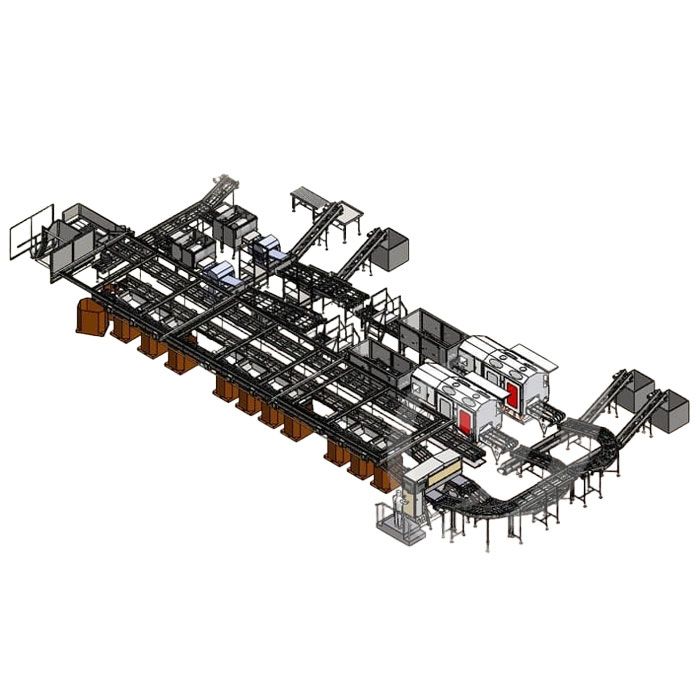

The Braised Pork Belly Can Production Line is a fully automated system designed for large-scale meat processing factories producing braised, stewed, or ready-to-eat canned pork belly.

This line integrates advanced technology for cutting, cooking, filling, sealing, sterilizing, and packaging, ensuring high productivity, food safety, and consistent flavor retention.

Manufactured with food-grade SUS304/316 stainless steel, this system meets HACCP, ISO22000, and GMP standards — ideal for meat canning factories aiming for export-level quality and long shelf life products.

Production Process Flow

Meat Cutting and Preparation

Fresh pork belly is trimmed and cut into standardized cubes or slices by an automatic cutting machine.

The system ensures consistent portion size for even cooking and packaging.

Cooking and Braising Unit

Automatic braising kettles cook pork belly with sauce and seasonings.

Uniform heating ensures authentic taste and texture with reduced manual labor.

Canning and Filling

The cooked meat and sauce are filled into cans or jars using a precise metering filling system.

Ensures uniform product weight and ratio between meat and sauce.

Vacuum Seaming and Sterilization

Vacuum seamer ensures air-tight closure to prevent contamination.

Retort sterilizer (steam or water spray type) eliminates bacteria and ensures long shelf life.

Cooling, Drying, and Labeling

Continuous cooling tunnel prevents overcooking.

Automatic drying, labeling, and packing systems prepare the product for distribution.

Key Equipment in the Line

Automatic Meat Cutting Machine – Uniform pork belly cube/slice cutting for consistent quality.

Cooking & Braising Kettle – Jacketed or steam kettle with automatic stirring and temperature control.

Automatic Filling Machine – High accuracy for both solid and liquid filling.

Vacuum Can Sealing Machine – Ensures air-tight and hygienic packaging.

Retort Sterilizer – Steam or water spray sterilization for long-term shelf stability.

Cooling Conveyor & Labeling Machine – Efficient cooling and labeling in continuous flow.

Technical Highlights

Full PLC automatic control with touch-screen interface.

Constructed from SUS304/316 stainless steel to guarantee food hygiene.

Suitable for tin cans, aluminum cans, or glass jars.

Adjustable production capacity: from 500 to 10,000 cans/hour.

Energy-efficient design with steam and water recycling system.

Optional automatic sauce mixing and dosing system for consistent flavor.

Integrated CIP cleaning system for fast sanitation and easy maintenance.

Applications

Canned braised pork belly production

Ready-to-eat meat processing factories

OEM/ODM canned meat brands

Army or emergency food manufacturers

Meat canning plants for export market

Quality Control & Food Safety

The system complies with international HACCP, ISO22000, and GMP standards.

Every contact surface is food-grade, ensuring hygiene and traceability throughout production.

Critical Control Points (CCPs) such as temperature, pressure, and vacuum sealing are continuously monitored.

Why Choose Us

15+ years of experience in canned meat production line manufacturing

Customized layout and design for your specific factory scale and packaging type

Global installation and training services

Long-term after-sales support and spare parts supply

Proven projects in Asia, Europe, and Africa

FAQ — Braised Pork Belly Canning Line

Q1: Can this line process other meat products besides pork belly?

A: Yes, it can be adapted for other cooked meat types such as beef, chicken, or braised ribs by adjusting the cooking and filling modules.

Q2: What types of cans are supported?

A: It supports tin cans, aluminum cans, and glass jars of various diameters and heights.

Q3: What is the sterilization temperature and time?

A: Standard sterilization is 121°C for 40–60 minutes depending on product size and recipe, adjustable in the control system.

Q4: Can I adjust the flavor or sauce ratio?

A: Yes. The automatic filling system allows flexible adjustment of meat-to-sauce ratio according to recipe requirements.

Q5: How is hygiene maintained during production?

A: All equipment is made of stainless steel and supports automatic CIP (Clean-In-Place) cleaning system for fast and safe sanitation.

Must-read blogs for bosses