🏭 Product Overview

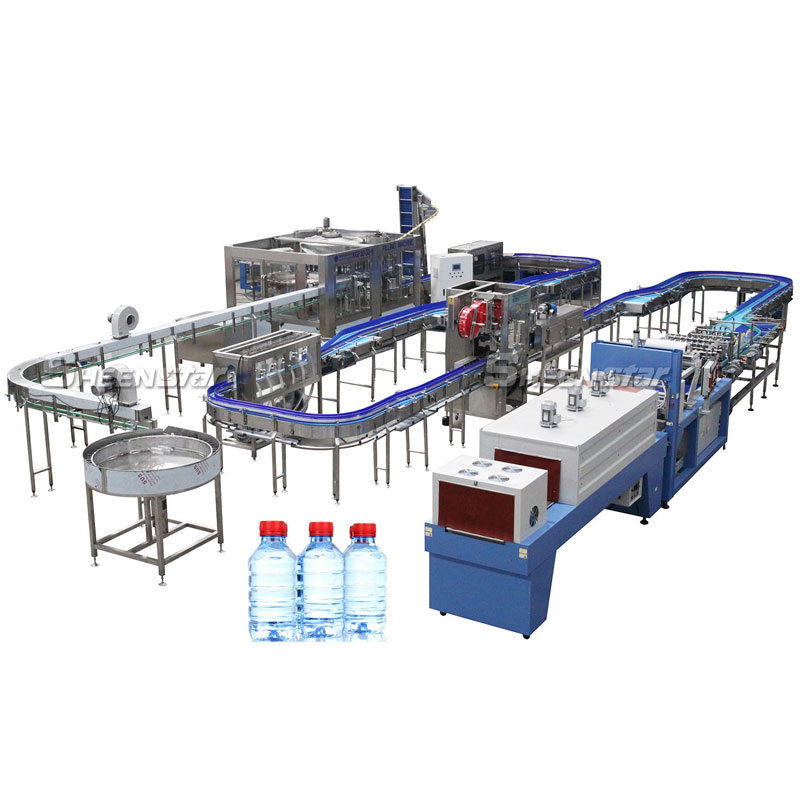

The Beverage Production Line is a fully integrated solution for manufacturing and packaging a wide range of liquid beverages — including fruit juice, tea drinks, carbonated soft drinks, mineral water, energy drinks, and flavored beverages.

Designed for commercial beverage factories and contract bottlers, this system combines precision engineering, hygiene standards, and automation technology to deliver high productivity, low operational cost, and consistent beverage quality.

The line covers the entire process from raw water treatment → syrup preparation → mixing → homogenizing → sterilizing → filling → capping → labeling → packaging, ensuring a smooth and contamination-free production cycle.

⚙️ Complete Production Process

1️⃣ Water Treatment System

Multi-stage purification system including sand filter, activated carbon filter, RO reverse osmosis membrane, and UV sterilization unit.

Guarantees that all process water meets food-grade standards, free from heavy metals and microorganisms.

Automatic backwash function and energy-saving pumps reduce maintenance costs.

2️⃣ Syrup Preparation & Mixing

High-precision mixing tanks with temperature control and variable-speed agitators for uniform sugar dissolving.

Optional inline blending system for continuous production without batch waiting.

Compatible with fruit concentrates, flavors, sweeteners, stabilizers, and vitamins.

3️⃣ Homogenization & Pasteurization

High-pressure homogenizers break down particles to ensure smooth texture and uniform taste.

Plate or tubular pasteurizers stabilize the product and extend shelf life.

Energy recovery design reduces steam consumption by up to 25%.

4️⃣ Filling & Sealing Section

Available in hot-fill, cold-fill, and carbonated versions.

Advanced CIP/SIP sterilization system ensures food safety and compliance with HACCP standards.

Suitable for PET bottles, glass bottles, aluminum cans, and tetra packs.

Filling valves adopt flow-meter control for high accuracy (±0.2%).

5️⃣ Capping & Labeling

Automatic cap sorting, feeding, and torque-adjustable tightening.

Labeling machines support shrink sleeve, adhesive paper, or OPP wrap-around labels.

Optional laser date printer and barcode system available.

6️⃣ Packaging & Palletizing

Shrink film wrapping or carton packing for retail and bulk packaging.

Integrated automatic palletizing system improves logistics efficiency.

Optional robotic arms for unmanned stacking and pallet exchange.

🧠 Key Features & Technological Advantages

✅ Comprehensive Automation – All critical stages are controlled by PLC and touch-screen HMI, minimizing manual intervention and human error.

✅ Modular Design – Flexible layout for small, medium, or large production capacities (2,000–24,000 bottles per hour).

✅ Hygienic Construction – All parts in contact with beverages are made of SUS304/SUS316L stainless steel, with smooth welds and CIP spray balls.

✅ High Energy Efficiency – Optimized heating circuits, inverter-driven motors, and heat recovery units lower electricity and steam usage.

✅ Quick Changeover System – Easy to switch between different bottle volumes (250ml–2L) without lengthy downtime.

✅ Precision Control – Each filling head equipped with flow meters and servo drives for consistent liquid levels and minimal spillage.

✅ Smart Data Monitoring – Integrated SCADA or IoT module for remote monitoring, fault detection, and production data visualization.

✅ Compliance & Certification – Meets CE, ISO9001, and GMP requirements; suitable for export and government-approved facilities.

📊 Technical Specifications

| Model | Capacity (BPH) | Filling Type | Bottle Type | Filling Temp | Power (kW) | Dimension (mm) |

|---|---|---|---|---|---|---|

| BPL-2000 | 2,000 | Hot/Cold | PET / Glass | 25–95°C | 12 | 5800×1800×2200 |

| BPL-4000 | 4,000 | Hot/Cold | PET / Glass | 25–95°C | 18 | 6800×2000×2300 |

| BPL-8000 | 8,000 | Hot/Cold / Carbonated | PET / Glass / Can | 25–95°C | 28 | 8500×2200×2500 |

| BPL-12000 | 12,000 | Hot/Cold / Carbonated | PET / Glass / Can | 25–95°C | 36 | 9800×2500×2700 |

| BPL-24000 | 24,000 | All Types | PET / Glass / Can | 25–95°C | 60 | 13000×2800×2900 |

(Custom-made solutions for other capacities are available.)

🍹 Beverages That Can Be Produced

Fruit Juices (orange, mango, apple, mixed pulp)

Flavored Water & Vitamin Drinks

Energy & Sports Drinks

Tea Beverages & Herbal Infusions

Carbonated Soft Drinks (cola, soda, sparkling juice)

Functional Drinks (probiotics, protein beverages)

🧩 Optional Equipment & Upgrades

| Optional Unit | Function |

|---|---|

| CIP Cleaning System | Automatic internal cleaning and sterilization. |

| Bottle Blowing Machine | For PET bottle forming and supply. |

| Deaeration Tank | Removes oxygen to prevent oxidation. |

| Carbonation Unit | Adds CO₂ to create sparkling drinks. |

| Nitrogen Injection System | Maintains flavor and extends shelf life. |

| Bottle Sterilizer | High-temperature spray or steam sterilization for bottle interior. |

| Automatic Palletizer | For efficient stacking and packing at end of line. |

🏭 Application Fields

This beverage production line is widely used in:

Beverage manufacturing plants

Bottling & co-packing factories

Juice and soft drink producers

Water and tea beverage industries

Functional beverage OEM projects

Whether you are setting up a new plant or upgrading an existing facility, our line can be tailored to your space, capacity, and product recipe requirements.

💡 Investment Value & ROI Analysis

Low Operating Cost: Advanced automation reduces labor by 60% and saves up to 30% energy.

High Output Efficiency: Continuous production and rapid CIP cleaning ensure over 90% line uptime.

Stable Quality: Temperature, pressure, and mixing precision guarantee consistent beverage taste and clarity.

Fast Payback: Average ROI period ranges between 12–18 months, depending on market capacity.

🌍 Why Choose Us

✔ 15+ years of beverage machinery experience

✔ Delivered 500+ turnkey beverage lines globally

✔ Custom solutions for bottle type, recipe, and automation level

✔ Strong after-sales support, including installation, training, and remote service

✔ Complies with CE / ISO / HACCP / GMP standards

📦 Delivery & Service

Delivery Time: 40–60 working days (depending on configuration)

Installation & Commissioning: On-site or online guidance available

Warranty: 1 year with lifetime technical support

Spare Parts: Supplied for 10 years after delivery

Must-read blogs for bosses