🔍 Overview

The demand for ready-made pizzas—frozen, chilled, or par-baked—has surged worldwide. To meet this growing market, a fully automated pizza production line provides food manufacturers with scalable, hygienic, and high-speed solutions that ensure consistency in quality and output. Our turnkey pizza lines support custom sizes, shapes, and toppings with full automation from dough mixing to final packaging.

⚙️ Processing Flow Diagram

Here is a typical process for a frozen or chilled pizza production line:

[ Dough Mixing & Resting ] ↓ [ Dough Sheet Forming ] ↓ [ Dough Proofing Tunnel (Optional) ] ↓ [ Pre-Baking Oven ] ↓ [ Sauce Dispensing ] ↓ [ Topping (Cheese, Meat, Veggies) Application ] ↓ [ Final Baking / Melting Tunnel (Optional) ] ↓ [ Freezing / Chilling Tunnel ] ↓ [ Slicing (Optional) & Metal Detection ] ↓ [ Packaging & Labeling ] ↓ [ Carton Packing & Palletizing ]

🧩 Key Components of the Pizza Production Line

1. Dough Handling System

Spiral mixer or continuous mixer with variable speed

Resting conveyor or chamber to relax dough

Optional: oil sprayer for dough surface

2. Dough Forming & Shaping

Rotary cutter for round, square, or custom shapes

Roller sheeter with thickness adjustment (2–15 mm)

Scrap return system to minimize waste

3. Proofing Tunnel (Optional)

For fresh dough products

Temperature: 30–40°C | Humidity: 70–85%

Stainless steel modular conveyors inside

4. Pre-Baking Oven

Stone plate oven or tunnel oven

Heating: electric, gas, or hybrid

Speed and temperature programmable

Bake temperature: 220–300°C

5. Sauce & Toppings Station

Spiral sauce applicator or rotary spreader

Automatic topping dispensers for:

Cheese (shredded, sliced)

Pepperoni, sausage, bacon

Bell peppers, onions, mushrooms, olives

Weighing control to ensure topping accuracy

6. Final Baking / Melting Tunnel

Optional depending on product type (fully baked vs. par-baked)

Infrared or convection heating

Melting and light browning for cheese

7. Cooling / Freezing Section

Spiral freezer (IQF) or tunnel freezer

Freezing temp: –18°C to –40°C

Capacity: up to 3000 pcs/hour

8. Cutting & Metal Detection (Optional)

Ultrasonic cutter for sliced pizzas

High-sensitivity metal detector integrated before packaging

9. Packaging & Palletizing

Flow packing, shrink wrapping, or MAP tray sealing

Date coder + automatic labeling

Robotic carton packing & palletizing arms

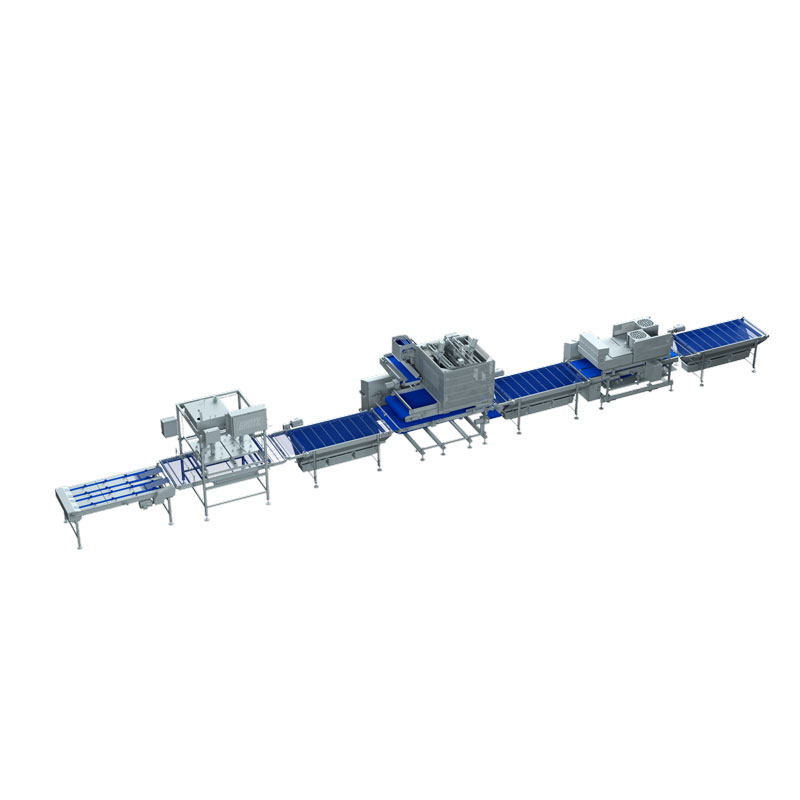

📐 Standard Layout Reference

A typical 20-meter × 6-meter layout (customizable for plant size):

[ Mixing Room ] ↓ [ Forming + Baking Zone ] ↓ [ Sauce + Topping Application ] ↓ [ Freezing Tunnel (U-shaped) ] ↓ [ Packaging Area ] ↓ [ Palletizing & Cold Storage ]

Note: Layout can be tailored to “I-type”, “U-type”, or “L-type” based on your plant’s shape.

📏 Technical Parameters (Sample Reference)

| Model | Output Capacity | Pizza Diameter | Oven Length | Freezer Type | Power (Total) |

|---|---|---|---|---|---|

| PZL-3000 | Up to 3000 pcs/h | 15–30 cm | 8–12 m | Spiral Freezer | 80–120 kW |

| PZL-1500 | Up to 1500 pcs/h | 10–25 cm | 6–10 m | Tunnel Freezer | 60–90 kW |

| PZL-500 | Up to 500 pcs/h | 8–20 cm | 4–6 m | Tunnel / Blast | 30–50 kW |

Note: Actual output depends on dough recipe, baking profile, and production mode.

🛠️ Customization Options

We provide end-to-end customization to match your business needs:

✅ Pizza Shape: Round, square, oval, heart-shaped, rectangular

✅ Size & Thickness: Mini-pizza (8 cm) to family-size (35 cm)

✅ Topping Modules: Multi-lane dispensers, weight-controlled systems

✅ Packaging Format: Tray sealing, flow wrap, shrink wrap, carton box

✅ Clean-in-Place (CIP): Available for sauce and topping systems

✅ Control Systems: Siemens/Omron PLC, HMI with remote diagnostics

✅ Certification: CE, UL, ISO, HACCP, FDA-compliant designs

🌍 Global Projects

We have delivered pizza production lines to:

🇩🇪 Germany: 2000 pcs/h frozen pizza line for supermarket supply

🇸🇦 Saudi Arabia: Halal-certified mini-pizza production for school meals

🇧🇷 Brazil: Chilled pizza line integrated with MAP packaging

🇮🇳 India: Vegetarian pizza line with energy-efficient electric ovens

📈 Business Benefits

| Benefit | Description |

|---|---|

| 💵 ROI | Typical payback within 12–18 months |

| 🔄 Efficiency | Reduce labor dependency by up to 60% |

| 🎯 Consistency | Uniform size, topping distribution & baking quality |

| 🧼 Hygiene | Stainless steel structure, food-grade belts, easy cleaning |

| 📦 Scalability | Expandable modules for increased output |

📦 What’s Included in Delivery

2D/3D layout plan + utility connection diagram

Full equipment list with documentation

PLC program + operation manuals

FAT (Factory Acceptance Test) video

On-site or remote installation training

Spare parts for 12 months

Global after-sales support

📞 Get Your Turnkey Pizza Line Project Proposal

Whether you're a startup or scaling up a large pizza factory, we’re here to help you design, install, and launch your pizza production line with confidence.

👉 Contact us now for a free consultation, CAD layout, and quotation.

Must-read blogs for bosses