Fully Automatic French Fries Line - Chinese Manufacturer, Factory, Supplier

High-Efficiency Solution for Large-Scale Potato Processing

Our Fully Automatic French Fries Production Line is an industrial-grade, continuous processing system designed for food manufacturers, frozen food suppliers, and quick-service restaurant (QSR) distributors. Engineered for precision, reliability, and hygiene, the line transforms fresh potatoes into uniform, crispy fries—ready for freezing, packing, or direct delivery to foodservice channels.

From raw potato reception to final packaging, every step is automated to reduce labor costs, ensure food safety compliance, and deliver consistent product quality on an industrial scale.

Key Process Flow

Potato Reception & Washing

High-capacity destoners, washers, and peeling systems remove soil and debris efficiently.Cutting & Sizing

Adjustable knife systems deliver precise cuts for shoestring, crinkle, or steak fries.Blanching

Inactivates enzymes and preserves texture, with exact temperature & timing control.Drying

Air or belt dryers remove surface moisture to enhance frying consistency.Frying

Continuous fryer with oil filtration system ensures golden, crispy, and low-oil fries.De-oiling & Cooling

Vibration and air-cooling conveyors stabilize product temperature and texture.Freezing (optional)

IQF spiral or belt freezer to lock in freshness and extend shelf life.Weighing & Packaging

Integrated multi-head weighers and baggers for retail or bulk packaging formats.

Why Clients Choose Our Line

✅ Scalable Output: From 500kg/h to 10,000kg/h, tailored to production targets

✅ Consistent Quality: Uniform shape, fry length, moisture, and color

✅ Full Automation: Reduced manual intervention minimizes human error and labor costs

✅ Food Safety Compliant: Built to meet CE, FDA, HACCP, and ISO standards

✅ Energy Efficient & Easy to Clean: Optimized layout with CIP-ready modules

Application Scenarios

Frozen French fries factories

Central kitchens & QSR suppliers

Contract food processors

Export-oriented food production facilities

French Fries Frying Machine

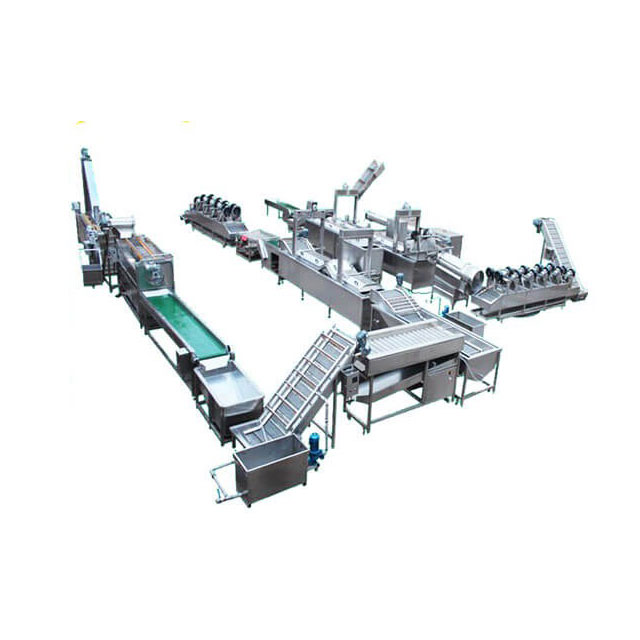

French Fries Frying Machine Small Scale French Fries Production Line

Small Scale French Fries Production Line Frozen French Fries Production Line

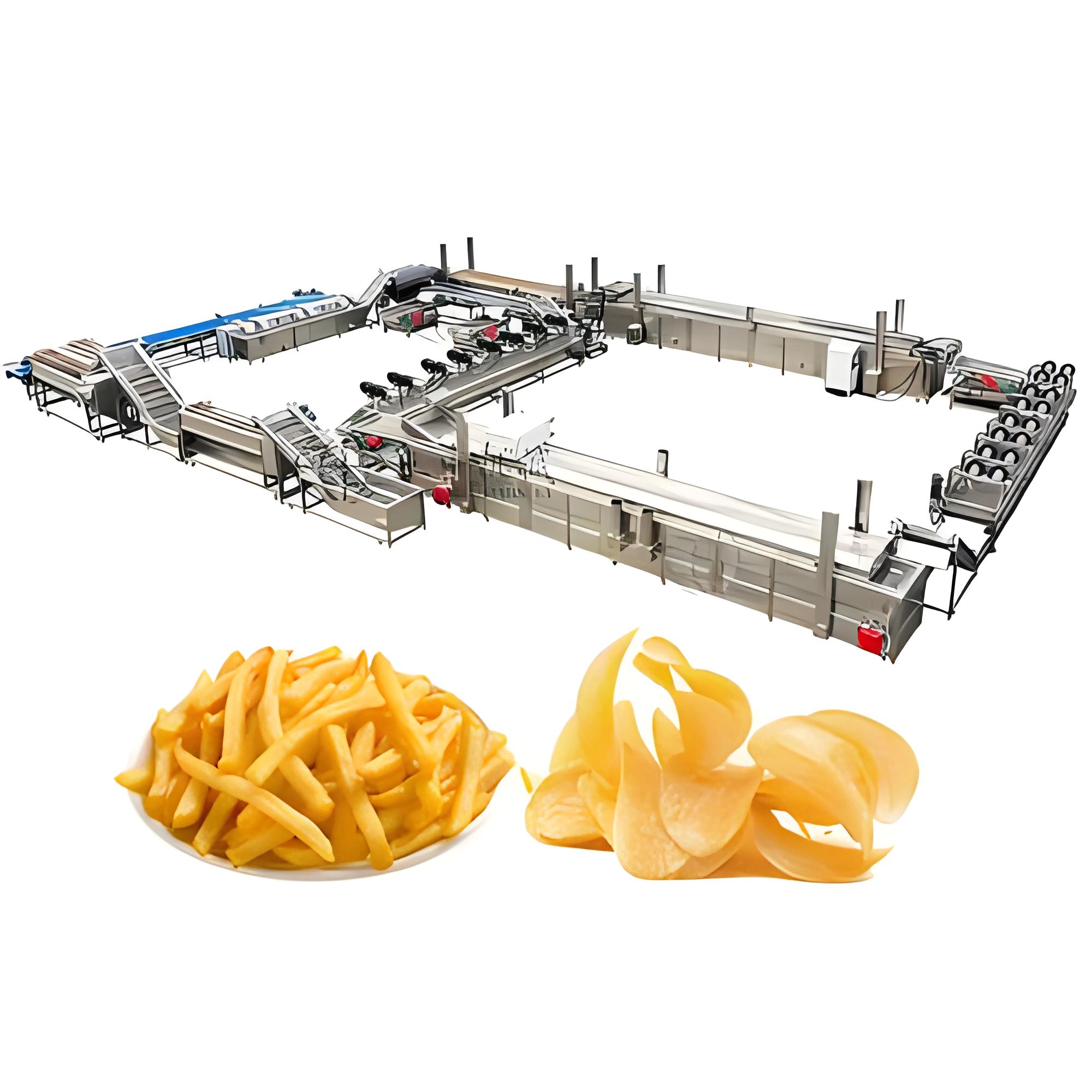

Frozen French Fries Production Line French Fries Production Line

French Fries Production Line Standard Vertical Weighing and Packaging System

Standard Vertical Weighing and Packaging System YL-W-05 Commercial Water Purification Equipment

YL-W-05 Commercial Water Purification Equipment Automatic Rice Production Line

Automatic Rice Production Line Automatic Banana Chips Production Line

Automatic Banana Chips Production Line Model 330 Frequency Conversion High Speed Chopper

Model 330 Frequency Conversion High Speed Chopper Chicken Feet Cutting Machine

Chicken Feet Cutting Machine Fish Speed Cleaning Machine

Fish Speed Cleaning Machine