Seafood Processing Equipment Manufacturers - Chinese Manufacturer, Factory, Supplier

Leading seafood processing equipment manufacturers in China, such as Qingdao Hongshengyuanlin Co., Ltd., specialize in designing and manufacturing advanced machinery for fish, shrimp, crab, squid, and other marine product processing. These manufacturers deliver high-performance, automated systems that meet the demanding hygiene and quality standards of global seafood industries.

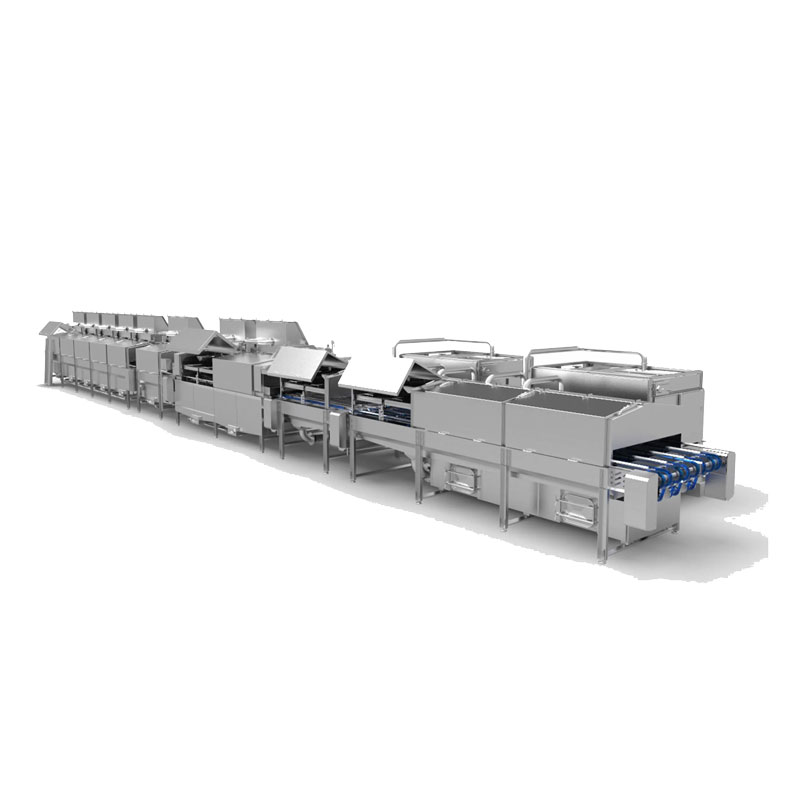

Modern seafood processing requires equipment that can handle delicate raw materials while maintaining product freshness, nutritional value, and uniformity. Manufacturers provide complete processing lines, including cleaning and grading machines, filleting and skinning units, portioning and cutting systems, deboning equipment, vacuum tumblers, IQF freezers, and packaging lines. Each system is built from food-grade stainless steel, ensuring corrosion resistance, durability, and easy sanitation under wet and saline working conditions.

Automation plays a crucial role in today’s seafood factories. Integrated PLC control systems, touchscreen interfaces, and data monitoring ensure precise operation and real-time production tracking. Whether for canned, frozen, or smoked seafood, these machines streamline every step — from raw material handling and cleaning to cooking, sterilization, and final packaging. The result is reduced labor costs, consistent product quality, and improved throughput.

Top seaFood Processing Machinery manufacturers also provide custom turnkey solutions tailored to specific seafood types and plant capacities. Engineering teams design equipment layouts, install complete production lines, and train operators for efficient day-to-day operation. Specialized options such as automatic canning systems, retort sterilizers, and vacuum packaging machines are widely adopted in fish canning factories producing tuna, mackerel, sardine, and anchovy products.

Chinese seafood equipment suppliers have gained strong global recognition due to their cost-effective engineering, export experience, and international certification (including HACCP, ISO, and CE). They support clients across Asia, Africa, South America, and Europe with both single machines and integrated solutions for seafood processing plants, cold storage facilities, and food packaging centers.

By combining technological innovation with deep industry expertise, these manufacturers help seafood producers modernize their production, ensure safety and traceability, and expand their export capabilities. Partnering with a trusted seafood processing equipment manufacturer guarantees reliable operation, higher efficiency, and long-term profitability in the competitive seafood industry.

Types of Seafood Processing Equipment & Applications

| Category | Main Equipment | Core Function | Applications |

|---|---|---|---|

| Fish Processing Line | Cleaning machines, filleting units, skinning machines, portion cutters, deboners | Cleaning, cutting, skin removal, and portion control | Tuna, mackerel, sardine, salmon, anchovy |

| Shrimp Processing Equipment | Graders, peelers, deveiners, cookers, IQF freezers | Sorting, peeling, cooking, and freezing shrimp | Cooked and frozen shrimp production |

| Crab & Shellfish Processing Systems | Steam cookers, shell breakers, meat extractors, washers | Cooking and separating edible crab meat or shellfish | Crab sticks, ready-to-eat seafood |

| Cephalopod Processing Line | Squid cleaning machines, cutting units, blanching systems | Removing skin, viscera, and slicing squid or octopus | Frozen squid rings, seafood mixes |

| Canned Seafood Line | Automatic can washers, fillers, seamers, vacuum exhausters, retort sterilizers | Filling, sealing, and sterilizing seafood in cans | Canned tuna, sardine, mackerel |

| Frozen Seafood Line | IQF freezers, glazing systems, packing units | Rapid freezing and surface protection for freshness | Frozen fillets, seafood blocks, mixed packs |

| Dry & Smoked Seafood Line | Drying ovens, smoking chambers, vacuum sealers | Dehydration and flavor enhancement | Dried fish, smoked salmon, jerky seafood |

| Packaging & Labeling Systems | Vacuum packing machines, tray sealers, labeling and coding units | Product preservation and traceability | Export-grade packaging for retail or foodservice |

| Quality Inspection & Grading Systems | Metal detectors, weight graders, vision sorters | Ensuring quality, uniformity, and food safety | Export inspection lines, HACCP plants |

| Auxiliary & Support Equipment | Conveyors, washing tanks, chillers, air compressors | Production transfer, cleaning, and cooling | Integrated seafood plant operations |

Eel Canned Food Production Line

Eel Canned Food Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line Fish Processing Line

Fish Processing Line Automatic Fish Filleting Machine

Automatic Fish Filleting Machine Fish Slicer Machine

Fish Slicer Machine Fish Food Processing Line

Fish Food Processing Line Shrimp Processing Line

Shrimp Processing Line Shrimp Canning Line Equipment

Shrimp Canning Line Equipment  SD-3000 / SD-4000 Commercial Cube Ice Maker

SD-3000 / SD-4000 Commercial Cube Ice Maker Crushed Ice Machine

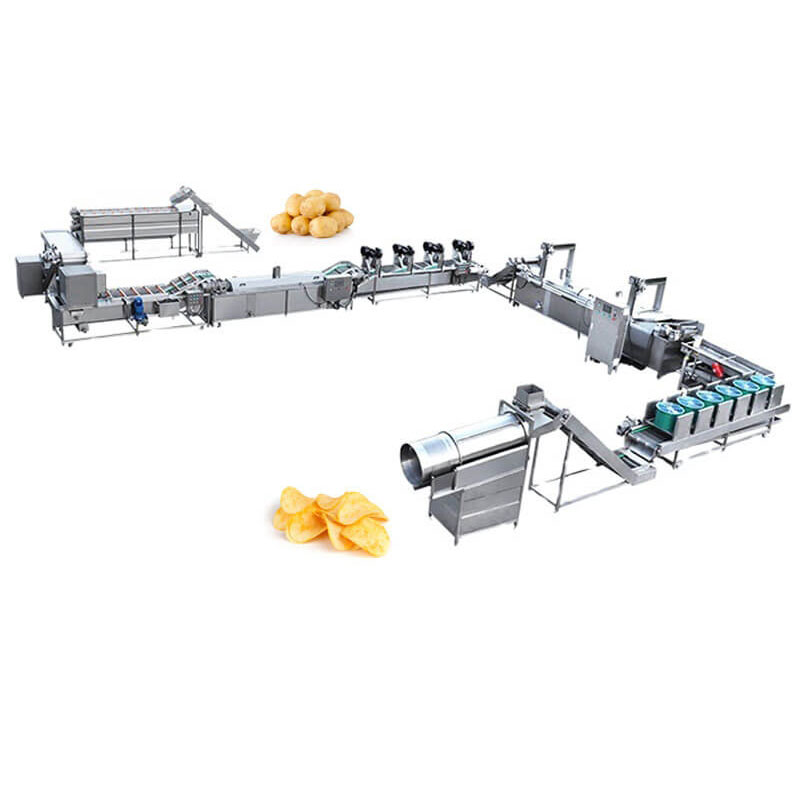

Crushed Ice Machine Automatic Potato Chips Production Line

Automatic Potato Chips Production Line Pork Skin Removing Machine

Pork Skin Removing Machine Beverage Production Line

Beverage Production Line Chicken Feet Peeling Production Line

Chicken Feet Peeling Production Line Big Chicken Feet Peeling Machine

Big Chicken Feet Peeling Machine Sauce Filling Machine

Sauce Filling Machine