Commercial Food Processing Machinery - Chinese Manufacturer, Factory, Supplier

Commercial Food Processing Machinery forms the backbone of modern food manufacturing plants, providing automation, precision, and hygiene for large-scale production. These machines streamline every step of the process—from ingredient preparation to final packaging—allowing manufacturers to increase efficiency, reduce labor, and ensure consistent product quality. Built from high-grade stainless steel and integrated with intelligent control systems, they meet the rigorous demands of international food safety standards.

⚙️ Product Range

A complete portfolio of Commercial Food Processing Machinery includes:

Meat & Poultry Equipment – cutting, grinding, mixing, cooking, and packaging.

Fruit & Vegetable Processing Systems – washing, peeling, slicing, and canning.

Sauce & Condiment Lines – for ketchup, chili paste, and fruit jams.

Dairy & Beverage Machinery – milk, yogurt, juice, and drink filling systems.

Snack & Bakery Lines – biscuits, pasta, cereal, and baked products.

Each category can be customized or integrated into fully automated production lines depending on the client’s production scale and needs.

🌍 Core Advantages

✅ Automation & Precision – Smart controls minimize human error and improve quality consistency.

✅ Durability & Hygiene – Constructed with 304/316 stainless steel for corrosion resistance and easy cleaning.

✅ Energy Efficiency – Optimized systems reduce energy consumption while maintaining performance.

✅ Flexibility – Modular design supports easy upgrades and process integration.

✅ Compliance – Meets HACCP, ISO22000, and CE standards for global market access.

🧩 Applications

Large meat and poultry processing plants

Frozen food and ready meal factories

Canned fruit, vegetable, and seafood lines

Dairy, beverage, and condiment production facilities

Bakery and snack manufacturing centers

🏗️ Engineering & Support by Qingdao Hongshengyuanlin Co., Ltd.

Qingdao Hongshengyuanlin Co., Ltd. delivers turnkey food processing projects combining equipment design, plant layout, and automation control. With extensive export experience and engineering expertise, the company provides:

Custom project design and factory planning

Equipment manufacturing and installation

On-site training and technical support

Long-term maintenance and spare parts supply

Each system is engineered for efficiency, reliability, and long service life, ensuring clients achieve maximum ROI and operational excellence.

Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Eel Canned Food Production Line

Eel Canned Food Production Line Carrot Processing Line

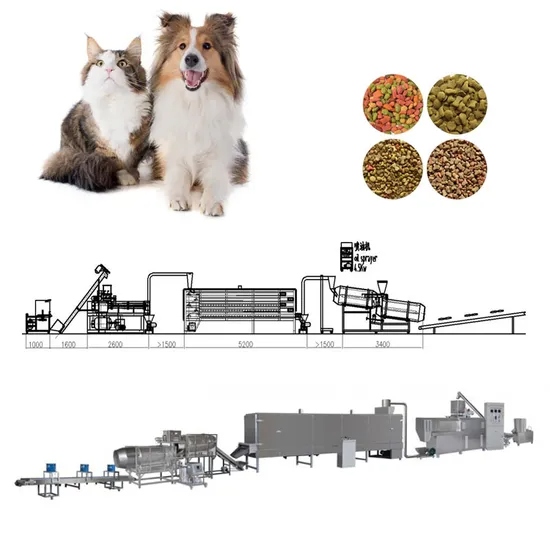

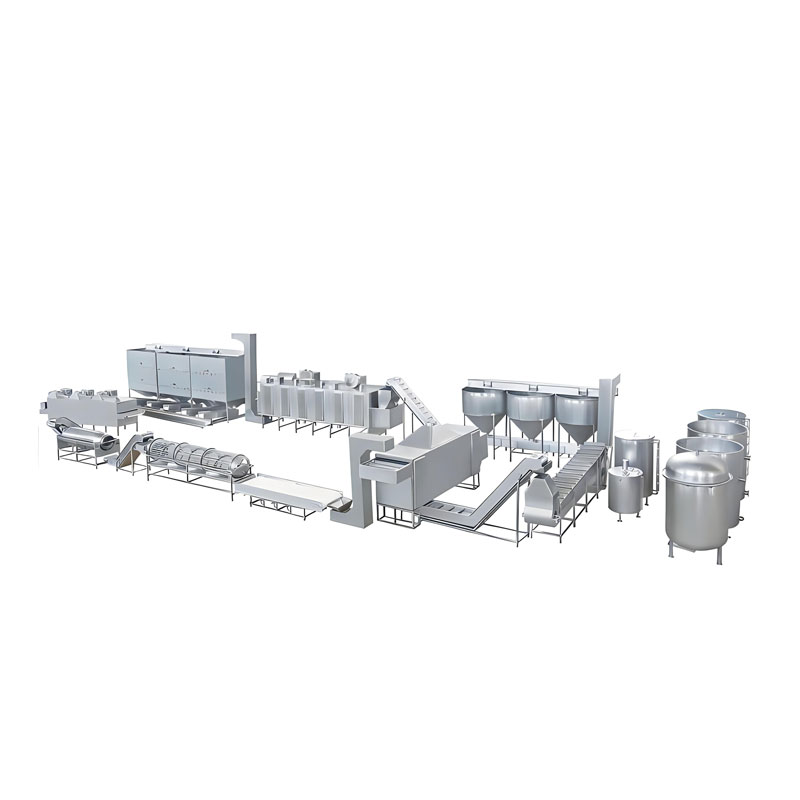

Carrot Processing Line Dry Pet Food Production Line

Dry Pet Food Production Line Potato Processing Line

Potato Processing Line Vegetable Processing Line

Vegetable Processing Line Fish Processing Line

Fish Processing Line Kimchi Production Line

Kimchi Production Line Cucumber Canning Production Line

Cucumber Canning Production Line Hard Candy Production Line

Hard Candy Production Line Remove The Machine

Remove The Machine Chicken Processing Line

Chicken Processing Line AF Series Flake Pellet Ice Machine

AF Series Flake Pellet Ice Machine Automatic Twisting Quantitative Sausage Stuffer Machine

Automatic Twisting Quantitative Sausage Stuffer Machine