142 Gram Canned Fish Production Line - Chinese Manufacturer, Factory, Supplier

The seafood industry demands precision, consistency, and speed. A 142 Gram Canned Fish Production Line is specifically engineered to meet these requirements while optimizing production capacity. Designed for mid to large-scale canning facilities, this system integrates cutting-edge automation to streamline every stage of processing — from raw material handling to final packaging.

The process begins with the careful selection and preparation of fish, ensuring only premium raw materials enter production. Automated conveyors and sorting units handle the fish with minimal manual intervention, significantly reducing labor costs and contamination risks. Once prepared, the fish are precisely cut, filled into 142-gram cans, and sealed with high accuracy. This guarantees consistent weight and airtight sealing, critical factors for maintaining product integrity and shelf stability.

A reliable Canned Fish Production Line Manufacturer focuses on engineering equipment that not only increases output but also maintains superior hygiene standards. These systems are built using food-grade stainless steel, making them durable and easy to sanitize. Advanced sterilization units and quality inspection systems are incorporated to ensure compliance with international certifications like HACCP, ISO22000, and FDA standards.

Speed and accuracy define the performance of a modern 142 Gram Canned Fish Production Line. With programmable controls and intelligent monitoring systems, operators can oversee every stage of production in real-time. This level of automation reduces downtime, optimizes energy use, and minimizes waste, leading to substantial cost savings over time.

Partnering with an experienced Canned Fish Production Line Manufacturer offers more than just equipment supply. It provides access to customized solutions, technical training, and long-term support, helping seafood processors achieve operational excellence.

For businesses looking to expand their market reach and deliver premium canned fish products, investing in a state-of-the-art 142 Gram Canned Fish Production Line is a strategic move. With its unmatched efficiency, compliance readiness, and production versatility, it becomes the backbone of a profitable, sustainable seafood processing operation.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Fruit And Vegetable Canned Production Line

Fruit And Vegetable Canned Production Line Chop Meat Machine

Chop Meat Machine Dual-Roll Steamed Bun Machine

Dual-Roll Steamed Bun Machine Meat Processing Line Equipment

Meat Processing Line Equipment Peanut Butter Production Line

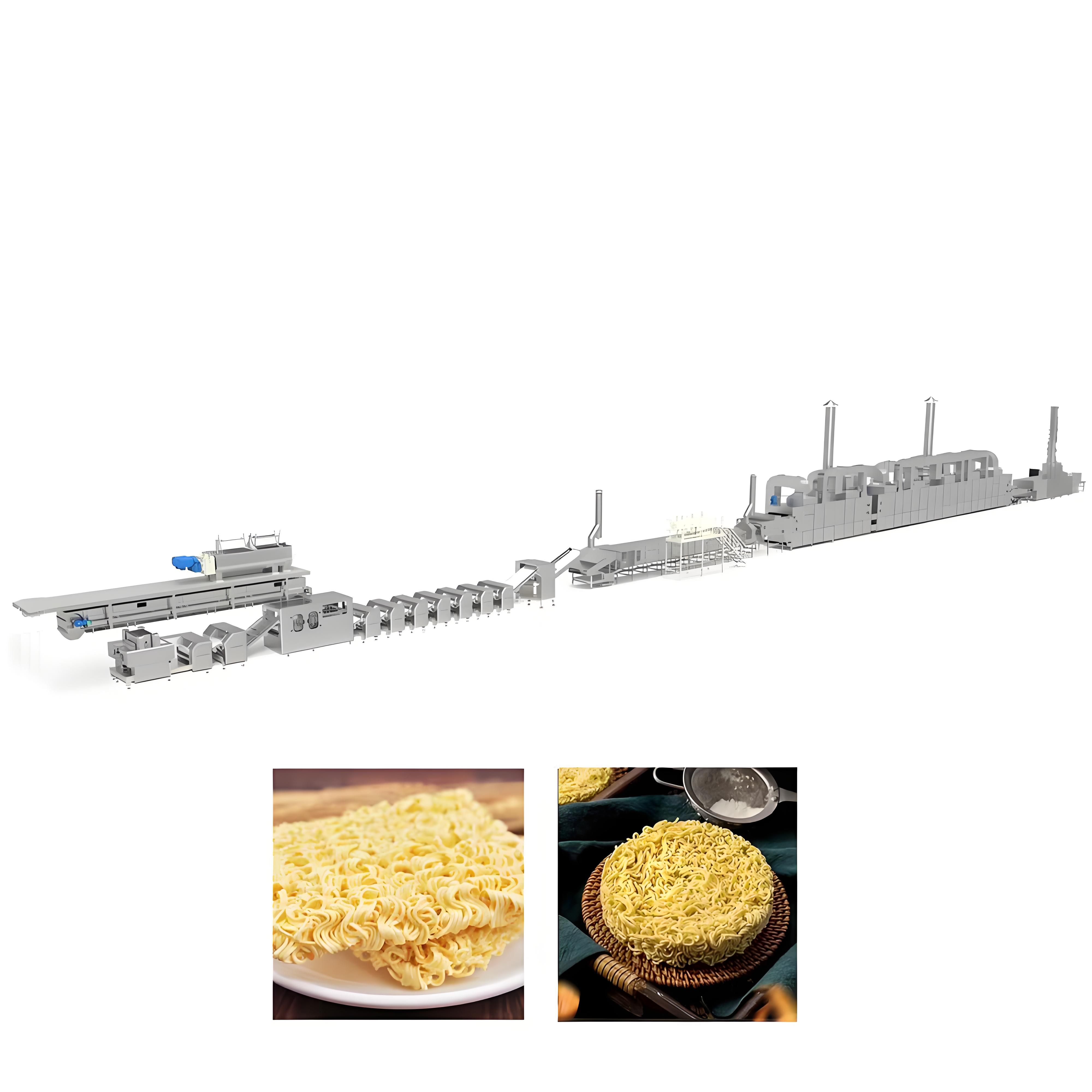

Peanut Butter Production Line Deep-Fried Instant Noodle Production Line

Deep-Fried Instant Noodle Production Line Two-Stage Feeding (Minimum Height) Vertical Packaging System

Two-Stage Feeding (Minimum Height) Vertical Packaging System Cucumber Canning Production Line

Cucumber Canning Production Line