Meat Slicer For Cutting Steaks - Chinese Manufacturer, Factory, Supplier

As a professional manufacturer, supplier, and wholesaler of meat cutting equipment, we are committed to providing superior steak slicers. We take pride in our factory located in Yuanlin, offering exceptional customization services to meet your unique needs.

We approach every aspect of our business - from manufacturing and supply to customization and procurement - with utmost professionalism. Our equipment is carefully designed, incorporating advanced technology and expert craftsmanship to ensure precision and efficiency in steak cutting.

At our Yuanlin facility, we prioritize the quality of each meat slicer, offering a diverse range of options to cater to varying market demands. We not only sell top-tier equipment but also provide flexible customization options to help your business stand out in a competitive market.

In the sales process of our meat slicers, we guarantee excellent after-sales service, ensuring your equipment maintains optimal performance. Choosing us means selecting a professional and reliable partner, providing ideal solutions for all your meat cutting requirements.

Frozen Meat Slicer

Frozen Meat Slicer Meat Dicing Machine

Meat Dicing Machine Vacuum Stuffing Machine

Vacuum Stuffing Machine Vacuum Quantitative Filling Machine

Vacuum Quantitative Filling Machine Frozen Meat Grinder

Frozen Meat Grinder Cutting And Stringing Integrated Machine

Cutting And Stringing Integrated Machine Stuffed Meatball Machine

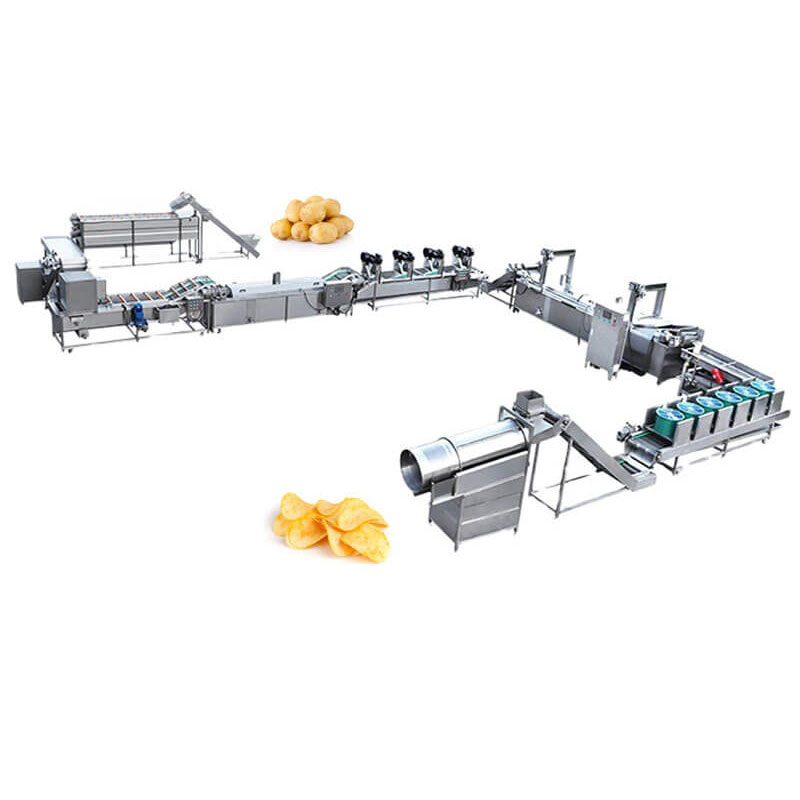

Stuffed Meatball Machine Crisp Production Line

Crisp Production Line Hydraulic Sausage Filling Machine

Hydraulic Sausage Filling Machine Fish Deboner Machine

Fish Deboner Machine YL-W-02 Commercial Water Purification Equipment

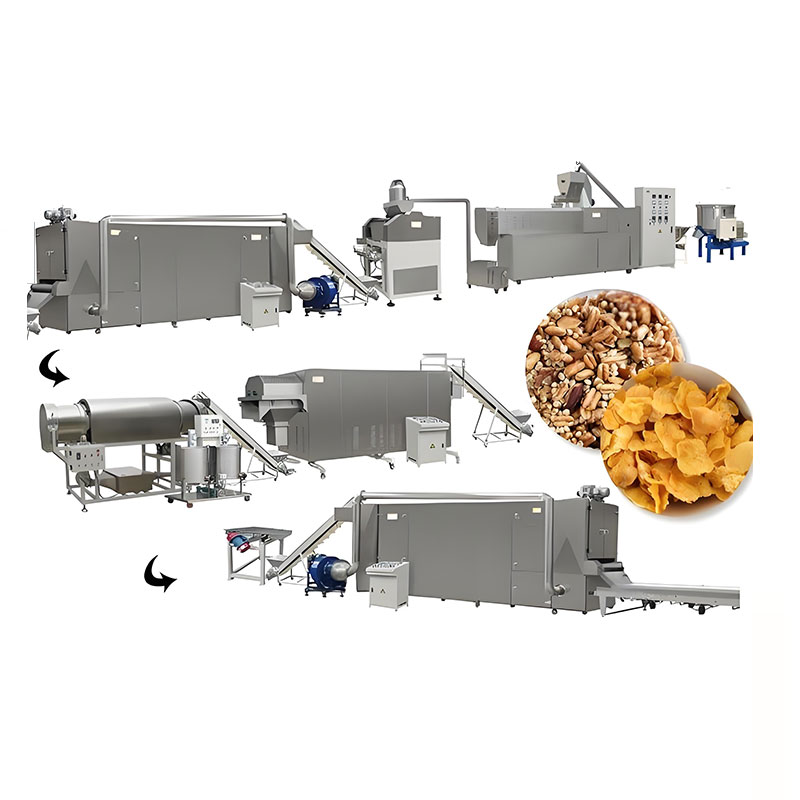

YL-W-02 Commercial Water Purification Equipment Corn Flakes Food Production Line

Corn Flakes Food Production Line Egg Canning Production Line

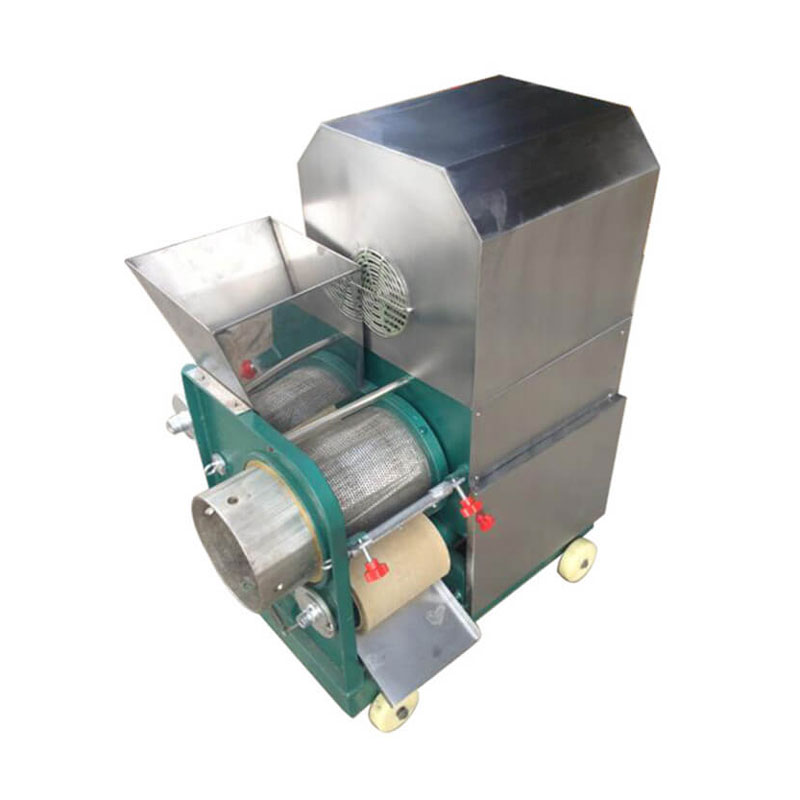

Egg Canning Production Line Bowl Cutter

Bowl Cutter