Pasta Cooking Equipment Manufacturer - Chinese Manufacturer, Factory, Supplier

An experienced Pasta Cooking Equipment Manufacturer understands that large-scale pasta preparation is as much about process control as it is about heat and water. In busy production kitchens, catering facilities, and industrial pasta plants, every second counts. Equipment must not only cook pasta to the precise al dente point, but also handle high volumes without sacrificing texture or consistency.

Our approach as a specialized Pasta Cooking Equipment Manufacturer begins with engineering cookers that manage heat transfer and water flow with exacting precision. Uniform circulation systems prevent clumping, while rapid recovery heating elements keep production moving even during peak demand. This means consistent results from the first batch to the last, day after day.

Built from polished food-grade stainless steel, each unit is designed for demanding environments where hygiene and speed matter equally. Sloped tank bottoms, smooth welds, and tool-free drainage systems allow for fast cleaning between runs, minimizing downtime and safeguarding food safety.

Modern designs from a top-tier Pasta Cooking Equipment Manufacturer also integrate automation that matters—programmable cooking profiles for different pasta types, automated water replenishment to maintain optimal starch balance, and smart sensors that adjust temperature in real time. The result is less manual oversight, reduced labor strain, and higher output without compromising quality.

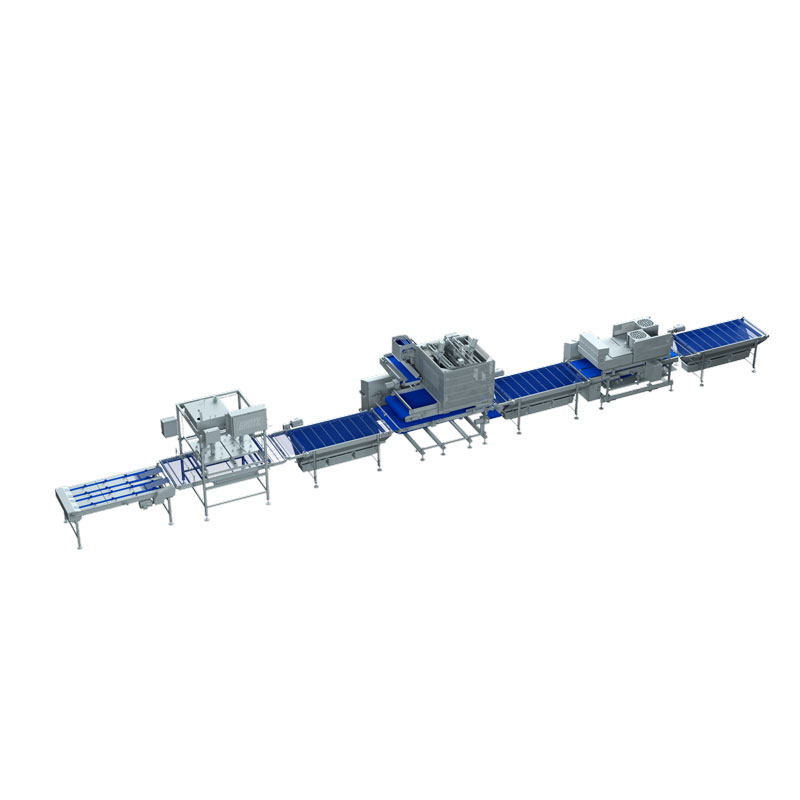

Customization is key. Whether producing short pasta for ready-meal packaging or long strands for fresh retail sale, a dedicated Pasta Cooking Equipment Manufacturer can tailor machine capacity, basket configuration, and integration with cooling or packaging lines to fit your exact workflow.

The value of choosing the right manufacturing partner extends beyond the machine itself. From installation and operator training to preventive maintenance programs, the goal is to ensure your cooking line runs with maximum uptime and efficiency, even under continuous operation.

For producers aiming to scale, streamline, and maintain a premium product standard, a trusted Pasta Cooking Equipment Manufacturer offers more than hardware—it delivers the means to transform pasta cooking from a manual process into a high-output, precision-controlled operation.

Commercial Dry Pasta Machine

Commercial Dry Pasta Machine Commercial Pasta Extruder

Commercial Pasta Extruder Commercial Pasta Sheeter

Commercial Pasta Sheeter Pasta Machine

Pasta Machine Multifunction Pasta Machine

Multifunction Pasta Machine YL-W-04 Commercial Water Purification Equipment

YL-W-04 Commercial Water Purification Equipment Automatic Meat Mixer Machine

Automatic Meat Mixer Machine Fully Automated Pizza Production Line

Fully Automated Pizza Production Line Fish Food Processing Line

Fish Food Processing Line Small Scale Banana Chips Production Line

Small Scale Banana Chips Production Line Dual-Roll Steamed Bun Machine

Dual-Roll Steamed Bun Machine Full-automatic Meat Smoke Oven

Full-automatic Meat Smoke Oven Cake Production Line

Cake Production Line