Automatic Canning Production Line - Chinese Manufacturer, Factory, Supplier

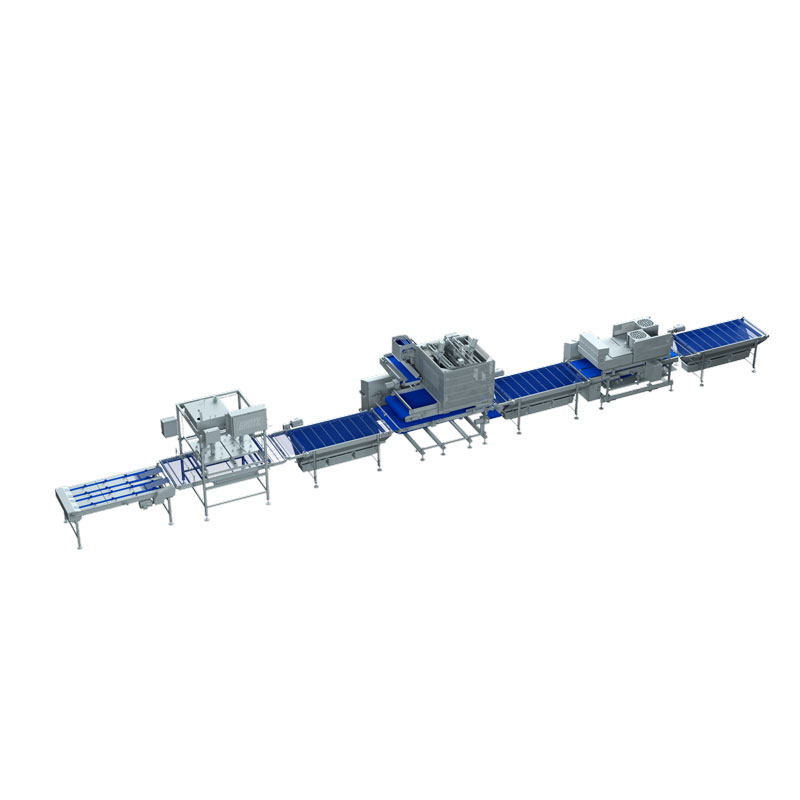

The Automatic Canning Production Line developed by Qingdao Hongshengyuanlin Co., Ltd. represents the next generation of intelligent and efficient canning technology. Designed for large-scale food, beverage, and seafood manufacturers, this fully automated system integrates precision engineering, hygiene control, and digital monitoring to ensure consistent product quality and maximum operational efficiency.

This production line covers the entire process — from raw material preparation to packaging — including cleaning, cutting, filling, seaming, sterilization, cooling, labeling, and cartoning. Each section is seamlessly connected through intelligent conveyors and PLC-controlled modules, enabling smooth material flow and real-time data monitoring throughout the entire production cycle.

Built with food-grade stainless steel (SUS304/316), all components are corrosion-resistant, easy to maintain, and compliant with HACCP, ISO, and CE standards. The automatic filling and seaming systems ensure precise portion control and airtight sealing, minimizing product loss and contamination risk. The retort sterilization system employs advanced temperature and pressure regulation to guarantee product safety while preserving nutrition, flavor, and texture.

Production capacities can be customized — from 3,000 to 30,000 cans per hour — depending on the product type and packaging format. The system supports various can materials such as tinplate, aluminum, and composite cans, making it suitable for fish, meat, vegetables, sauces, beverages, and pet food industries.

A highlight of this line is its smart control system, which integrates touch-screen operation, automatic alarms, and production data recording. This digitalization allows manufacturers to monitor performance, optimize energy consumption, and ensure traceability throughout every production batch.

With years of engineering experience and international project delivery, Qingdao Hongshengyuanlin provides complete turnkey canning solutions — including factory layout design, utility planning, equipment manufacturing, on-site installation, commissioning, and staff training. Our dedicated technical team ensures every system operates at peak efficiency and delivers stable long-term performance.

Choosing the Automatic Canning Production Line means investing in reliability, productivity, and innovation. It empowers food processors to reduce labor costs, maintain uniform quality, and expand market competitiveness through automation, standardization, and sustainable manufacturing technology.

Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Eel Canned Food Production Line

Eel Canned Food Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line Model 200 Frequency Conversion High Speed Chopper

Model 200 Frequency Conversion High Speed Chopper Chicken Slaughtering Machine

Chicken Slaughtering Machine SD Square Ice Series Upright Ice Makers

SD Square Ice Series Upright Ice Makers Dough Roller Machine

Dough Roller Machine Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine YL-508L Aluminum Foil Dedicated Metal Detector

YL-508L Aluminum Foil Dedicated Metal Detector Fully Automated Pizza Production Line

Fully Automated Pizza Production Line Cutting And Stringing Integrated Machine

Cutting And Stringing Integrated Machine