Automatic Hot Sauce Filling Machine - Chinese Manufacturer, Factory, Supplier

An efficient and reliable filling machine is essential for businesses in the food industry, especially when it comes to packaging hot sauces. The Automatic Hot Sauce Filling Machine has revolutionized the way hot sauces are bottled, ensuring a streamlined process that guarantees speed, precision, and consistency. Whether you’re a small-scale producer or a large manufacturer, this equipment offers a host of benefits that make it an indispensable part of modern production lines.

One of the standout features of the Automatic Hot Sauce Filling Machine is its ability to handle various viscosities with ease. Hot sauces, ranging from thin, vinegary varieties to thicker, paste-like versions, can be filled with the same high level of efficiency. The machine uses advanced technology to accurately measure the sauce, filling bottles with perfect precision. This ensures that each container is filled to the same level, reducing wastage and maximizing production output.

Speed is another critical factor, and the Automatic Hot Sauce Filling Machine excels in this area. In today’s fast-paced market, speed is crucial for maintaining competitive advantage. These machines are designed to fill hundreds, if not thousands, of bottles per hour, depending on the model and setup. With automatic controls, the entire filling process becomes hands-free, significantly reducing the need for manual labor and minimizing the chances of human error. This efficiency directly translates to reduced production costs and faster turnaround times, which are vital for meeting market demand.

Moreover, the Automatic Hot Sauce Filling Machine is built with durability and reliability in mind. Constructed from high-quality stainless steel and designed to withstand the rigors of constant use, these machines are built to last. The material is not only robust but also hygienic, ensuring that the hot sauce remains uncontaminated throughout the filling process. For manufacturers focused on food safety and quality, this is a crucial factor.

The versatility of the Automatic Hot Sauce Filling Machine also deserves attention. These machines can handle various bottle types, from plastic containers to glass jars, and can be easily adjusted to suit different shapes and sizes. The flexibility to work with different packaging options allows producers to target a broader customer base and meet diverse market needs.

Maintenance of the Automatic Hot Sauce Filling Machine is also straightforward. With easy-to-clean components and automatic self-diagnosis systems, operators can quickly identify any issues and address them before they impact the production process. Regular maintenance ensures the machine continues to operate smoothly, extending its lifespan and keeping downtime to a minimum.

Another significant advantage of the Automatic Hot Sauce Filling Machine is its ability to integrate seamlessly into automated production lines. When paired with other machines, such as capping and labeling systems, the entire production process becomes synchronized and highly efficient. This integration leads to higher throughput and reduced manual labor, creating a smoother workflow that boosts overall productivity.

In conclusion, the Automatic Hot Sauce Filling Machine is an essential tool for hot sauce producers aiming for efficiency, precision, and scalability. With its ability to handle varying viscosities, impressive speed, and low maintenance requirements, this machine is a game-changer for the food packaging industry. Investing in such technology not only enhances production but also ensures that the final product meets the high standards of quality and consistency that customers expect.

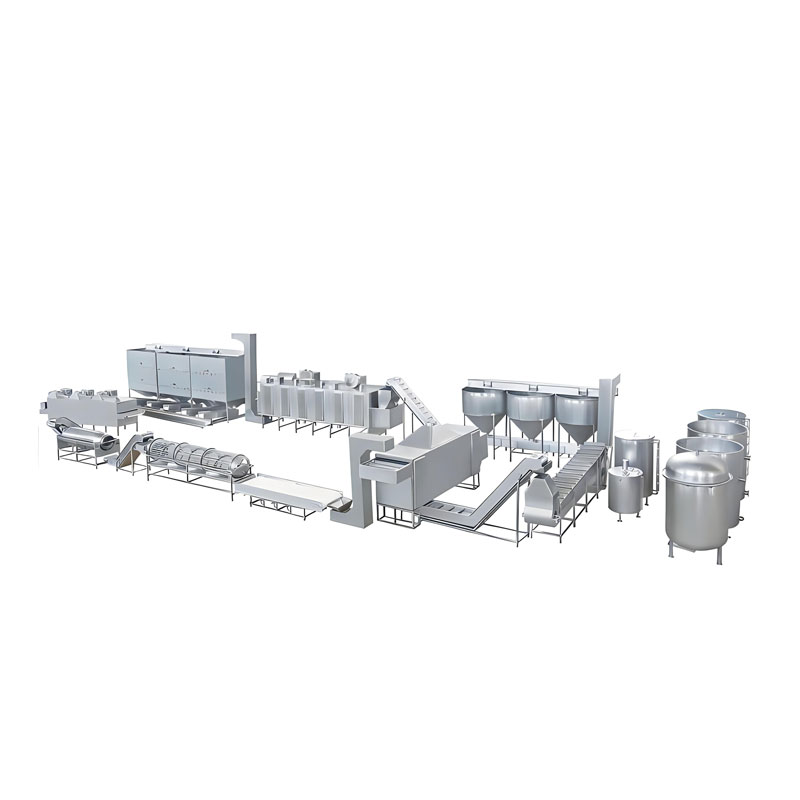

Small Scale Tomato Sauce Making Machine

Small Scale Tomato Sauce Making Machine Tomato Sauce Milling Machine

Tomato Sauce Milling Machine Tomato Sauce Grinding Machine

Tomato Sauce Grinding Machine Sauce Filling Machine

Sauce Filling Machine Tomato Sauce Machine

Tomato Sauce Machine Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine Meat Smoking Machine

Meat Smoking Machine Kimchi Production Line

Kimchi Production Line Meat Cuber Machine

Meat Cuber Machine Dairy Processing Lines

Dairy Processing Lines Double-Tank Vegetable Washing Machine

Double-Tank Vegetable Washing Machine Cooked Meat Shredder Machine

Cooked Meat Shredder Machine Potato Chips Instant Freezer

Potato Chips Instant Freezer Chicken Feet Cutting Machine

Chicken Feet Cutting Machine