Meat Processing Machinery - Chinese Manufacturer, Factory, Supplier

Meat processing machinery plays a central role in modern food manufacturing, offering efficient, hygienic, and scalable solutions for transforming raw meat into high-quality consumer products. From basic cutting and mincing operations to advanced deboning, mixing, forming, and packaging, these machines are designed to streamline production while meeting rigorous international food safety standards.

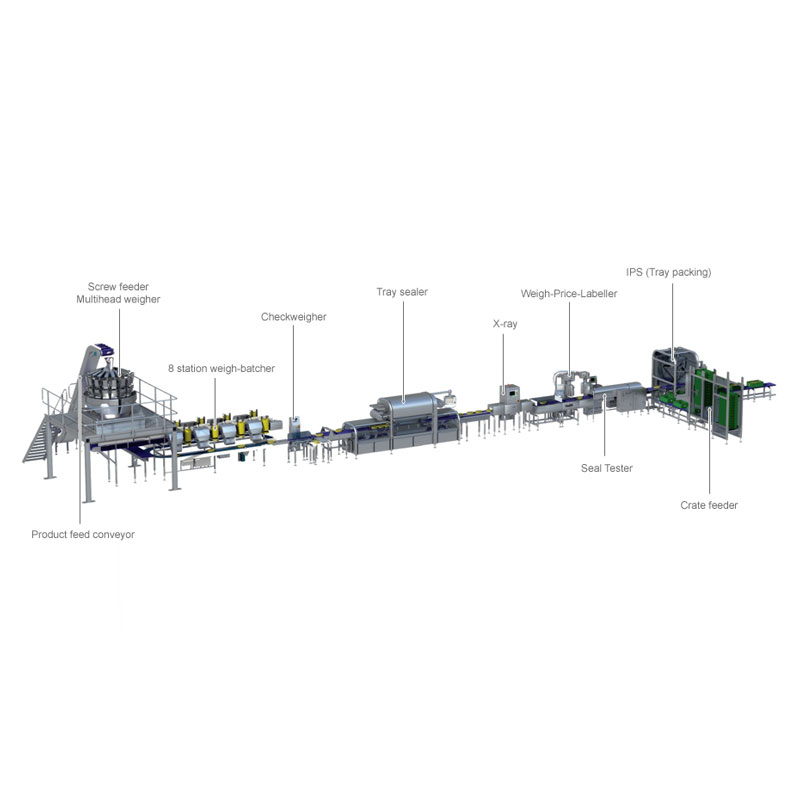

The process begins with cutting and portioning equipment, which ensures precise sizing for beef, pork, poultry, or lamb. Automated cutting machines improve yield, reduce waste, and provide uniformity that is essential for downstream operations. Meat grinders and mincers handle both fine and coarse textures, preparing raw material for sausages, patties, dumplings, and other value-added products.

For processing plants requiring high throughput, deboning and slicing machinery eliminates labor-intensive manual work. These machines are engineered with advanced blades and sensors to separate bone from meat with accuracy, maximizing recovery rates. Next, mixing and tumbling equipment blends meat with spices, brines, or marinades, ensuring consistent flavor distribution and product uniformity.

In the shaping and forming stage, patty makers, sausage fillers, and meatball formers enable rapid production of standardized portions, ideal for both retail and foodservice packaging. To maintain quality and extend shelf life, vacuum tumblers, injectors, and tenderizers enhance texture, juiciness, and preservation.

A critical aspect of meat processing is food safety. Sterilization and hygiene systems are integrated into machinery design, featuring stainless steel construction, easy-clean surfaces, and CIP (clean-in-place) functions to meet HACCP and ISO requirements. Additionally, metal detectors and inspection equipment safeguard against contamination, ensuring end products comply with export regulations.

Final stages involve packing and sealing machines, ranging from vacuum packaging to modified atmosphere packaging (MAP). These technologies lock in freshness, preserve flavor, and extend shelf life during distribution. High-speed cartoning and palletizing systems then prepare finished goods for efficient logistics.

By investing in meat processing machinery, manufacturers benefit from increased productivity, reduced labor dependency, improved product consistency, and compliance with global food safety standards. Customizable configurations allow production lines to adapt to specific product categories, whether canned meat, frozen cuts, ready-to-eat meals, or specialty delicacies.

In today’s competitive market, advanced meat processing machinery is not merely an operational necessity but also a strategic asset, enabling food producers to achieve cost efficiency, maintain brand reputation, and meet growing consumer demand worldwide.

Heavy Duty Commercial Meat Grinder

Heavy Duty Commercial Meat Grinder Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Full-automatic Meat Smoke Oven

Full-automatic Meat Smoke Oven Cookie Production Line

Cookie Production Line Fully Automatic Canned Tuna Processing Production Line

Fully Automatic Canned Tuna Processing Production Line Poultry Line

Poultry Line Fruit And Vegetable Canned Production Line

Fruit And Vegetable Canned Production Line Potato Processing Line

Potato Processing Line Dual-Roll Steamed Bun Machine

Dual-Roll Steamed Bun Machine SF Series Snowflake Ice Machine

SF Series Snowflake Ice Machine Biscuit Line

Biscuit Line