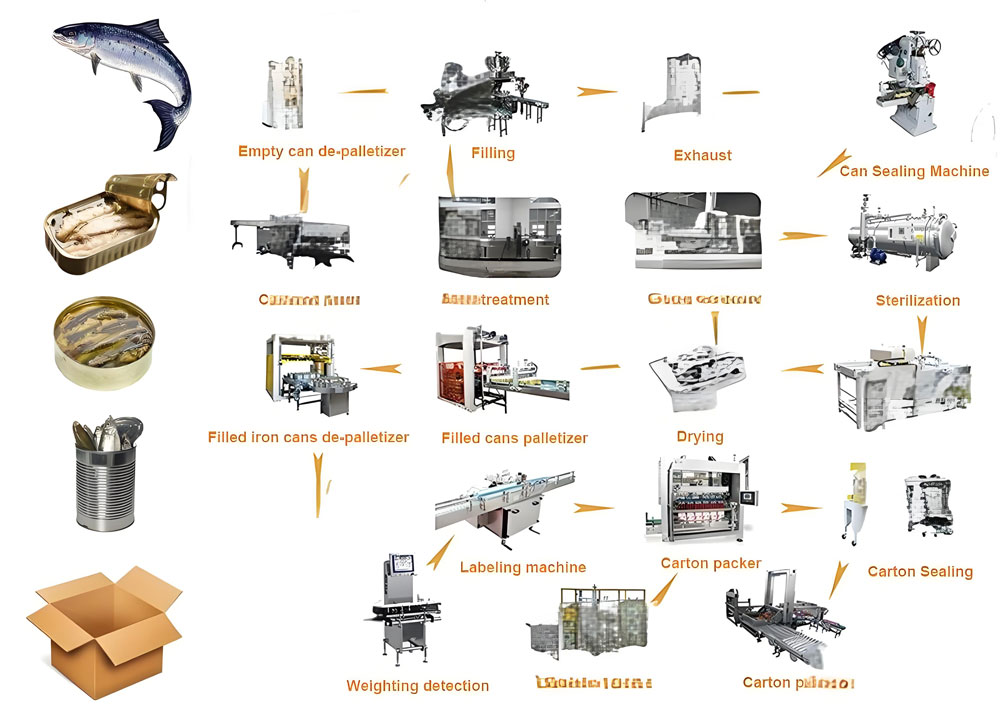

Fish canning production line equipment is a specialized automated production line designed for producing various types of canned fish. It integrates multiple processes, including cleaning, scaling, deboning, cutting, canning, sealing, sterilization, and cooling, enabling a complete production process from raw materials to finished products.

Product Features:

High Efficiency and Automation: Equipped with an advanced automated control system, the production process is automated, improving production efficiency and reducing labor costs.

Quality Assurance: The equipment is made of food-grade stainless steel, meeting food safety standards and ensuring product quality and hygiene.

Flexible Configuration: Different equipment modules can be flexibly configured according to various production needs, meeting the production of different specifications and types of canned fish.

Energy-Saving and Environmentally Friendly: The equipment adopts energy-saving technology, reducing energy consumption and minimizing environmental pollution.

Easy Operation: The equipment has a user-friendly operating interface, making it easy to learn and operate without requiring specialized technicians.

Main Components of the Equipment:

Cleaning Machine: Used for cleaning fish raw materials, removing mud and impurities.

Scaling Machine: Used for removing fish scales, improving the cleanliness of the fish meat.

Deboning Machine: Used for removing fish bones, enhancing the texture of the fish meat.

Cutting Machine: Used for cutting fish meat into specified sizes.

Can Filling Machine: Used for filling fish meat into cans.

Sealing Machine: Used for sealing fish cans to prevent contamination.

Sterilization Machine: Used for high-temperature sterilization of fish cans to extend shelf life.

Cooling Machine: Used for cooling fish cans to reach the appropriate storage temperature.

Applications:

Fish processing enterprises

Food processing plants

Aquaculture farms

Advantages of Choosing Fish Canning Production Line Equipment:

Increased production efficiency and reduced production costs

Ensured product quality and hygiene

Meeting diverse production needs

Energy-saving and environmentally friendly, in line with sustainable development principles

Must-read blogs for bosses