Investing in high-quality Food Production Line Equipment empowers businesses to stay competitive in a rapidly evolving market. It enables faster time-to-market, consistent product quality, and enhanced operational control — all crucial factors for success in the global food industry.

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Yogurt Production Line

Yogurt Production Line Cake Production Line

Cake Production Line Sausage Processing Line

Sausage Processing Line Double-Door Steaming Cabinet with Viewing Window

Double-Door Steaming Cabinet with Viewing Window Gizzard Peeling Machine

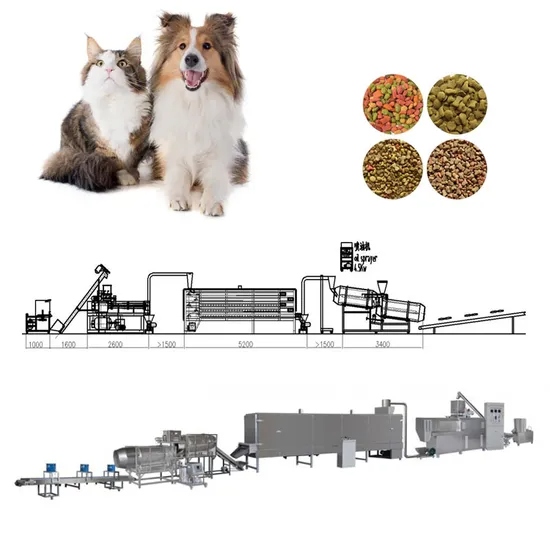

Gizzard Peeling Machine Dry Pet Food Production Line

Dry Pet Food Production Line Cutting And Stringing Integrated Machine

Cutting And Stringing Integrated Machine Sausage Automatic Double Wire Binding Machine

Sausage Automatic Double Wire Binding Machine