Top 8 Brands of Large-Scale Fish Canning Production Lines: 2025 Buyer’s Guide

Hey there, passionate food processing trailblazers! In the thrilling $32.8 billion canned fish market, picking the perfect brand for your large-scale fish canning production line is like supercharging your factory with rocket fuel. With global seafood consumption skyrocketing to a whopping 210 million tons by 2025, canned fish is the star of convenient, long-lasting goodness, and it's exploding in popularity. These powerhouse lines can handle 100,000 to 500,000 cans a day, slashing costs, boosting efficiency, and keeping everything spot-on with HACCP, FDA, and EU safety standards. This guide, fueled by the freshest industry data and expert vibes, is tailor-made for factory bosses, procurement wizards, and supply chain superheroes. We'll dive into what makes these lines tick, spotlight global top brands with juicy details, pros/cons showdowns, and real-life success stories that'll get you pumped. Whether you're scaling up your empire or launching a massive new operation, let's uncover the stories behind these production beasts—grab your coffee, it's a 15-minute adventure!

What’s a Large-Scale Fish Canning Production Line, Anyway?

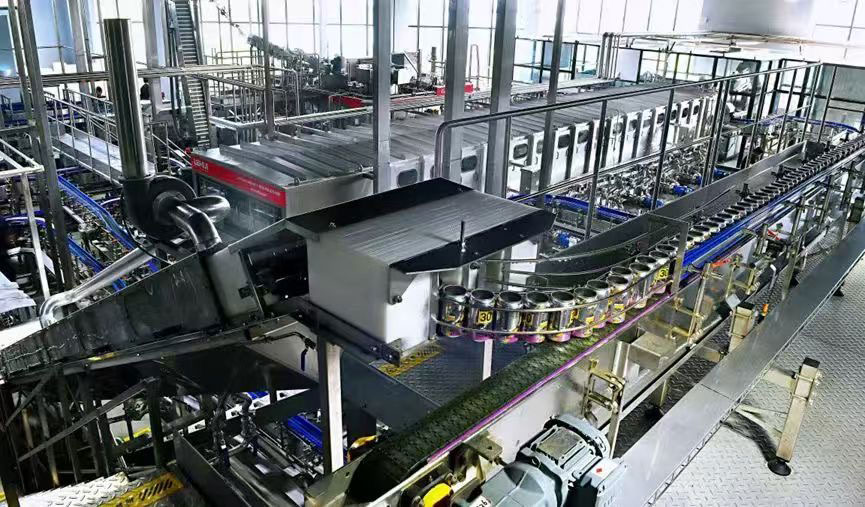

Before we geek out on brands, let's get excited about the basics: A large-scale fish canning production line is a super-integrated automation marvel that turns raw fish into shelf-ready treasures from start to finish. Unlike small or mid-sized setups (under 50,000 cans a day), these bad boys are built for high-volume factories, cranking out 50,000 to 500,000+ cans daily—or more! They thrive on automation, modularity, and smart controls, cutting labor costs by up to 50% while nailing product consistency and safety.

Core Features That Make These Lines Epic

These aren't just machines—they're tech ecosystems buzzing with innovation. Here's what sets them apart, so you can spot the perfect fit for your factory:

- Massive Capacity and Scalability: They run 24/7 non-stop, handling everything from tuna and sardines to salmon. Modular designs let you upgrade on the fly, like expanding from basics to IoT-smart monitoring.

- Automation Awesomeness: Powered by PLCs (Programmable Logic Controllers) and AI algorithms, they automate from washing to sterilizing. Picture a filler zipping through 300 cans a minute, precisely adding fish chunks and sauce—no waste, all wow!

- Materials and Compliance Champs: Food-grade SUS304 or SUS316 stainless steel that's corrosion-proof and easy to clean. They meet global standards like CE, ISO 22000, and HACCP to dodge contamination drama.

- Energy-Saving and Eco-Friendly Vibes: In 2025's green wave, many lines feature heat recovery systems, slashing steam use by 20%+. They even support sustainable packaging like recyclable aluminum cans.

- All-in-One Components: From hydraulic unloaders and washers to gutting machines, precise fillers, auto-sealers, high-pressure retorts, coolers, and labelers. Sensors keep tabs in real-time, ensuring that F-value (sterilization strength) is always on point.

Why go big? FAO data shows high-volume factories using these lines boost efficiency by 30-40%, drop reject rates to under 1%, and even offer remote diagnostics to minimize downtime amid global supply hiccups. Imagine transforming your manual setup into a sleek smart factory—output doubles, costs plummet. That's the magic!

Large vs. Small/Mid-Sized Lines: Quick Showdown

To make it crystal clear, check out this handy table comparison:

| Feature | Large-Scale Lines | Small/Mid-Sized Lines |

|---|---|---|

| Daily Capacity | 50K-500K+ cans | <50K cans |

| Automation Level | Full-auto/smart | Semi-auto/manual |

| Initial Investment | $200K-$1M USD | $50K-$200K USD |

| Best For | Export-driven mega-factories | Startups or local ops |

| Energy Efficiency | High (heat recovery) | Medium |

| Maintenance Complexity | Medium (remote support) | Low |

If you're a high-output hero, these large-scale brands are your ticket to glory. Now, let's jump into the main event: the world's top brands!

Top Brands Spotlight: Dive into the Leaders

In 2025, the battle for large-scale fish canning production line supremacy is fierce, with global innovators each bringing their A-game. From Spain's creative geniuses to China's customization kings, we've handpicked 8 standout brands based on market dominance, user raves, and tech breakthroughs. These aren't just suppliers—they're partners offering full lines, tailoring, and stellar support. Let's explore each one with history, star products, pros/cons, pricing, and inspiring real-world tales to fire you up!

Hermasa (Spain): The World Champion of Canned Fish Machinery

Born in 1972, Hermasa is Spain's iconic powerhouse, renowned for innovation and rock-solid reliability. They specialize in tuna and sardine lines, exporting to 80+ countries. Key stars include their full-auto tuna processing lines (from gutting to sterilizing) and modular sardine systems, handling 10 tons of fish per hour.

- Pros: Cutting-edge tech like patented vacuum sealing for longer shelf life; ultra-automated for 35% efficiency gains; eco-designs with wastewater recycling.

- Cons: Premium pricing not for tight budgets; longer install times (needs pro teams).

- Pricing Range: Full large-scale lines $500K-$1.5M USD.

- Case Study: Picture this: In a bustling tuna export factory on Bangkok's outskirts, the old manual line was choking at 80,000 cans a day, with 5% fish waste and picky EU buyers griping about quality. Boss Khun swapped in Hermasa's full setup, and boom—auto-washers streamed fresh tuna like a river, patented retorts sealed perfection. In just three months, output rocketed to 150,000 cans, rejects plunged to 1%, and EU orders surged 25%. Workers beam: "Hermasa turned our line into a precision clock—maintenance is a breeze, and we're exporting with confidence!"

Hermasa is ideal for international powerhouses chasing top-tier tech—if exports are your jam, this brand's a winner!

JBT Corporation (USA): The Tuna Pro's Go-To

Founded in 1884 as John Bean Technologies, JBT is America's veteran food machinery titan, excelling in fish processing. Their Steritort sterilization systems shine in large-scale lines, batching thousands of cans with safety locked in.

- Pros: Top-notch sterilization with precise F-value control; worldwide service for lightning-fast support; AI monitoring predicts 90% of issues.

- Cons: Import-dependent parts hike costs; steep training curve for operators.

- Pricing Range: Complete lines $300K-$1M USD.

- Case Study: At a classic sardine plant in sunny California, manual sterilization was a nightmare—temp swings caused recalls, output stalled at 50,000 cans daily, and overtime was endless. Enter JBT's Tuna Auto Weight Control system: AI fine-tuned fills, retorts nailed high-heat precision, keeping every sardine batch fresh as the ocean. Output exploded 40% to 70,000 cans, rejects hit 0.5%, and FDA audits? Smooth sailing. The manager cheers: "JBT's like a smart sidekick—freed us from chaos, now our products sparkle on shelves!"

JBT rules the North American scene—if sterilization's your focus, this brand delivers peace of mind.

Zhoushan Willman Machinery (China): The Value-Packed Automation Pioneer

Nestled in China's fish-processing hub Zhoushan since 2005, Willman focuses on export-ready large-scale lines. Their WM series offers full-auto from raw to packed, perfect for salmon and tuna.

- Pros: Killer value with Euro-level automation; super-flexible customizing for your layout; energy savers cut power bills 15%.

- Cons: Lesser-known globally; international support via agents.

- Pricing Range: $200K-$600K USD.

- Case Study: In a humid Ho Chi Minh City outskirts factory, manual lines slogged like mud at 60,000 salmon cans a day, wasting energy left and right. Boss Lan brought in Zhoushan Willman's auto setup, and magic unfolded: Hydraulic unloaders zipped fresh catches, eco-retorts guarded like sentinels. Output jumped to 100,000 cans, costs dropped 20%, and Southeast Asia exports boomed. Lan recalls: "Willman's like a trusty pal—turned our noisy chaos into smooth harmony, freeing us to dream up new flavors!"

As a Chinese gem, Willman balances performance and price like a pro.

Levapack (China): The Packaging Innovator Extraordinaire

Launched in 2010 from Guangdong, Levapack leads China's canned packaging charge. Their large-scale lines spotlight end-stage magic like auto-labeling and smart packing, switching between pull-tabs and tins effortlessly.

- Pros: Advanced packing with AR QR tracing; modular for easy growth; wallet-friendly with quick ROI (1-2 years).

- Cons: Weaker on front-end processing (pair with others); limited English docs.

- Pricing Range: $150K-$500K USD.

- Case Study: In Penang, Malaysia's traditional cannery, outdated packing made products look dated, capping at 40,000 cans daily with peeling labels turning off buyers. Levapack's auto-seal and label system revamped it all: High-res printers added vibrant QRs for source tracing. Sales soared 30%, transforming the dim warehouse into a modern hub. Boss Ahmad exclaims: "Levapack didn't just preserve our cans—it made them stylish stars on shelves!"

Levapack shines for trend-savvy factories riding 2025's sustainable packaging wave.

CFT Group (Italy): Europe's Sterilization Ace

Since 1945, Italy's CFT Group has mastered retorts and fillers. Their Raytec lines for large-scale canning zoom at 500 cans per minute.

- Pros: High-efficiency continuous sterilization; strict EU standards for seamless exports; vision detection dodges contaminants.

- Cons: Pricey; needs European engineers for setup.

- Pricing Range: $400K-$1.2M USD.

- Case Study: By Barcelona's sea-breezy docks, a sardine factory's old retorts caused spoilage woes, limping at 80,000 cans a day with EU inspections blocking progress. CFT's continuous line hit like sci-fi: Vision scanners eyed every fish, high-pressure retorts sterilized flawlessly. Output doubled to 160,000 cans, certifications flew through, turning stress into triumph. Manager Maria shares: "CFT's like an Italian artisan—now our sardines export worldwide with Mediterranean flair!"

CFT's your pick for premium European exports boosting your edge.

Dixie Canner (Spain/USA): The Sealing Maestro and Reliable Ally

Established in 1917 as a Spain-USA joint venture, Dixie excels in canning and sealing. Their large-scale lines deliver vacuum seals for various can types.

- Pros: Ultra-reliable sealing with <0.1% leaks; built to last 10+ years; global parts supply.

- Cons: Slightly behind on full automation; mid-high pricing.

- Pricing Range: $250K-$700K USD.

- Case Study: In Santiago, Chile's tuna plant amid pandemic chaos, supply breaks wrecked old sealers, capping at 70,000 cans with leaks costing orders. Dixie's gear stepped in like a shield: Tough vacuum systems held firm in humidity. Output climbed to 90,000 cans, exports grew 15%, conquering Covid hurdles. Boss Juan raves: "Dixie's our success guardian—now our tuna shines globally!"

Dixie brings old-school reliability with fresh energy!

Qingdao Hongsheng Yuanlin (China): The Customization Champ

China's rising star since 2015, Qingdao Hongsheng Yuanlin specializes in tailored large-scale lines. Their HSYL series integrates everything, ideal for Asian fish like yellow croaker.

- Pros: Ultra-customizable for your scale; competitive pricing; lightning-local support (24-hour response).

- Cons: Building global fame; innovation trails Western giants.

- Pricing Range: $180K-$550K USD.

- Case Study: On Guangdong's coast, a cannery's tight space and peak seasons overwhelmed the old line at 40,000 cans, delaying yellow croaker runs. Qingdao's custom setup fit like a puzzle: Auto-gutters hummed efficiently, smart controls streamlined flow. Output rocketed 50% to 60,000 cans, costs fell 10%, freshness soared. Owner Li boasts: "It's like a bespoke suit—fits our needs perfectly, sending South China Sea flavors worldwide!"

As a local powerhouse, it's great for mid-to-large transitions.

Brand Comparison Table: At a Glance

For easy vibes, here's a quick overview of the top brands:

| Brand | Country | Specialty | Pricing Range (USD) | User Rating (Out of 10) | Recommended For |

|---|---|---|---|---|---|

| Hermasa | Spain | Tuna Processing | 500K-1.5M | 9.2 | International Export Giants |

| JBT Corporation | USA | Sterilization Systems | 300K-1M | 8.8 | North American Compliance Pros |

| Zhoushan Willman | China | Full Automation | 200K-600K | 8.5 | Asian Value Hunters |

| Levapack | China | Packaging Innovation | 150K-500K | 8.3 | Sustainable Packaging Fans |

| CFT Group | Italy | Continuous Sterilization | 400K-1.2M | 9.0 | European Premium Markets |

| Dixie Canner | Spain/USA | Sealing Tech | 250K-700K | 8.7 | Reliable Mid-Size Upgraders |

| Qingdao Hongsheng Yuanlin | China | Custom Services | 180K-550K | 8.6 | Local Transition Heroes |

These span luxury to budget—pick based on your needs and wallet!

2025 Canned Fish Market Trends: Opportunities and Thrills Ahead

Buckle up for 2025—the canned fish market is buzzing at $32.8 billion, set to zoom at a 5.8% CAGR to $54.6 billion by 2034! Driven by crave-worthy convenient proteins and supply smarts, but watch for economic twists and green demands. Here's five electrifying trends to fuel your strategy and keep your lines ahead of the curve.

1. Sustainability and Eco-Packaging Take Center Stage

Eco-conscious consumers are all in—73% of Gen Z crave recyclables! 2025 sees shifts to BPA-free liners and ocean-plastic recycled materials, like EcoFish's premium tins. The global market eyes a 3.5% CAGR to $44.27 billion by 2030. For lines, that means eco-labelers and recycle scanners. Skip this, and you miss TikTok's viral "green tins" buzz!

2. Health and Convenience Fuel the Fire

Post-pandemic, folks love Omega-3-packed sardines and tuna as healthy snacks. The market hits $14.45 billion in 2025, climbing to $18.65 billion by 2030. Spicy or plant-blended flavors rule, sparked by "tinned fish girl summer" on social. Lines need multi-flavor fillers and mini portable cans for urban hustlers.

3. Emerging Markets and Regional Booms

Asia and Latin America are exploding—China and Vietnam lead exports. North America's frozen/canned seafood starts a 1.14% CAGR from 2025, hitting $26.84 billion by 2033. Recession-proof cans surge in tough times, turning challenges into gold. Brands like China's locals shine with localized tweaks to snag shares.

4. **Tech Innovation and Smart Packaging Sparkle

AR labels and NFC chips let folks trace origins and nutrition—boosting repeat buys 15%. Lines must add QR printers for viral marketing. Top brands like Hermasa weave in AI for the win.

5. Challenges: Supply Chains and Economic Vibes

Raw price swings and geo-risks loom, but stellar brands like JBT cut costs via efficient retorts. Overall, the market's poised for $47.1 billion by 2029 with strong CAGR.

These trends scream: Go for sustainable, smart-compatible brands to ride the wave!

How to Pick the Perfect Brand

Choosing a brand isn't guesswork—it's a thrilling strategy! Here's your 2025 checklist to dodge pitfalls and snag the ideal match. Great brands sell more than gear—they build lasting alliances.

- Size Up Your Capacity Needs: Crunch daily output and fish types (tuna needs heavy-duty gutters). Over 100K cans? Hermasa or CFT all the way.

- Vet Certifications and Compliance: Lock in CE/ISO/HACCP. Export pros, grab JBT or CFT to breeze through customs.

- Weigh Support and Maintenance: Global networks like JBT's remote fixes rock; locals like Qingdao Hongsheng Yuanlin respond in 24 hours.

- Budget and ROI Math: Use gains/investment formula. Energy-savers like Zhoushan Willman pay back fast.

- Trend Sync: In 2025, snag AR-label supporters like Levapack for green packaging.

- Hands-On Check: Tour factories or expos, test fits.

Quick FAQs:

- Q: Best for tuna canning? A: Hermasa or JBT—sterilization and processing pros.

- Q: Are Chinese brands solid? A: Absolutely, like Qingdao Hongsheng Yuanlin—value-packed for Asia.

- Q: Cost-cutting tips? A: Modular brands for step-by-step upgrades.

Follow these, and you'll land a competition-crusher!

Wrapping Up: Embrace 2025, Choose Wisely, and Win Big!

Large-scale fish canning production line brands like Hermasa, JBT, and Qingdao Hongsheng Yuanlin are steering the industry toward smart, sustainable awesomeness. This guide's your launchpad to stand out and upgrade your factory game. Remember, investing in the right brand is investing in your future—hit us up for custom quotes, or share your stories!

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?