🌿 1. Introduction

The Commercial Honey Processing Equipment is designed for industrial-scale honey extraction, filtration, pasteurization, and packaging, providing a complete solution for honey processors. It ensures high yield, purity, stable quality, and extended shelf life while maintaining honey’s natural flavor and nutrients.

This equipment is suitable for:

Honey processing factories

Food and beverage manufacturers using honey as ingredient

Export-oriented honey producers

Central kitchens and functional food producers

By adopting an automated honey processing line, manufacturers can increase efficiency, reduce labor, and ensure product consistency.

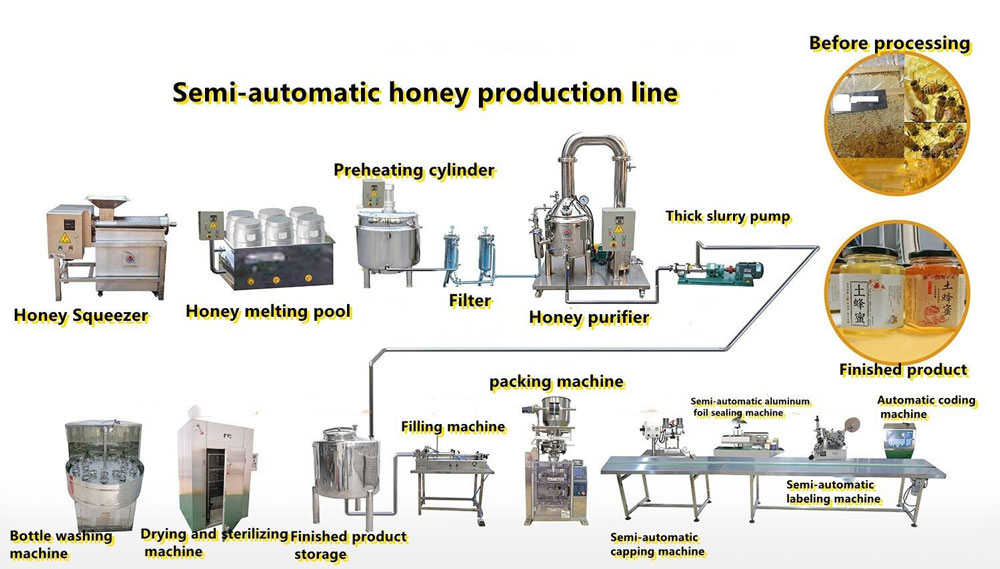

⚙️ 2. Working Principle

Honey Extraction 🍯

Honey is extracted from honeycombs using mechanical honey extractors (centrifugal or hydraulic).

Comb debris and wax are separated during extraction.

Filtering & Clarification 🧹

Honey passes through multi-stage filters to remove impurities, wax particles, pollen, and bee residues.

Optional fine mesh or vacuum filtration ensures crystal-free, clear honey.

Pasteurization & Decrystallization 🔥

Honey is heated to 60–70°C to prevent fermentation and improve fluidity.

Controlled heating preserves natural enzymes and nutrients.

Cooling & Storage ❄️

Pasteurized honey is cooled gradually to room temperature.

Stored in stainless steel tanks with agitators to prevent sedimentation.

Filling & Packaging 📦

Honey is automatically filled into jars, bottles, or sachets.

Sealing, labeling, and batch coding ensure traceability and hygiene.

✅ Advantages of this workflow:

High honey recovery rate

Stable quality and consistent taste

Reduced manual labor and contamination risk

Flexible for different container sizes and packaging types

🚀 3. Key Features

High Automation ⚡

PLC or touch-screen control

Automatic extraction, filtration, heating, cooling, and filling

Hygienic Construction 🛡

Food-grade stainless steel (SS304/316) for all honey-contact parts

CIP (Cleaning-in-Place) system for easy sanitation

Flexible Capacity 📊

Small-scale: 50–200 kg/h

Medium-scale: 200–1000 kg/h

Large-scale: 1000–5000 kg/h

Versatility 🌈

Suitable for raw honey, creamed honey, flavored honey, and blended honey

Optional filtration for organic or high-purity honey

Energy Efficient 🌍

Optimized heating and cooling system reduces energy consumption

Minimal thermal damage preserves natural enzymes and nutrients

📊 4. Technical Parameters

| Model | Capacity (kg/h) | Power (kW) | Heating Temp (°C) | Material | Dimensions (L×W×H, m) | Notes |

|---|---|---|---|---|---|---|

| YL-HP-100 | 100 | 3.5 | 60–70 | SS304 | 1.5×0.8×1.5 | Small-scale, batch operation optional |

| YL-HP-500 | 500 | 7.5 | 60–70 | SS304/316 | 3×1.5×1.8 | Medium-scale, continuous operation |

| YL-HP-1000 | 1000 | 15 | 60–70 | SS316 | 5×2×2.2 | Large-scale, integrated filling system |

✅ Optional Modules:

Multi-stage filtration for ultra-pure honey

Vacuum decrystallization tank

Automatic jar/bottle filling and sealing machine

Temperature-controlled storage tanks

Flavor mixing module for infused honey

🏭 5. Applications

Commercial honey processing factories

Food manufacturers using honey as ingredient

Organic and specialty honey production

Export-oriented honey processing plants

Suitable for:

🍯 Raw Honey | 🍯 Flavored Honey | 🍯 Creamed Honey | 🍯 Blended Honey

💰 6. Operational Benefits & ROI

Labor Saving: Reduces manual extraction, filtration, and packaging work

Consistent Quality: Clear, crystal-free honey with stable viscosity and flavor

Food Safety: Stainless steel construction and CIP system comply with HACCP, ISO, and FDA

High ROI: Continuous processing increases throughput and reduces waste, payback period 1–2 years for medium and large-scale lines

🔮 7. Future Trends

Smart honey production with IoT monitoring for temperature, viscosity, and flow rate

Organic and functional honey products

Energy-efficient pasteurization and decrystallization

Expansion modules for flavored, creamed, or infused honey

✅ 8. Conclusion

The Commercial Honey Processing Equipment provides a complete, efficient, and hygienic solution for honey production at industrial or commercial scale.

Its modular design, automation, and compliance with international standards make it ideal for manufacturers seeking to maximize productivity, maintain consistent quality, and meet growing market demand.

Must-read blogs for bosses