Custom Shrimp Chips Production Line - Chinese Manufacturer, Factory, Supplier

In the expanding landscape of snack manufacturing, the Custom Shrimp Chips Production Line represents a specialized solution designed to meet rising global demand for seafood-based snacks. This intricate line integrates traditional Asian culinary principles with cutting-edge automation to create consistently high-quality shrimp chips with the desired puff, texture, and flavor.

A well-configured Custom Shrimp Chips Production Line typically includes mixing tanks, twin-screw extruders, slicing machines, drying tunnels, and frying systems. Each component is optimized to process raw ingredients—primarily tapioca starch, shrimp paste, and seasonings—into delicate, crispy chips that retain their taste and aroma long after packaging. The ability to precisely control temperature, moisture, and dwell time across each stage is critical to ensuring product uniformity.

Facilities like hongshengyuanlin factory have become industry leaders in this space by offering turnkey solutions that cater to a variety of market requirements. Known for their flexible engineering and technical expertise, hongshengyuanlin factory provides bespoke lines capable of producing shrimp chips in different shapes, sizes, and seasoning profiles. Their systems utilize stainless steel constructions, PLC control panels, and smart sensor integration to deliver efficiency, hygiene, and traceability—core pillars of modern food manufacturing.

The china Custom Shrimp Chips Production Line market continues to thrive, attracting global food processors seeking both customization and scalability. Chinese manufacturers are increasingly known for delivering fully automated production lines that meet international food safety standards while remaining cost-effective. From small-scale operators to multinational snack brands, the modular nature of these systems allows easy integration into existing facilities or greenfield projects.

A comprehensive Shrimp Chips Production Line Solution should go beyond hardware. It involves recipe development, equipment calibration, and post-sales technical support. The best systems offer adaptable configurations to accommodate new flavors, gluten-free variants, and even vegan alternatives—essential for brands aiming to capture health-conscious consumer segments.

Investing in a Custom Shrimp Chips Production Line is a strategic move for snack manufacturers aiming to diversify their portfolio while maintaining control over product quality and production costs. With advanced providers like hongshengyuanlin factory and robust offerings from the china Custom Shrimp Chips Production Line sector, businesses are well-equipped to capitalize on this growing niche in the global snack industry.

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Vegetable Dicing Machine

Vegetable Dicing Machine Smoked Furnace

Smoked Furnace Single Tank Single Basket Electric Fryer

Single Tank Single Basket Electric Fryer Canned Meat Production Line

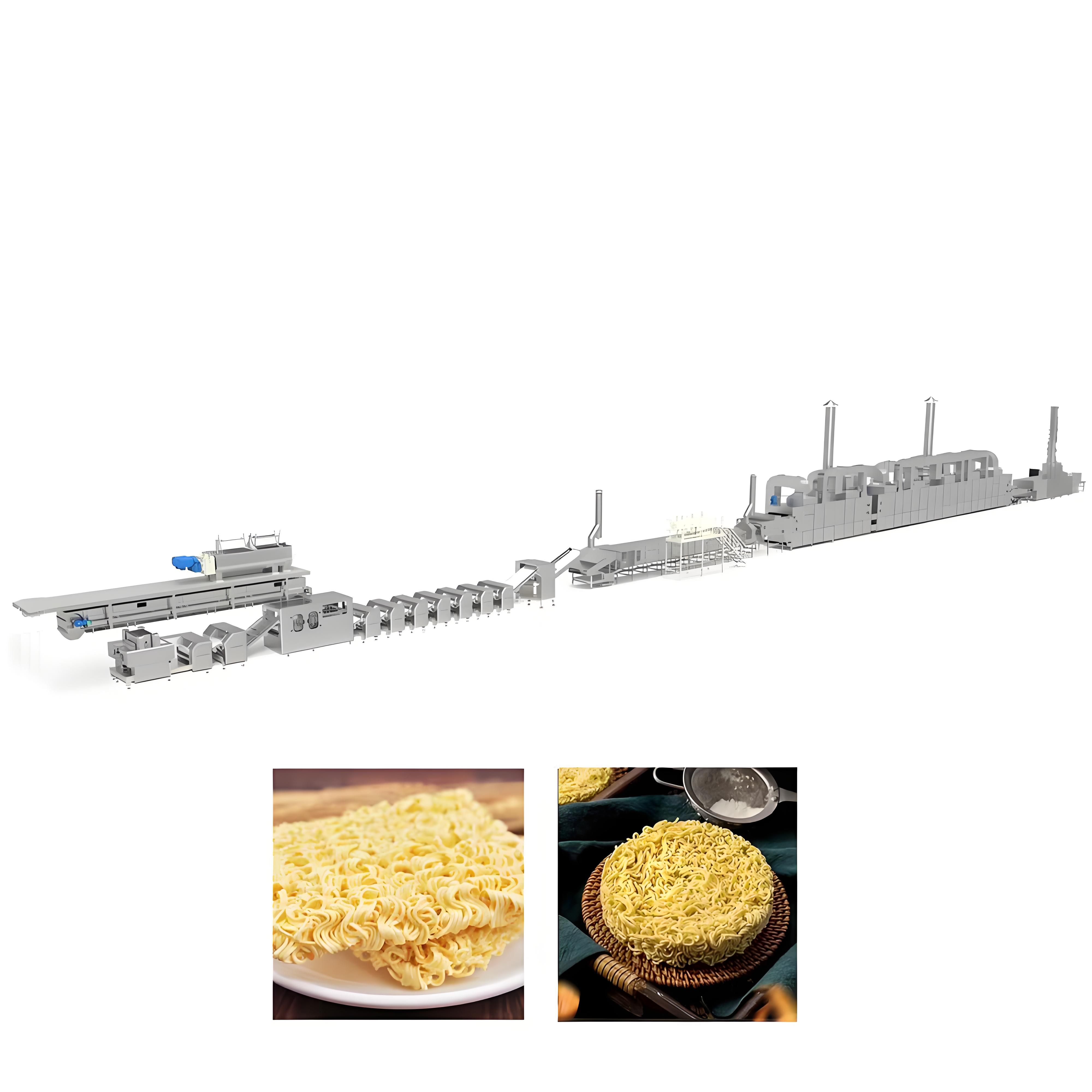

Canned Meat Production Line Deep-Fried Instant Noodle Production Line

Deep-Fried Instant Noodle Production Line SD-3000 / SD-4000 Commercial Cube Ice Maker

SD-3000 / SD-4000 Commercial Cube Ice Maker Sardine Canned Food Production Line

Sardine Canned Food Production Line Hydraulic Sausage Stuffer

Hydraulic Sausage Stuffer