Commercial Chicken Meat Cutting Dicer Machine - Chinese Manufacturer, Factory, Supplier

A commercial chicken meat cutting dicer machine is an indispensable tool for butcher shops, poultry processing plants, restaurants, and ready-to-cook food manufacturers. Designed specifically for chicken and other poultry products, this machine automates the process of cutting whole chicken pieces into uniform dice, ensuring consistency, efficiency, and food safety across production lines.

The primary advantage of a chicken meat cutting dicer machine lies in its ability to produce perfectly sized cubes rapidly and uniformly. Whether preparing chicken for soups, stir-fries, frozen meals, or marinated dishes, consistent dicing is crucial for presentation, cooking uniformity, and portion control. With adjustable blade grids and variable cutting speeds, operators can achieve precise dice sizes according to specific recipes or product requirements.

Durability and hygiene are central to the design of these machines. Built from heavy-duty, food-grade stainless steel, commercial chicken meat dicing machines resist corrosion and are easy to sanitize. Detachable components, smooth surfaces, and compliance with HACCP, GMP, and ISO standards minimize contamination risks. Safety features, such as protective guards, emergency stop buttons, and interlocks, ensure operator protection during high-speed processing.

Efficiency is another major benefit. By automating the dicing process, businesses can drastically reduce labor costs, improve throughput, and maintain uniform product quality. Large-capacity hoppers and continuous feed systems enable the machine to handle hundreds or even thousands of kilograms of chicken per hour, making it suitable for both small-scale commercial kitchens and industrial poultry processing facilities.

Modern chicken meat dicer machines often come with programmable controls, allowing operators to adjust dice size, feed speed, and cutting cycles for different product types. Advanced units can integrate seamlessly with upstream and downstream equipment such as chicken deboning machines, meat mixers, marinating lines, or packaging systems, creating a fully automated production line.

Different models are available to suit various business scales. Compact semi-automatic units are ideal for restaurants and small butcher shops, while fully automatic industrial machines serve high-volume poultry processing plants. Leading manufacturers typically provide installation support, operator training, spare parts, and technical assistance to ensure smooth and reliable operation.

Investing in a commercial chicken meat cutting dicer machine enhances productivity, reduces labor, and guarantees consistent product quality. By combining precision, speed, and hygiene, this equipment is essential for any modern poultry processing operation, allowing businesses to meet increasing consumer demand while maintaining high standards in food preparation and safety.

| Feature / Machine Type | Chicken Meat Dicer Machine | Meat Dicing Machine | Meat Cutter Machine |

|---|---|---|---|

| Primary Function | Dice chicken or poultry into uniform cubes | Dice various meats into cubes | Slice, dice, or portion meat |

| Typical Output | Chicken cubes for soups, stir-fries, frozen meals | Cubes for soups, stews, ready meals | Steaks, diced meat, shredded meat, deli slices |

| Capacity | Medium to high (100–1,500+ kg/h) | Medium to high (100–1,000+ kg/h) | Small to industrial (50–2,000+ kg/h) |

| Blade / Cutting Type | Grid or multi-blade stainless steel | Grid or multi-blade stainless steel | Straight, dicing, or adjustable blades |

| Adjustable Sizes | Yes, small/medium/large cubes | Yes, small/medium/large cubes | Yes, slice thickness or dice size |

| Automation Level | Semi-automatic to fully automatic | Semi-automatic to fully automatic | Manual to fully automatic |

| Hygiene & Safety | Food-grade stainless steel, HACCP/GMP/ISO compliant, protective guards | Food-grade stainless steel, HACCP/GMP/ISO compliant, protective guards | Food-grade stainless steel, HACCP/GMP/ISO compliant, protective guards |

| Best For | Poultry processing plants, restaurants, catering, frozen food factories | Restaurants, catering, frozen food factories, industrial kitchens | Butcher shops, restaurants, industrial meat processing |

| Key Advantage | Precision chicken dicing, high speed, reduces labor | Uniform meat cubes, versatile for various meat types | Versatile cutting options, scalable for industrial use |

| Price Range | $5,000 – $25,000+ | $3,000 – $20,000+ | $1,500 – $80,000+ |

Chicken Soup Canned Production Line

Chicken Soup Canned Production Line French Fries Cutting Machine

French Fries Cutting Machine Automatic Chicken Canned Food Production Line

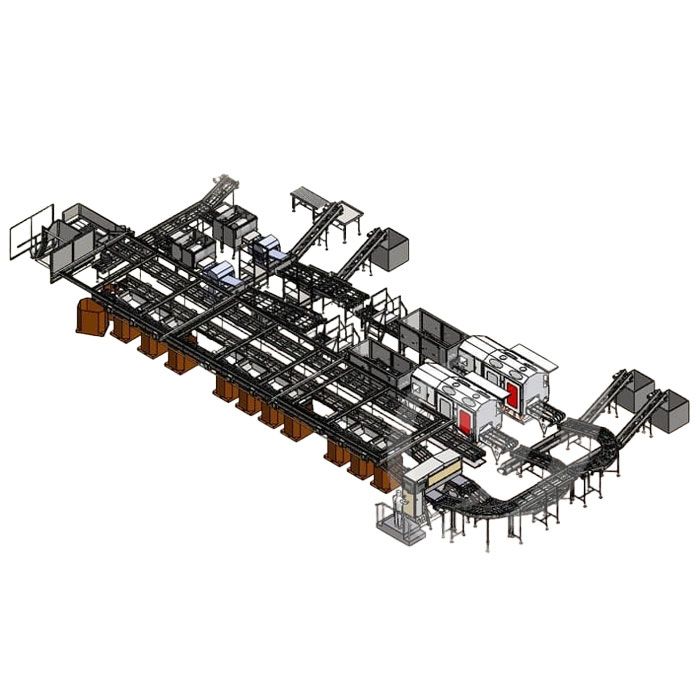

Automatic Chicken Canned Food Production Line Chicken Production Line

Chicken Production Line Meat Dicers

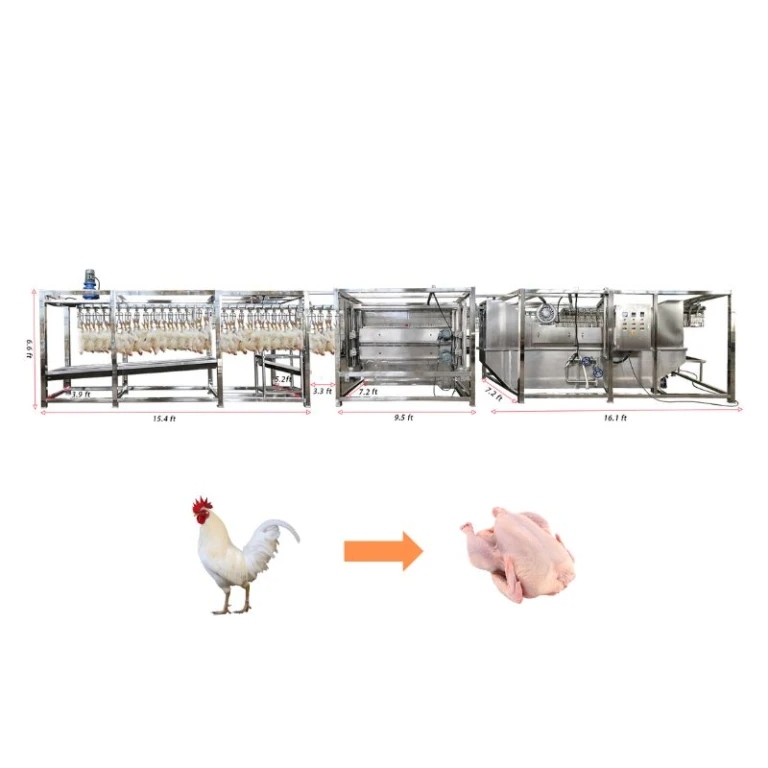

Meat Dicers Chicken Slaughtering Machine

Chicken Slaughtering Machine Chicken Plucker Machine

Chicken Plucker Machine Chicken Egg Peeling Machine

Chicken Egg Peeling Machine Fish Cutting Machine

Fish Cutting Machine Chicken Feet Peeling Production Line

Chicken Feet Peeling Production Line Small Chicken Feet PeelingMachine

Small Chicken Feet PeelingMachine Big Chicken Feet Peeling Machine

Big Chicken Feet Peeling Machine Fully Automatic Canned Tuna Processing Production Line

Fully Automatic Canned Tuna Processing Production Line Standard Integrated Weighing and Packaging Machine

Standard Integrated Weighing and Packaging Machine Braised Pork Belly Can Production Line

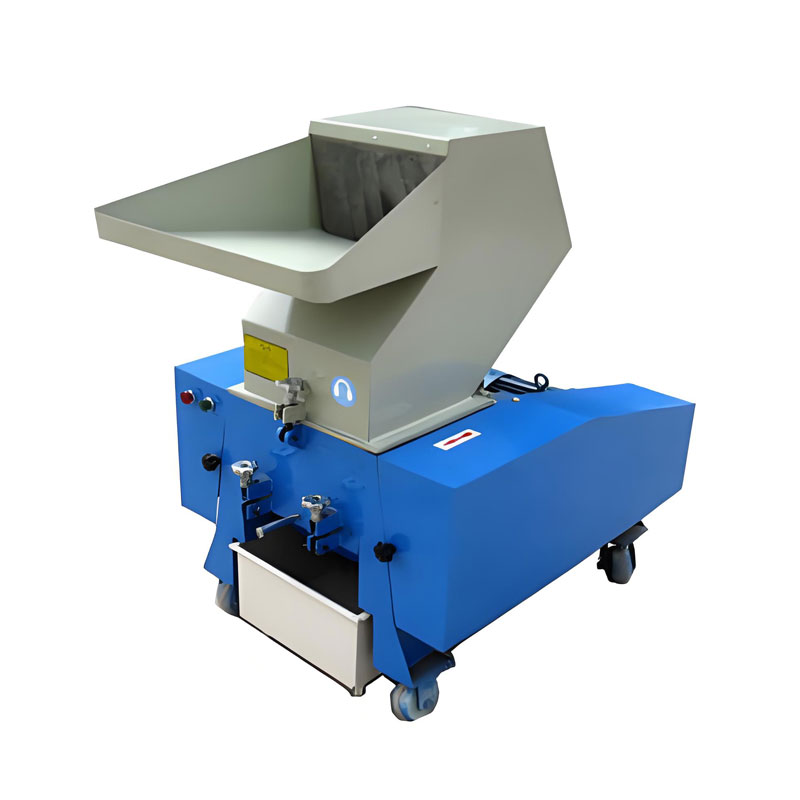

Braised Pork Belly Can Production Line Automatic Bone Crushing Machine

Automatic Bone Crushing Machine Tomato Ketchup Processing Line

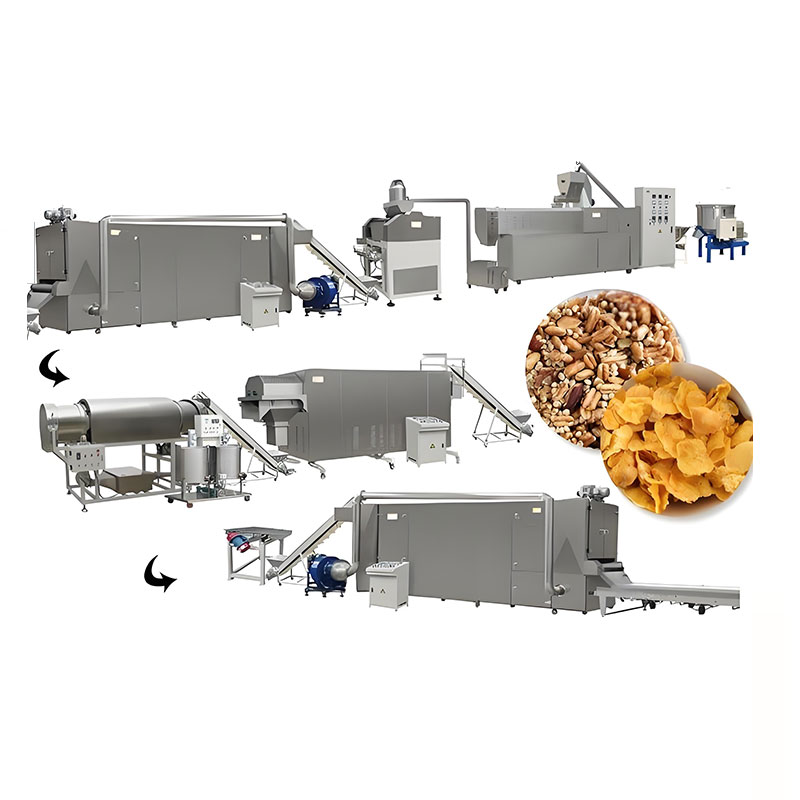

Tomato Ketchup Processing Line Corn Flakes Food Production Line

Corn Flakes Food Production Line Automatic Rice Production Line

Automatic Rice Production Line