Automated Food Production Lines - Chinese Manufacturer, Factory, Supplier

Modern automated food production lines are transforming the global food processing industry by integrating advanced technology, robotics, and intelligent control systems into every stage of manufacturing. These systems streamline workflows from raw material preparation through cooking, packaging, labeling, and palletizing, ensuring higher efficiency, consistent product quality, and reduced reliance on manual labor.

One of the defining features of automated food production lines is precision. Computer-controlled machinery ensures accurate dosing, portioning, and mixing, which not only improves product uniformity but also reduces waste. High-speed conveyors, automated filling machines, and robotic arms work in harmony to achieve seamless operations. This level of automation enables manufacturers to meet large-scale demand while maintaining compliance with international safety and hygiene standards such as HACCP, ISO, and FDA.

Flexibility is another advantage. Modern systems can be adapted for a wide range of food categories, including canned goods, bakery products, frozen meals, dairy, beverages, snacks, and ready-to-eat foods. Customizable modules allow processors to switch between different recipes or packaging formats quickly, catering to diverse market needs without costly downtime. For example, a single line may handle both canned fish and canned beans, or switch from glass bottles to carton packs with minimal adjustments.

Efficiency is enhanced by real-time monitoring and data collection. Many automated food production lines are equipped with PLC controls, SCADA systems, and IoT sensors that track temperature, pressure, and cycle times. This data-driven approach improves quality control, reduces energy consumption, and supports predictive maintenance, ensuring long-term operational reliability.

Sanitation and food safety are also prioritized. Equipment is typically constructed from food-grade stainless steel with hygienic design principles that allow easy cleaning and minimize contamination risks. Automated washing systems, sterilization units, and strict environmental controls maintain compliance with global food safety regulations.

Investing in automated systems offers a strong return on investment. While the initial cost may be significant, benefits such as reduced labor expenses, minimized product losses, consistent throughput, and longer shelf life contribute to long-term profitability. Moreover, automation helps address labor shortages and rising wage costs in many regions, providing businesses with sustainable growth opportunities.

Trusted suppliers, including those in China and Europe, now export turnkey automated food production lines worldwide. They provide comprehensive support, from system design and installation to operator training and after-sales service. By adopting these technologies, food manufacturers can remain competitive in rapidly evolving markets, ensuring efficiency, scalability, and consumer confidence.

Types of Automated Food Production Lines & Applications

| Category | Typical Equipment | Main Applications | End Products |

|---|---|---|---|

| Canning Production Lines | Can seaming machines, sterilizers, filling machines, labeling machines | Meat, fish, fruit, vegetable, sauce canning | Canned tuna, sardine, tomato paste, fruit cocktail |

| Frozen Food Production Lines | IQF tunnel freezers, glazing machines, packaging machines, cutting & portioning equipment | Meat, seafood, dumplings, vegetables | Frozen shrimp, frozen dumplings, frozen peas |

| Beverage Production Lines | Blending tanks, pasteurizers, filling machines, PET/Glass bottle conveyors | Soft drinks, juices, dairy drinks, alcoholic beverages | Juice bottles, beer cans, milk cartons |

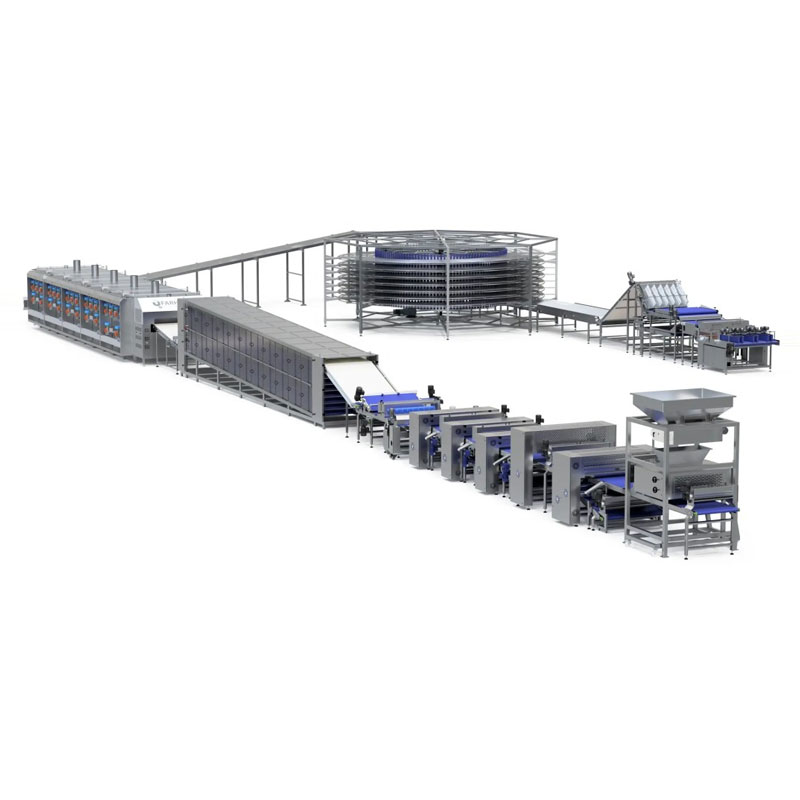

| Bakery & Confectionery Production Lines | Dough mixers, proofers, ovens, cooling conveyors, enrobing machines | Bread, cakes, biscuits, candy, chocolate | Sandwich bread, cookies, chocolate bars |

| Sauce & Condiment Production Lines | Mixing tanks, colloid mills, sterilization kettles, filling equipment | Ketchup, chili sauce, soy sauce, mayonnaise | Packaged tomato ketchup, chili paste, soy sauce bottles |

| Snack Food Production Lines | Fryers, extruders, flavoring drums, packaging machines | Potato chips, extruded snacks, popcorn | Potato crisps, puffed corn snacks, flavored popcorn |

| Dairy Processing Lines | Pasteurizers, homogenizers, fermenters, aseptic filling machines | Milk, yogurt, cheese, butter | Packaged yogurt, UHT milk, sliced cheese |

| Meat & Poultry Processing Lines | Slaughtering lines, deboning machines, portion cutters, vacuum packaging machines | Beef, pork, chicken, sausages | Packaged fresh meat, ham, sausages |

| Fruit & Vegetable Processing Lines | Washing machines, peeling machines, cutting machines, drying equipment | Fresh-cut vegetables, dried fruit, juices | Packaged salad, dried mango, apple juice |

| Ready-to-Eat Meal Production Lines | Cooking kettles, tray sealers, retort sterilizers, packaging conveyors | Microwave meals, soups, curry packs | Frozen lasagna, canned soup, curry pouches |

Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Eel Canned Food Production Line

Eel Canned Food Production Line Dairy Lines

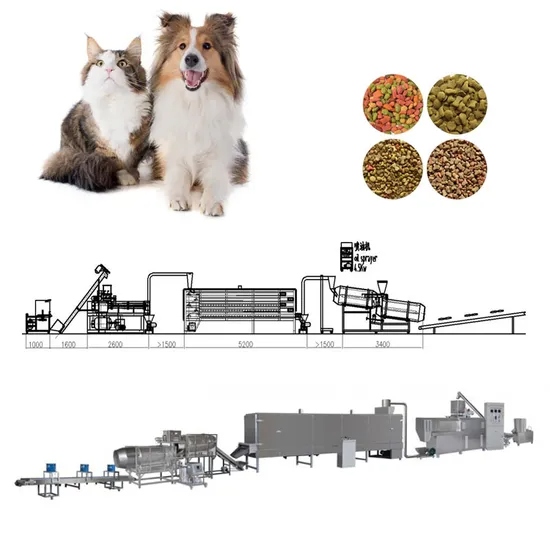

Dairy Lines Dry Pet Food Production Line

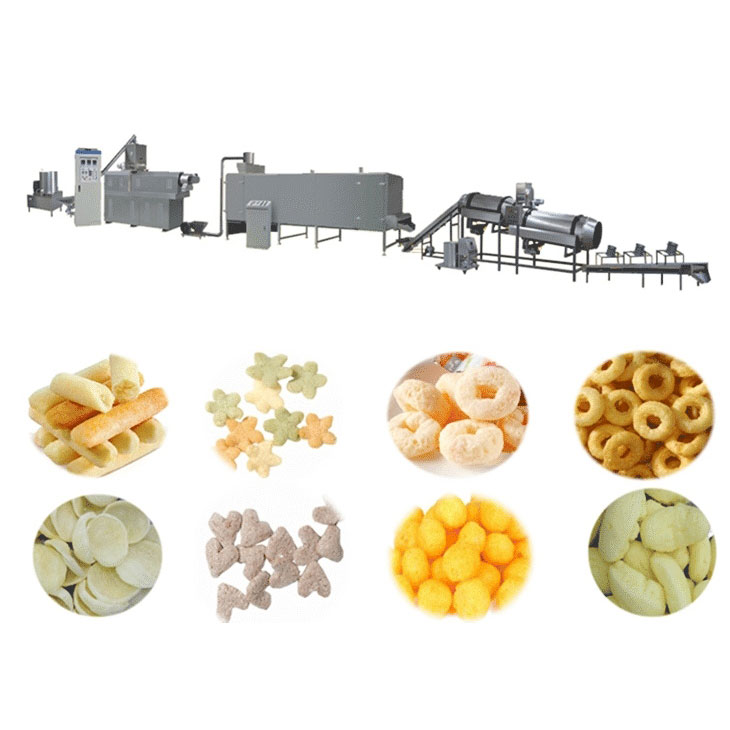

Dry Pet Food Production Line Snack Production Line

Snack Production Line SY-168 / SY-158 Commercial Ice Shaver Machine

SY-168 / SY-158 Commercial Ice Shaver Machine Vegetable Processing Line

Vegetable Processing Line Pita Production Line

Pita Production Line Fried Food Deoiling Machine

Fried Food Deoiling Machine Chicken Processing Line

Chicken Processing Line Meat Shredding Machine

Meat Shredding Machine Automatic Fresh Meat Dicing Machine

Automatic Fresh Meat Dicing Machine Membrane Skinner

Membrane Skinner