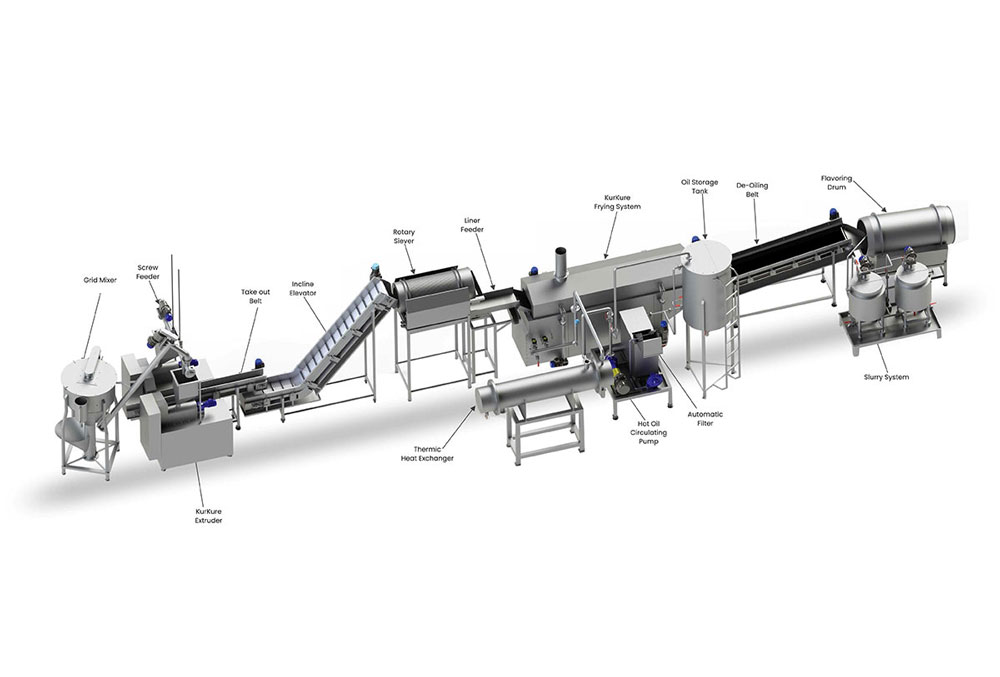

Pasta processing equipment plays a crucial role in the efficient and consistent production of Pastas, providing versatility and reliability in manufacturing. Available in various configurations, these machines cater to different types of Pasta production, from fresh and dried Pastas to instant varieties.

Pasta processing machines come in a range of sizes and capacities to meet specific production needs. For example, common options include machines with cutting widths of 1.5mm, 2mm, and up to 5mm, which allow for a wide range of Pasta styles, including thin vermicelli and broader flat Pastas. The equipment is designed to handle different production volumes, ensuring consistency and quality in each batch.

One of the key features of these machines is the use of high-quality stainless steel construction. This not only ensures hygiene standards are maintained but also guarantees durability, even in high-volume production environments. The machines are also equipped with automatic dough feeding and sheeting systems, which streamline the process from mixing to cutting, minimizing manual intervention.

Another notable feature is the inclusion of custom-designed rollers that adjust to various thicknesses of Pasta dough. This flexibility allows operators to produce Pastas with thicknesses ranging from 1mm to 3mm, ensuring the final product meets specific texture and taste preferences.

To enhance efficiency and meet modern production demands, many Pasta processing machines integrate advanced control systems, allowing for precise temperature and humidity control during the drying process. This ensures Pastas are dried evenly and retain their quality over time.

The appearance of the final product is also a priority, with many machines capable of producing Pastas with a smooth, uniform surface, free from imperfections. This not only improves the aesthetic appeal but also enhances the overall texture and cooking performance of the Pastas. The combination of precision engineering and high-quality materials results in Pasta processing equipment that is both functional and visually appealing in any production setting.

Pasta Processing Equipment Technical Features

High Production Efficiency

Pasta processing equipment is designed for high throughput, allowing for the production of large quantities of pasta in a shorter time frame.

Precise Temperature Control

Advanced temperature control systems maintain optimal processing temperatures for dough consistency, ensuring high-quality products.

Customizable Production Settings

Operators can customize the production process to meet specific product requirements and market demands with adjustable settings.

Hygienic Design

Manufactured from stainless steel with smooth surfaces, ensuring easy cleaning and compliance with food safety regulations.

Energy Efficient

Modern machines incorporate energy-saving technologies, reducing overall power consumption while maintaining performance.

User-Friendly Interface

The intuitive control panel and touchscreen interfaces enhance operational efficiency and reduce training time for operators.

Robust Construction

Built with high-quality materials, designed for durability and to withstand continuous use in industrial environments.

Automated Systems

Equipped with automated feeding and cutting systems, enhancing productivity and reducing labor costs through minimized manual handling.

Comprehensive Benefits of Pasta Processing Equipment

Pasta processing equipment revolutionizes the way pasta is produced in both small and large manufacturing settings. Whether it’s used in commercial kitchens or full-scale production lines, the right pasta machines can boost efficiency, consistency, and overall product quality.

Enhanced Productivity and Efficiency:

Pasta processing machines streamline various stages of production, such as dough mixing, kneading, extruding, cutting, and drying. Automated equipment reduces manual work, allowing facilities to significantly increase output without compromising quality. A single machine can process hundreds of kilograms of dough per hour, greatly speeding up production times compared to traditional methods.

Key Features:

- Automated cutting for perfect pasta shapes and sizes.

- Consistent dough mixing for uniform quality.

- Efficient drying systems that preserve texture and flavor.

Quality Control and Product Uniformity:

One of the greatest benefits of modern pasta processing equipment is the ability to produce uniform batches, ensuring that each pasta shape—from spaghetti to lasagna sheets—meets precise quality standards. The control systems on these machines allow operators to fine-tune every aspect of the process, ensuring consistent texture and appearance, critical for brand reliability.

Cost-Effectiveness Over Time:

Although the initial investment in pasta processing equipment may be substantial, it quickly pays for itself through reduced labor costs, increased efficiency, and minimized waste. By automating the majority of tasks, manufacturers can save on operational expenses and meet growing demand without scaling their workforce.

Additional Advantages:

- Durable stainless steel construction ensures long-lasting use.

- Easy-to-clean surfaces that maintain high hygiene standards.

- Energy-efficient models that reduce operational costs.

Explore our range of premium pasta processing equipment. Contact us today to find the perfect solution for your production needs.

Maintenance and Care Tips for Pasta Processing Equipment

1、Regular Inspection and Cleaning:

- Cleaning: Always clean all parts of the equipment after each use, especially those in direct contact with food. Use mild detergents and soft cloths to avoid damaging the equipment.

- Inspection: Regularly inspect for wear and tear on parts like gears and blades to ensure they are in good condition.

2、Lubrication:

- Ensure that all moving parts are properly lubricated. Add lubricating oil or grease according to the manufacturer’s recommendations to reduce friction and wear.

3、Calibration and Adjustment:

- Regularly check the calibration of the equipment to ensure it operates to specified standards. Make necessary adjustments to maintain performance and production efficiency.

4、Electrical System Checks:

- Regularly inspect the electrical system, including cables, switches, and motors, to ensure there are no loose or damaged components. Repair or replace any issues immediately.

5、Maintenance Records:

- Keep detailed records of all maintenance activities, including the timing and nature of each service, repair, and part replacement. This helps in tracking the equipment’s maintenance history and preventing potential issues.

6、Professional Maintenance:

- Regularly invite professional technicians to perform comprehensive checks and maintenance to ensure the equipment remains in optimal working condition.