Corn Flakes Production Machine - Chinese Manufacturer, Factory, Supplier

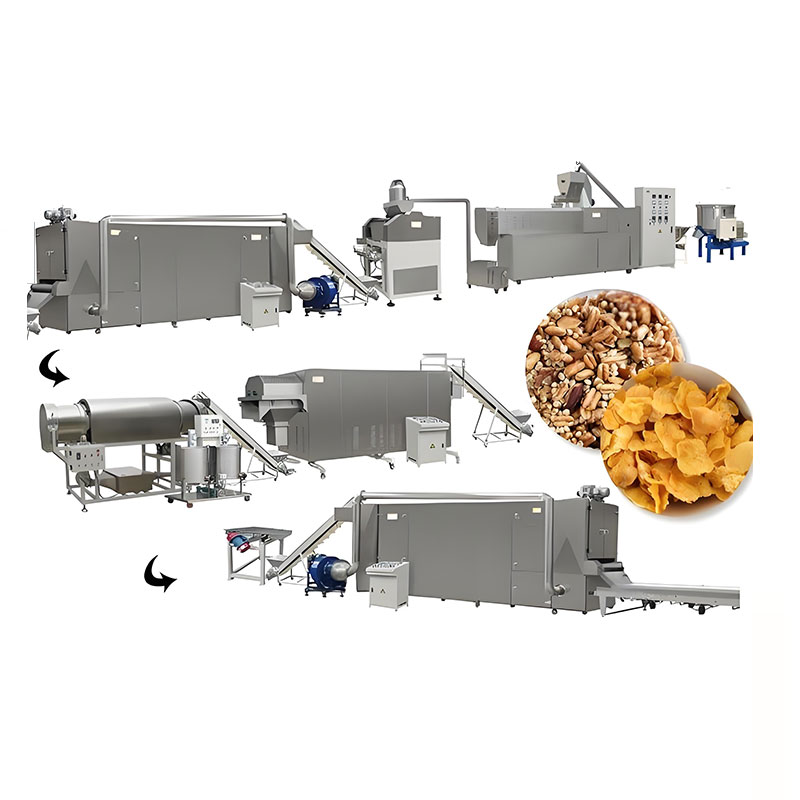

A corn flakes production machine is specialized equipment designed to transform raw corn into crispy, golden flakes ready for packaging and distribution. Widely used by breakfast cereal manufacturers, these machines integrate advanced technology to ensure consistent quality, efficiency, and compliance with international food safety standards.

The process begins with raw corn grits being accurately dosed and mixed with water, vitamins, and minerals. The mixture is then cooked under controlled pressure and temperature to gelatinize the starch, ensuring the right texture and nutritional value. Next, the cooked mass is fed into an extruder, where it is shaped and partially cooked before moving to flaking rollers. These rollers flatten the extruded kernels into thin flakes, which are then toasted or baked in high-capacity ovens to achieve the desired crispness, color, and flavor.

A corn flakes production machine is typically constructed from stainless steel to guarantee durability, hygiene, and ease of cleaning. Automated PLC controls, touch-screen interfaces, and monitoring systems provide precise regulation of cooking, drying, and toasting stages, ensuring uniform results across large production volumes. Optional sugar-coating or flavoring drums can be added to diversify product offerings, including honey-coated or chocolate-flavored flakes.

Energy efficiency and scalability are key features of modern machines. Manufacturers can choose models designed for medium-scale production or fully integrated high-capacity lines capable of continuous operation. Additional modules, such as automatic weighing, packaging, and quality inspection systems, can be seamlessly integrated to create a turnkey solution.

For cereal manufacturers, investing in a corn flakes production machine ensures higher productivity, reduced labor costs, and reliable product consistency. Compliance with HACCP, GMP, and ISO22000 standards provides confidence that every batch meets international market requirements.

By combining automation, robust engineering, and customizable options, a corn flakes production machine enables food producers to meet the growing global demand for breakfast cereals while maintaining competitive efficiency and product innovation.

Corn Flakes Food Production Line

Corn Flakes Food Production Line Multifunctional Food Packaging Machine

Multifunctional Food Packaging Machine Membrane Skinner

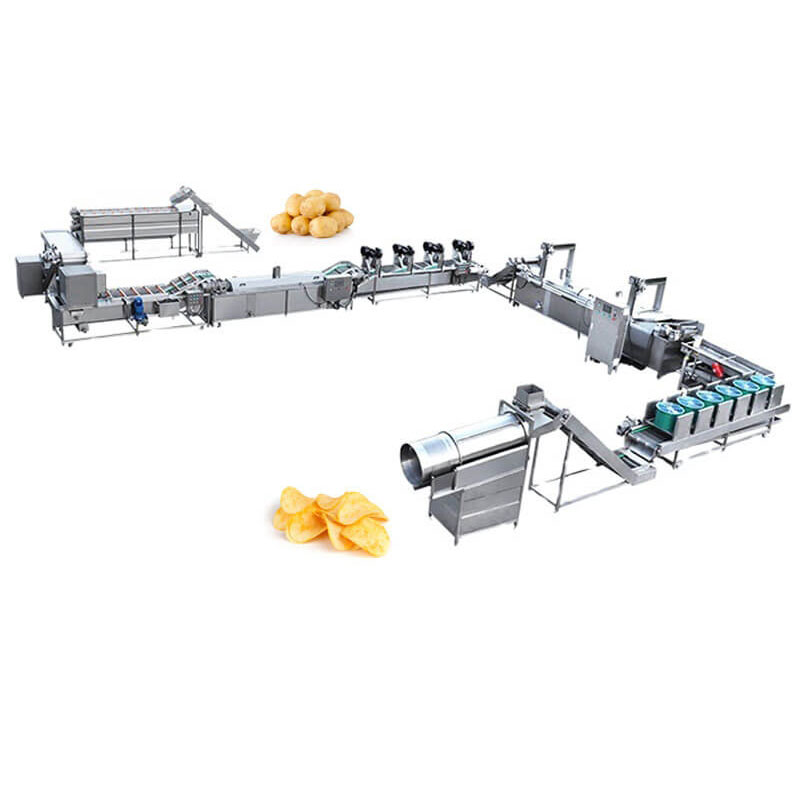

Membrane Skinner Automatic Potato Chips Production Line

Automatic Potato Chips Production Line Egg Canning Production Line

Egg Canning Production Line Meat Processing Line Equipment

Meat Processing Line Equipment Meat Stuffer Machine

Meat Stuffer Machine YL-W-06 Commercial Water Purification Equipment

YL-W-06 Commercial Water Purification Equipment Chicken Nugget Processing Line

Chicken Nugget Processing Line