🥦 Introduction

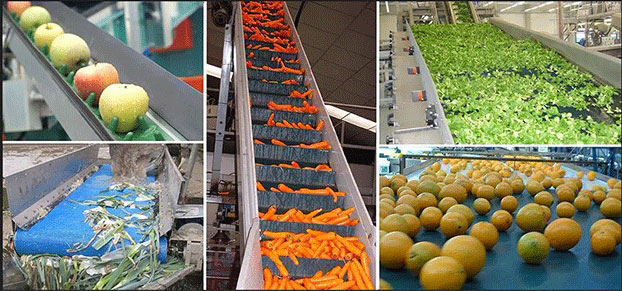

The vegetable canning production line is a fully automated system designed for cleaning, cutting, blanching, filling, sterilizing, and packaging a wide variety of vegetables, such as green beans, corn, peas, carrots, mushrooms, and mixed vegetables. It ensures consistent quality, long shelf life, and compliance with international food safety standards (HACCP, ISO22000, FDA, GMP).

Vegetable canning plays a crucial role in stabilizing supply chains, reducing food waste, and extending product availability beyond harvest seasons.

⚙️ 1. Main Processing Flow

Raw Material Preparation 🥬

Sorting, grading, and washing fresh vegetables.

Removing impurities, stones, and damaged pieces.

Cutting and Blanching 🔪🔥

Cutting into required sizes.

Blanching to inactivate enzymes, preserve color, and enhance texture.

Filling and Brine Addition 🥫

Automatic filling of vegetables into cans, jars, or pouches.

Addition of brine, syrup, or seasoning liquid.

Seaming and Sterilization 🛡

Hermetic sealing with can seamers.

High-temperature sterilization (retort/autoclave) ensures long shelf life.

Cooling and Labeling ❄️🏷

Gradual cooling prevents texture damage.

Automatic labeling and coding for traceability.

Packaging and Palletizing 📦

Secondary packing for logistics.

Automated palletizing for bulk storage and transport.

🚀 2. Key Features & Advantages

Modular Design: Flexible line configuration for different vegetable types.

Automation: PLC touch-screen control for efficiency and consistency.

Food Safety: Stainless steel (SS304/316) ensures hygiene and durability.

High Efficiency: Continuous processing reduces manual handling.

Versatility: Suitable for canned, glass jar, and retort pouch packaging.

Energy Saving: Optimized blanching and sterilization systems reduce energy consumption.

📊 3. Technical Specifications (Typical Line Setup)

| Section | Capacity | Power | Material | Notes |

|---|---|---|---|---|

| Washing & Sorting Machine | 500–2000 kg/h | 3–7.5 kW | SS304 | Bubble washer + conveyor |

| Cutting Machine | 300–1500 kg/h | 2–5.5 kW | SS304 | Adjustable size |

| Blanching Machine | 500–2000 kg/h | 10–30 kW | SS304 | Steam or hot water |

| Filling Machine | 30–100 cans/min | 2–5 kW | SS304 | Weighing/volumetric |

| Can Seamer | 30–80 cans/min | 2–4 kW | SS304 | Double seaming |

| Retort Sterilizer | 500–2000 kg/batch | 15–45 kW | SS316 | Steam/water spray |

| Cooling Tunnel | 500–2000 kg/h | 5–10 kW | SS304 | Continuous cooling |

| Labeling & Packaging | 20–60 packs/min | 3–5 kW | SS304 | Label + carton |

🌍 4. Applications

Canned beans, peas, corn, carrots, mushrooms

Mixed vegetable cans or pouches

Pickled vegetable jars

Export-oriented vegetable processing plants

💰 5. Efficiency & ROI

Labor Savings: Up to 60% less manual work.

Quality Consistency: Ensures uniform size, taste, and texture.

Food Safety: Meets domestic and international compliance.

Fast ROI: Investment payback typically within 1–2 years due to high-volume output and reduced waste.

🔮 6. Future Trends

Plant-based diets growth 🌿: Rising demand for healthy canned vegetables.

Smart Manufacturing 🤖: IoT-enabled monitoring and predictive maintenance.

Sustainable Production 🌍: Energy-efficient sterilization and eco-friendly packaging.

✅ Conclusion

The vegetable canning production line provides a complete, hygienic, and efficient solution for producing high-quality canned vegetables at industrial scale. With modular configurations, compliance with international standards, and options for customization, it helps manufacturers expand capacity, improve safety, and maximize profitability.

Must-read blogs for bosses