French Fries Production Line Price - Chinese Manufacturer, Factory, Supplier

Understanding the factors that influence the french fries production line price is crucial for any business planning to invest in this segment of the food processing industry. Prices can vary significantly, depending on a range of elements including production capacity, equipment configuration, automation level, material quality, and the reputation of the manufacturer. Buyers should approach this investment with a clear grasp of both operational requirements and long-term business objectives.

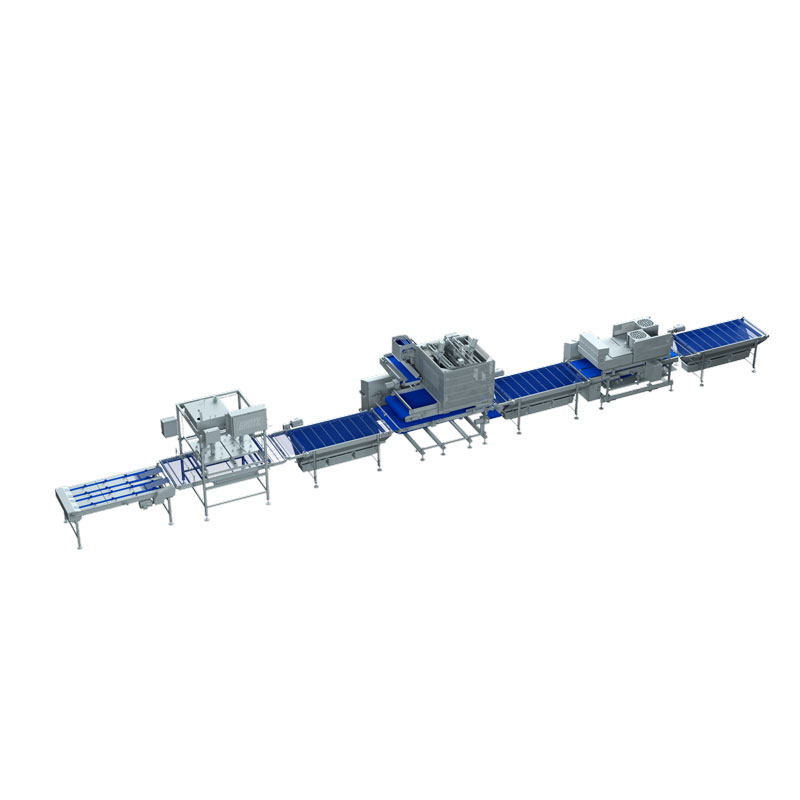

The french fries production line price typically ranges from modest figures for small-scale setups to substantial investments for large, fully automated lines. Entry-level systems, designed for startups or artisanal producers, might begin at $30,000 to $80,000 USD. These compact lines cover the essentials — washing, peeling, slicing, blanching, frying, de-oiling, freezing, and packing — but may require more manual intervention and offer lower throughput.

On the other hand, industrial-scale solutions with higher output capacities, advanced automation, and sophisticated control systems can elevate the french fries production line price to well over $500,000 USD. These systems are engineered for maximum efficiency, incorporating features like intelligent sorting, oil filtration systems, energy recovery technologies, and smart diagnostics. While the upfront cost is higher, the operational efficiencies and output volume typically justify the expenditure for larger manufacturers aiming for global distribution.

Material quality is another decisive factor affecting the french fries production line price. Food-grade stainless steel, precision-engineered components, and durable electronics not only ensure compliance with international hygiene standards but also extend the lifespan of the equipment, offering greater return on investment over time.

Customization plays a pivotal role as well. Tailored solutions to accommodate specific potato varieties, unique cut styles, or particular freezing technologies can significantly impact the final quotation. Buyers looking for flexibility and future scalability should factor these bespoke requirements into their budgeting process.

Geographical sourcing can also influence the french fries production line price. Chinese manufacturers, for example, often provide more competitive pricing while maintaining robust quality standards, making them attractive to businesses seeking value without compromising performance.

Ultimately, understanding the total cost of ownership — including installation, training, maintenance, and energy consumption — offers a clearer picture than initial price alone. A well-chosen french fries production line price reflects not just the cost of equipment, but the potential for streamlined operations, consistent product quality, and profitable growth.

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Tomato Ketchup Processing Line

Tomato Ketchup Processing Line Automatic Sardine Canning Line Equipment

Automatic Sardine Canning Line Equipment  Commercial Stufed Meatball Forming Machine

Commercial Stufed Meatball Forming Machine Full-automatic Meat Smoke Oven

Full-automatic Meat Smoke Oven Fully Automated Pizza Production Line

Fully Automated Pizza Production Line YL-W-02 Commercial Water Purification Equipment

YL-W-02 Commercial Water Purification Equipment