Mackerel Canned Food Production Line - Chinese Manufacturer, Factory, Supplier

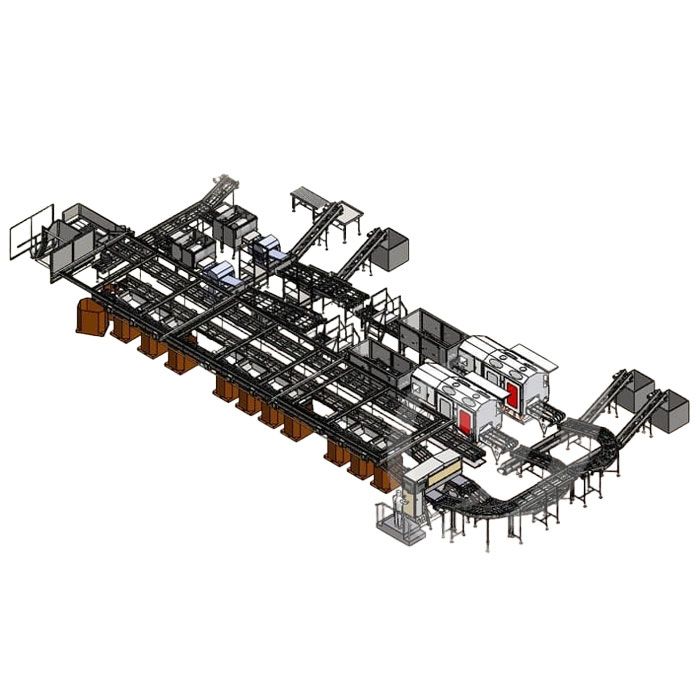

The modern Mackerel Canned Food Production Line represents a seamless integration of technology, hygiene, and productivity. It transforms raw mackerel into shelf-stable, market-ready products through a highly controlled, automated workflow designed to meet the rigorous standards of today’s food industry.

Initial processing begins with automated feeding systems that ensure gentle handling of the fish, minimizing damage and maintaining freshness. Specialized pre-cooking units, often using steam or hot water methods, are applied to enhance flavor retention and facilitate bone softening. Following this, automated de-heading, gutting, and portioning systems prepare uniform cuts, reducing manual intervention and increasing throughput.

The core of the Mackerel Canned Food Production Line lies in its precision filling and sealing modules. These systems are engineered to handle diverse recipes—such as oil-packed, spicy, or seasoned variants—while maintaining exact dosing accuracy. High-speed seaming machines provide airtight closures that protect the product during sterilization and storage, ensuring long-term safety and quality.

Sterilization chambers, utilizing retort technology, subject the sealed cans to precise thermal treatment, eradicating microorganisms without compromising texture or flavor. Inline quality control systems, including real-time sensor checks and automated rejection mechanisms, uphold stringent quality benchmarks at every stage.

With customizable layouts and modular components, the Mackerel Canned Food Production Line adapts to production capacities ranging from small-scale facilities to fully industrial operations. Energy-efficient designs, waste-reduction mechanisms, and user-friendly interfaces contribute to sustainable and cost-effective processing.

By adopting an advanced Mackerel Canned Food Production Line, seafood processors gain a competitive advantage—delivering consistent, safe, and premium canned mackerel to an ever-expanding global market.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Fruit And Vegetable Canned Production Line

Fruit And Vegetable Canned Production Line Automatic Twisting Quantitative Sausage Stuffer Machine

Automatic Twisting Quantitative Sausage Stuffer Machine Double-Door Steaming Cabinet with Viewing Window

Double-Door Steaming Cabinet with Viewing Window Braised Pork Belly Can Production Line

Braised Pork Belly Can Production Line Big Chicken Feet Peeling Machine

Big Chicken Feet Peeling Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Cuber Machine

Meat Cuber Machine Small Chicken Feet PeelingMachine

Small Chicken Feet PeelingMachine Dual-Roll Steamed Bun Machine

Dual-Roll Steamed Bun Machine