1. Overview

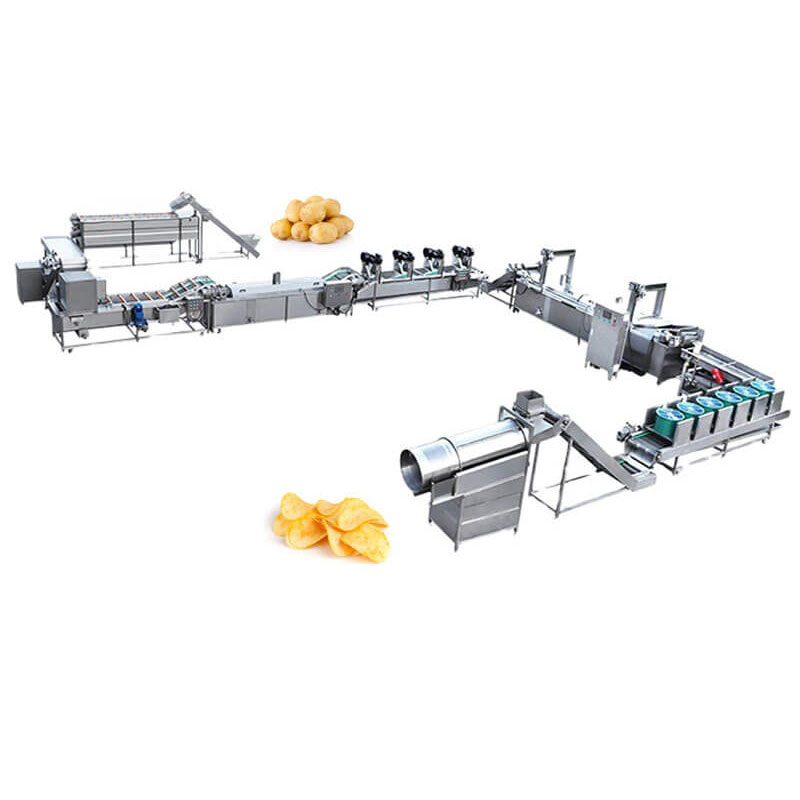

The Crisp Production Line is a fully automated system designed for producing high-quality potato chips and similar fried snacks. It integrates washing, peeling, slicing, blanching, frying, seasoning, and packaging processes in a seamless, hygienic, and energy-efficient flow.

Our turnkey solution helps food processors achieve consistent taste, uniform color, and extended shelf life, while minimizing oil usage and labor costs.

2. Production Capacity

Small Scale: 100–300 kg/h

Medium Scale: 500–1000 kg/h

Industrial Scale: 1500–3000 kg/h or customized

All capacities can be customized according to factory layout and product requirements.

3. Main Processing Flow

Raw Potato Feeding →

Stainless steel conveyor system for even loading.Washing & Peeling →

High-efficiency brush roller machine removes mud and skin without damaging potato flesh.Slicing →

Adjustable thickness slicer ensures uniform cuts, suitable for different crisp styles.Rinsing & Blanching →

Removes starch, prevents browning, and maintains natural potato color.De-Watering →

Centrifugal dehydration reduces oil absorption and improves crispness.Frying →

Continuous fryer with automatic temperature control ensures uniform frying and oil filtration.De-Oiling →

Vibratory or centrifugal de-oiler to remove excess oil and improve product texture.Flavoring & Seasoning →

Rotary drum with automatic powder and oil spraying system for even flavor coating.Cooling & Conveying →

Air cooling conveyor to stabilize texture before packaging.Packaging →

Automatic weighing, filling, and sealing system compatible with nitrogen flushing.

4. Core Equipment

| Equipment Name | Function | Key Features |

|---|---|---|

| Washing & Peeling Machine | Clean and peel potatoes | Brush roller system, SUS304 stainless steel |

| Slicer | Cut potatoes into uniform slices | Adjustable thickness, sharp cutting blades |

| Continuous Fryer | Fry slices evenly | PID temperature control, oil filtration system |

| De-oiling Machine | Remove excess oil | Centrifugal or vibrating type |

| Flavoring Drum | Mix seasoning uniformly | 360° rotating, auto flavor feeder |

| Packaging Machine | Final product sealing | Nitrogen filling, PLC control |

5. Technical Advantages

Hygienic Design: All contact parts are made of SUS304/316 stainless steel to meet food-grade standards.

Energy Efficiency: Equipped with heat recovery systems and insulated fryers to minimize energy loss.

Smart Control: Integrated PLC + HMI touch screen, allowing real-time monitoring of temperature, oil level, and production data.

Easy Cleaning: CIP (Clean-in-Place) system available for automated sanitation.

Oil Management: Advanced oil filtration extends oil life and reduces consumption.

6. Product Quality Features

Uniform color and thickness

Low oil content (<25%)

Crisp texture and long shelf life

Suitable for both potato and non-potato snacks (cassava, banana, taro chips, etc.)

7. Optional Configurations

Energy source: Electric, gas, diesel, or steam heating

Material: SUS304 or SUS316

Continuous or batch frying system

Flavoring system with multiple powder/oil injectors

Customized packaging line integration

8. Applications

Potato chips, sweet potato crisps

Cassava chips, taro chips

Banana or plantain crisps

Mixed vegetable chips

Snack food factories, commercial kitchens, OEM/ODM snack brands

9. ROI & Business Value

Labor Reduction: Up to 60% reduction in manual operations

Oil Saving: 20–30% less oil consumption compared to traditional fryers

Yield Increase: Improved consistency and fewer rejects

Quick Payback: ROI typically within 12–18 months for medium-scale plants

10. Compliance & Standards

CE, ISO9001, HACCP, GMP Certified

Designed according to European food hygiene regulations

Optional UL or CSA certification for North America

11. After-Sales Support

On-site installation & commissioning

Operator training and maintenance guidance

Spare parts supply and online technical support

Global service network with remote diagnostic system

12. Factory Layout Example

We provide 3D layout design and customized plant planning based on your available space, workflow, and capacity requirements.

Our engineers optimize material flow, oil management, and production ergonomics to ensure maximum efficiency.

13. Conclusion

The Crisp Production Line is the ideal solution for modern snack manufacturers seeking automation, consistency, and profitability.

From raw potato to packaged chips, every step is designed to deliver high throughput, superior quality, and food safety compliance.

Must-read blogs for bosses