Potato Chips Line - Chinese Manufacturer, Factory, Supplier

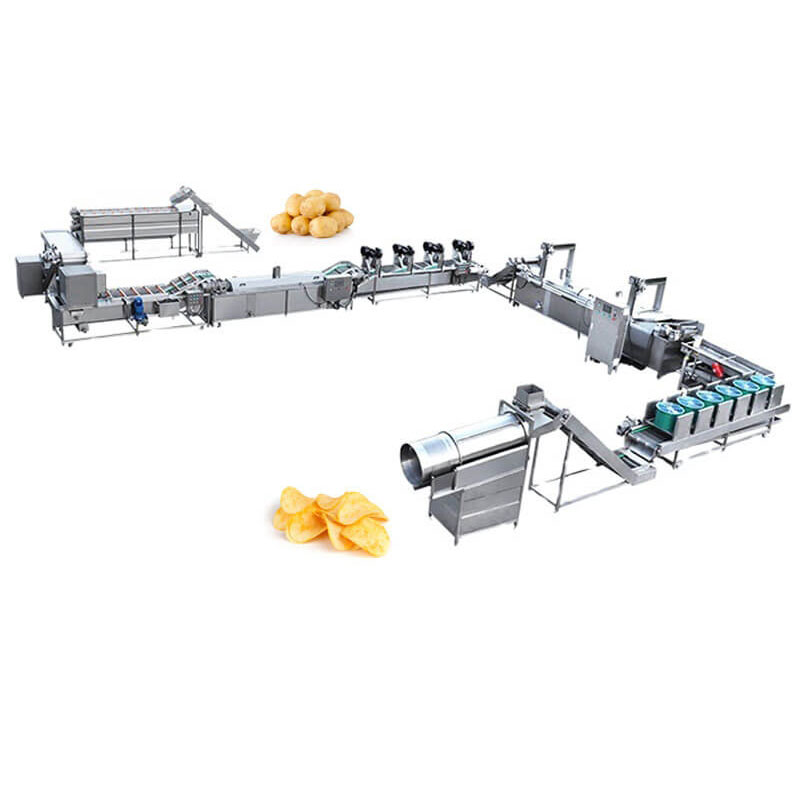

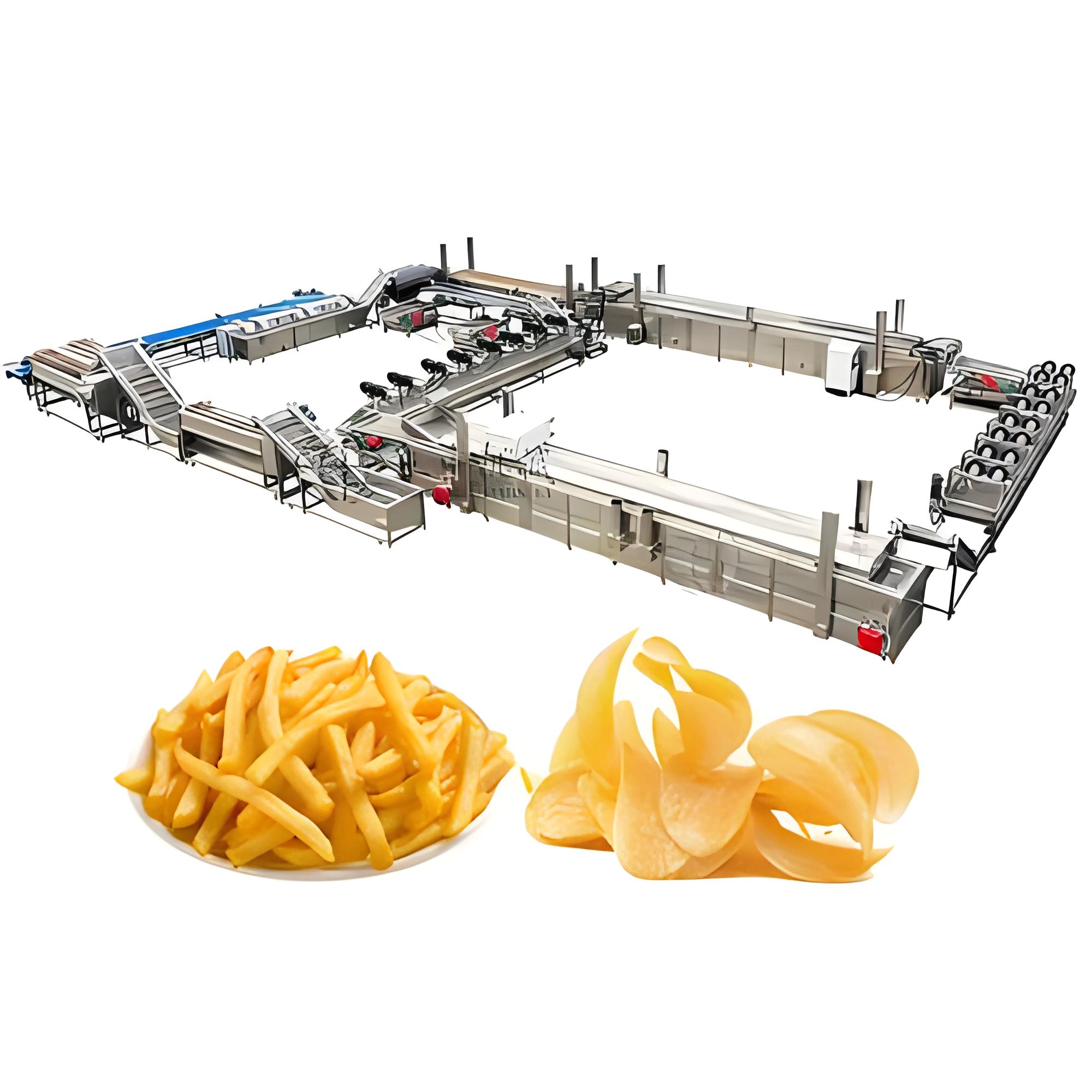

Our Potato Chips Production Line is a turnkey solution designed for snack food manufacturers seeking to automate and scale their production of high-quality potato chips. From raw potato feeding, peeling, slicing, and washing to frying, seasoning, and packaging, the entire process is fully automated, ensuring consistent output, minimal waste, and maximum hygiene.

Engineered for medium to large-scale commercial operations, the line supports capacities ranging from 300 kg/h to over 2,000 kg/h, and is customizable for both classic and flavored chip varieties. With robust stainless-steel construction, energy-efficient frying technology, and advanced oil filtration systems, our line helps you maintain product quality while reducing operational costs.

Key Benefits

🔧 Customizable Layouts for different plant sizes and throughput requirements

🔁 Continuous & Stable Operation with minimal manual intervention

🌡️ Intelligent Frying Control ensures uniform crispness and color

🧼 CIP Cleaning Systems for improved sanitation and compliance with food safety standards

📈 Rapid ROI through reduced labor cost and consistent high-yield production

Whether you're producing traditional salted chips, ridged crisps, or artisanal kettle-cooked varieties, our Potato Chips Line delivers industrial-grade reliability, flexible configuration, and global technical support—empowering your brand to grow in a competitive snack market.

Automatic Potato Chips Production Line

Automatic Potato Chips Production Line Potato Chips Instant Freezer

Potato Chips Instant Freezer Rotary Drum Potato Chips Seasoning Machine

Rotary Drum Potato Chips Seasoning Machine 250kg/Hr Compound Potato Chips Frying Plant

250kg/Hr Compound Potato Chips Frying Plant Compound Potato Chips Baking Line

Compound Potato Chips Baking Line Fully Automatic Potato Chips Line

Fully Automatic Potato Chips Line French Fries Production Line

French Fries Production Line Vegetable Processing Line

Vegetable Processing Line Vacuum Quantitative Filling Machine

Vacuum Quantitative Filling Machine Standard Integrated Weighing and Packaging Machine

Standard Integrated Weighing and Packaging Machine Yogurt Making Machine

Yogurt Making Machine Screw Potato Peeling Washing Machine

Screw Potato Peeling Washing Machine Hydraulic Sausage Filling Machine

Hydraulic Sausage Filling Machine Blackfish Canning Production Line

Blackfish Canning Production Line Semi-automatic Potato Crisps Production Line

Semi-automatic Potato Crisps Production Line