Canned Fish Processing Machinery - Chinese Manufacturer, Factory, Supplier

Canned fish processing machinery is designed to provide efficient, hygienic, and high-quality solutions for seafood processing factories. These machines cover the entire production chain, including cleaning, cutting, cooking, filling, sealing, sterilizing, and packaging, enabling manufacturers to produce consistent and safe canned fish products for global markets.

Constructed with high-grade stainless steel, canned fish machinery ensures durability, corrosion resistance, and easy sanitation. Advanced systems allow precise control of processing parameters such as cooking temperature, filling volume, and sealing pressure, which ensures product uniformity, extends shelf life, and reduces waste.

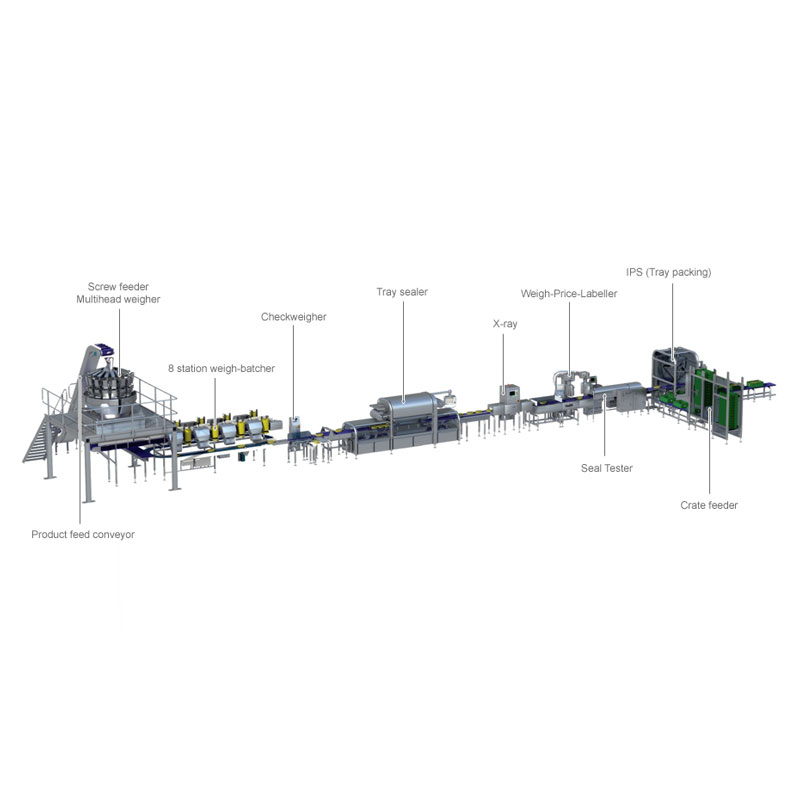

The machinery is versatile and capable of processing a wide variety of fish species, including sardines, mackerel, tuna, and salmon. Integrated production lines can include automatic washers, filleting machines, cutting machines, filling systems, can seamers, sterilizers, and packaging units, allowing for fully automated operation and high-volume output.

Applications include seafood canning factories, ready-to-eat meal producers, and export-oriented seafood processing plants. The equipment helps manufacturers achieve high efficiency, consistent quality, and compliance with international food safety standards such as HACCP, ISO 22000, and CE certification.

Qingdao Hongshengyuanlin Co., Ltd. provides complete canned fish processing solutions, including standalone machines and fully integrated turnkey lines. With extensive experience in exporting and integrating seafood processing systems worldwide, the company ensures each line is optimized for efficiency, hygiene, and long-term reliability. Services include factory layout design, equipment customization, installation supervision, operator training, and ongoing technical support, helping clients maximize productivity and maintain competitiveness in global markets.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Poultry Line

Poultry Line Chocolate Production Line

Chocolate Production Line Canned Food Filling And Sealing Line

Canned Food Filling And Sealing Line Small Chicken Feet PeelingMachine

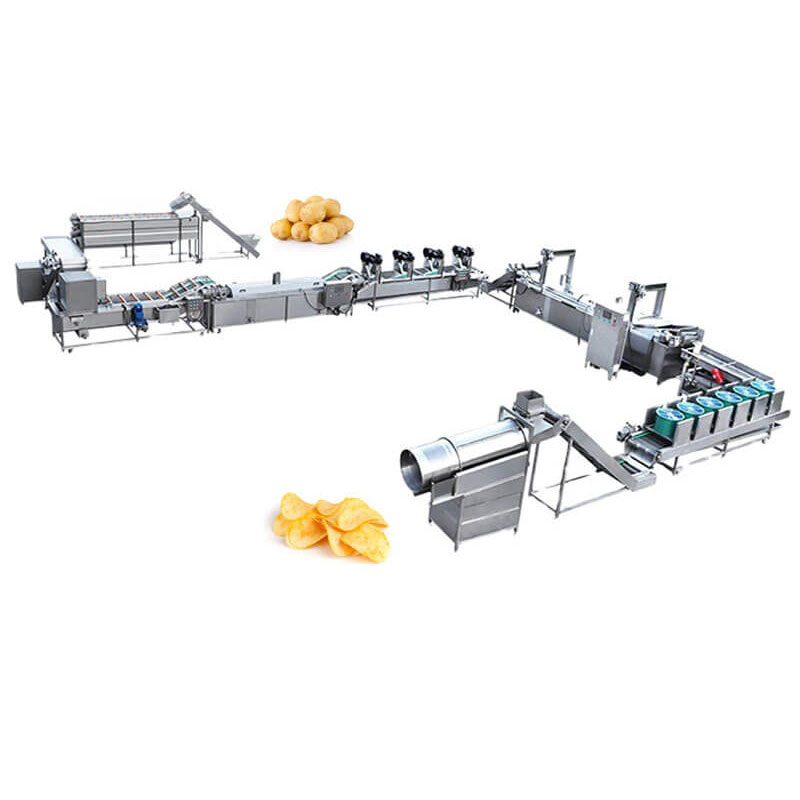

Small Chicken Feet PeelingMachine Screw Potato Peeling Washing Machine

Screw Potato Peeling Washing Machine Stuffed Meatball Machine

Stuffed Meatball Machine Crisp Production Line

Crisp Production Line Quantitative Vacuum Sausage Filler

Quantitative Vacuum Sausage Filler