Custom Food Processing Equipment - Chinese Manufacturer, Factory, Supplier

In today’s competitive food industry, one-size-fits-all solutions rarely meet the demands of modern production. Custom food processing equipment offers tailored solutions for manufacturers seeking efficiency, consistency, and flexibility. From snacks and beverages to frozen foods, dairy, and baked goods, these systems are designed to handle unique product requirements and production capacities.

Modern custom food processing lines typically include multiple integrated modules:

Raw Material Handling: Conveyors, hoppers, and automatic feeders streamline ingredient intake and sorting, reducing labor and minimizing waste.

Mixing and Blending: High-precision mixers, kneaders, and homogenizers create uniform bases for sauces, dough, pastes, and powders.

Cooking, Baking, and Frying: Steamers, ovens, fryers, and boilers are customized to product type and throughput, ensuring optimal texture, color, and flavor.

Shaping and Forming: Extruders, molds, cutters, and rollers shape products precisely, from pasta and biscuits to snacks and confectionery.

Cooling, Freezing, and Drying: Blast chillers, IQF freezers, and dehydrators preserve quality, extend shelf life, and maintain texture.

Filling and Packaging: Automatic fillers, sealers, and labeling machines tailor packaging to product type, ensuring hygiene and efficiency.

Automation & Control: PLC panels, touchscreens, and sensors allow real-time monitoring, centralized control, and process optimization.

Leading custom food processing equipment manufacturers focus on scalability, automation, and food safety compliance (HACCP, ISO22000, CE). Whether serving small-scale artisanal producers or large industrial plants, these solutions maximize efficiency while maintaining consistent quality.

Qingdao Hongshengyuanlin Co., Ltd. is a trusted provider of custom food processing equipment in China. The company offers turnkey solutions that combine engineering design, equipment customization, factory layout, installation, and operator training. With successful projects across Asia, Africa, Europe, and the Middle East, Hongshengyuanlin integrates durable materials, energy-efficient design, and advanced automation to deliver reliable, high-performance production lines.

Partnering with a professional custom food processing equipment manufacturer enables businesses to reduce labor costs, optimize production, and innovate with new products. Tailored machinery ensures every line is precisely engineered to meet product specifications, scale efficiently, and maintain competitive advantage in the dynamic food industry.

Types of Custom Food Processing Equipment & Applications

| Category | Main Equipment | Core Function | Typical Applications |

|---|---|---|---|

| Raw Material Handling | Conveyors, hoppers, automatic feeders | Streamline ingredient intake, sorting, and transfer | Vegetables, fruits, meat, grains, powders |

| Mixing & Blending | High-speed mixers, kneaders, homogenizers | Create uniform dough, paste, or liquid base | Sauces, soups, dough, batters, pastes |

| Cooking, Baking & Frying | Steamers, ovens, fryers, boilers | Cook or bake products while ensuring texture and flavor | Snacks, bakery products, fried foods, sauces |

| Shaping & Forming | Extruders, rollers, molds, cutters | Shape products precisely to size and specification | Pasta, biscuits, snacks, confectionery |

| Cooling, Freezing & Drying | Blast chillers, IQF freezers, dehydrators | Preserve product quality, texture, and shelf life | Frozen foods, baked goods, dried snacks |

| Filling & Packaging | Cup fillers, tub fillers, baggers, sealers, labelers | Portion, package, and seal products efficiently | Retail packs, bulk packaging, beverages, sauces |

| Automation & Control | PLC panels, touchscreens, sensors | Monitor production, control parameters, optimize workflow | Fully automated food production lines |

| Quality Control & Inspection | Metal detectors, vision systems, weight checkers | Ensure product safety, uniformity, and compliance | All food products |

| Auxiliary Equipment | Ingredient feeders, conveyors, CIP systems | Support main production and maintain hygiene | Ingredient dosing, product transfer, line cleaning |

Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Eel Canned Food Production Line

Eel Canned Food Production Line Carrot Processing Line

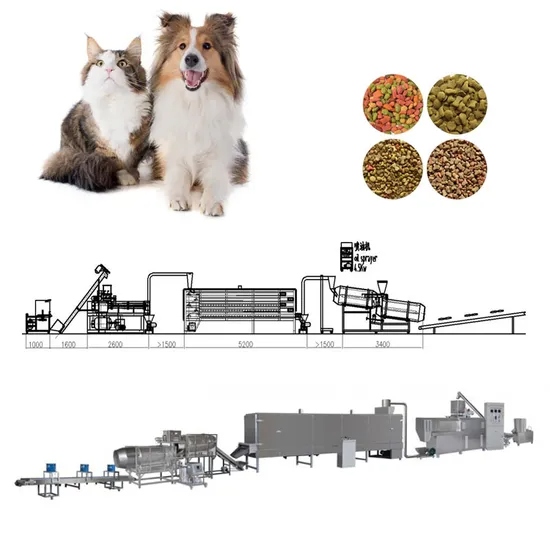

Carrot Processing Line Dry Pet Food Production Line

Dry Pet Food Production Line Potato Processing Line

Potato Processing Line Vegetable Processing Line

Vegetable Processing Line Fish Processing Line

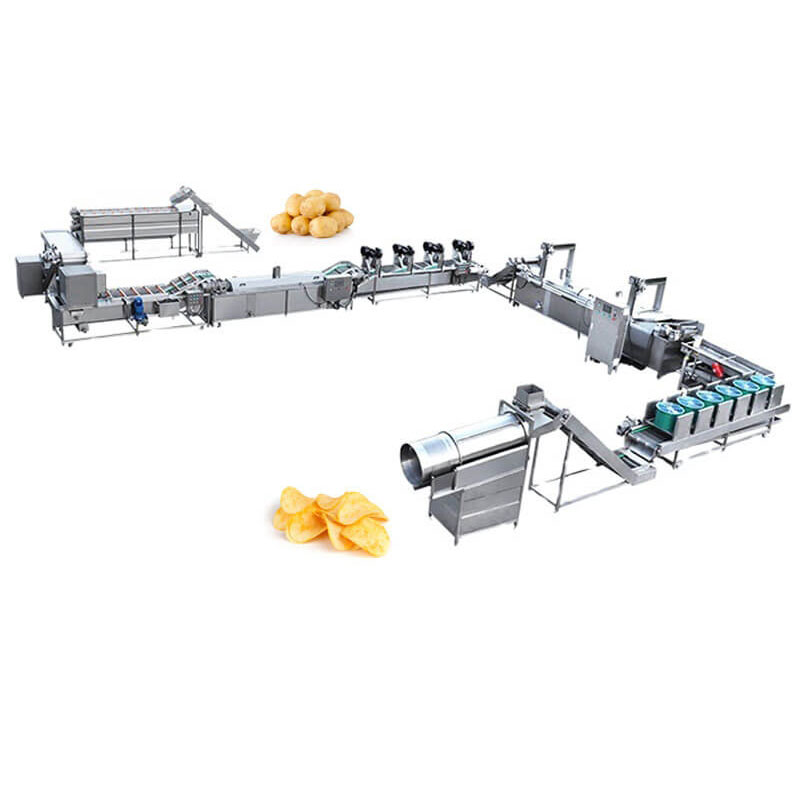

Fish Processing Line Automatic Potato Chips Production Line

Automatic Potato Chips Production Line Egg Canning Production Line

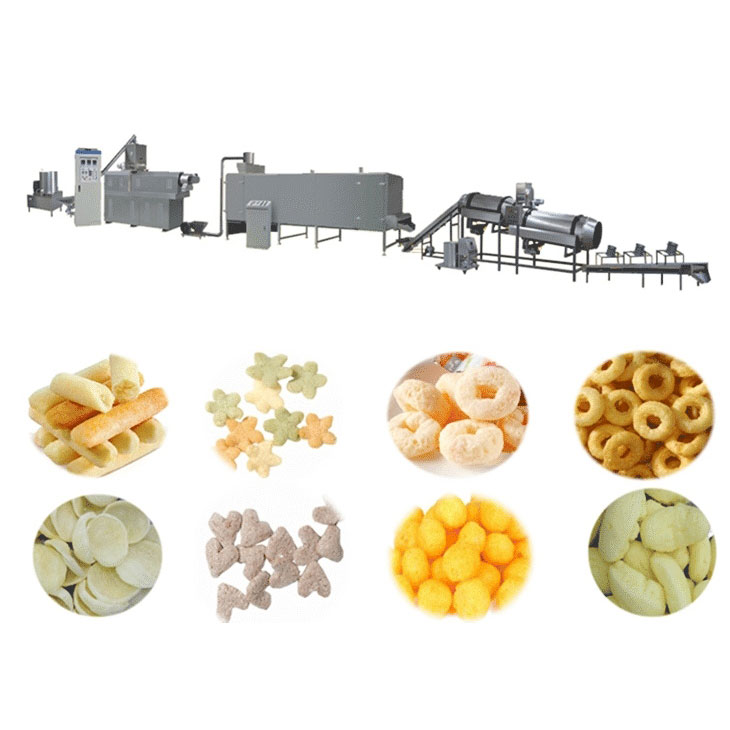

Egg Canning Production Line Snack Production Line

Snack Production Line Frozen Meat Slicer

Frozen Meat Slicer Microwave Pigskin Puffing Machine

Microwave Pigskin Puffing Machine Shrimp Canning Line Equipment

Shrimp Canning Line Equipment  Dough Divider Rounder

Dough Divider Rounder Churros Making Machine

Churros Making Machine