Tortilla Production Line - Chinese Manufacturer, Factory, Supplier

Commercial tortilla manufacturing requires specialized tortilla production line equipment that preserves authentic texture while achieving industrial-scale output. These automated systems blend traditional masa preparation techniques with modern processing technology to deliver consistent products that meet growing market demand for Mexican flatbreads.

Masa preparation initiates every tortilla production line through controlled hydration of nixtamalized corn flour or wheat flour blends. Industrial mixers incorporate precise water-to-flour ratios while maintaining optimal dough temperature through jacketed mixing bowls and temperature monitoring systems. Dough consistency directly impacts final tortilla flexibility and shelf stability.

Dividing mechanisms portion masa into uniform weights through volumetric or gravimetric systems. Rotary dividers create consistent portions that feed into pressing stations where hydraulic or pneumatic presses flatten dough balls into circular discs. Press pressure, dwell time, and plate temperature require precise calibration to achieve proper thickness without compromising dough structure.

Modern tortilla production line configurations feature continuous pressing systems that utilize heated platens to simultaneously flatten and pre-cook tortillas during forming operations. These dual-function presses reduce processing time while improving product uniformity through controlled heat application during shaping phases.

Baking occurs within specialized ovens designed for flatbread production. Gas-fired or electric heating systems maintain precise temperature profiles while conveyor belts transport tortillas through multiple heating zones. Residence time and temperature gradients determine moisture content, color development, and textural characteristics essential for quality tortillas.

Cooling systems within tortilla production line installations prevent moisture condensation through controlled air circulation and temperature reduction protocols. Spiral cooling conveyors maximize cooling efficiency while minimizing floor space requirements in production facilities.

Quality control measures include optical inspection systems that identify defective tortillas based on diameter, thickness, color uniformity, and surface irregularities. Automated rejection systems remove substandard products without interrupting continuous production flow.

Stacking and packaging operations complete the tortilla production line sequence through automated counting systems and protective packaging materials. Counter-stackers create uniform product stacks while maintaining tortilla integrity during handling operations. Packaging machinery applies moisture-barrier films that extend shelf life while preserving product freshness.

Advanced tortilla production line systems achieve production rates exceeding 4,000 tortillas per hour while maintaining traditional taste profiles and textural characteristics. These installations incorporate sanitary design principles, automated cleaning systems, and process control technologies that ensure consistent product quality while meeting strict food safety regulations governing commercial food production facilities.

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Meat Stuffer Machine

Meat Stuffer Machine Automatic Can Sealing Machine

Automatic Can Sealing Machine Tofu Production Line

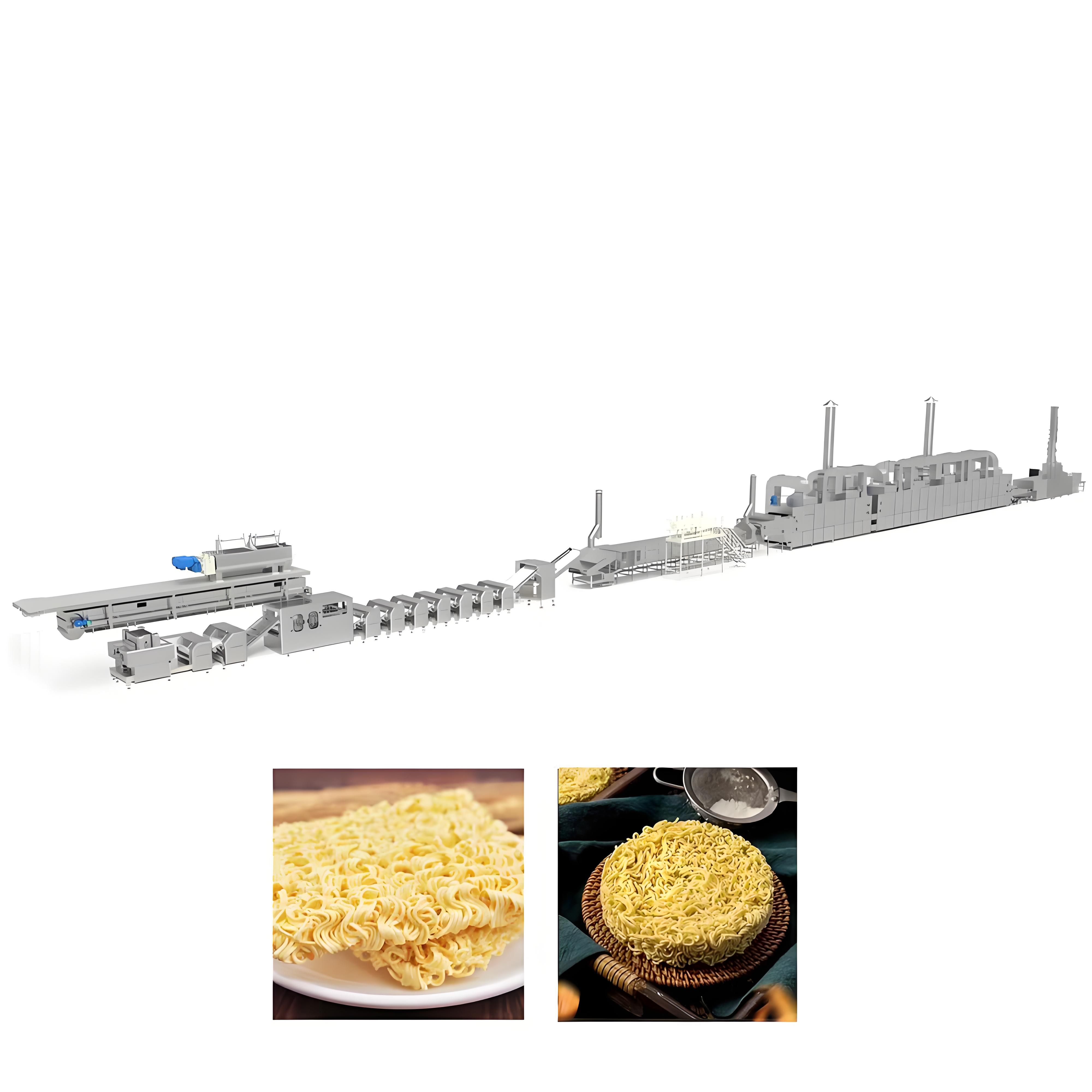

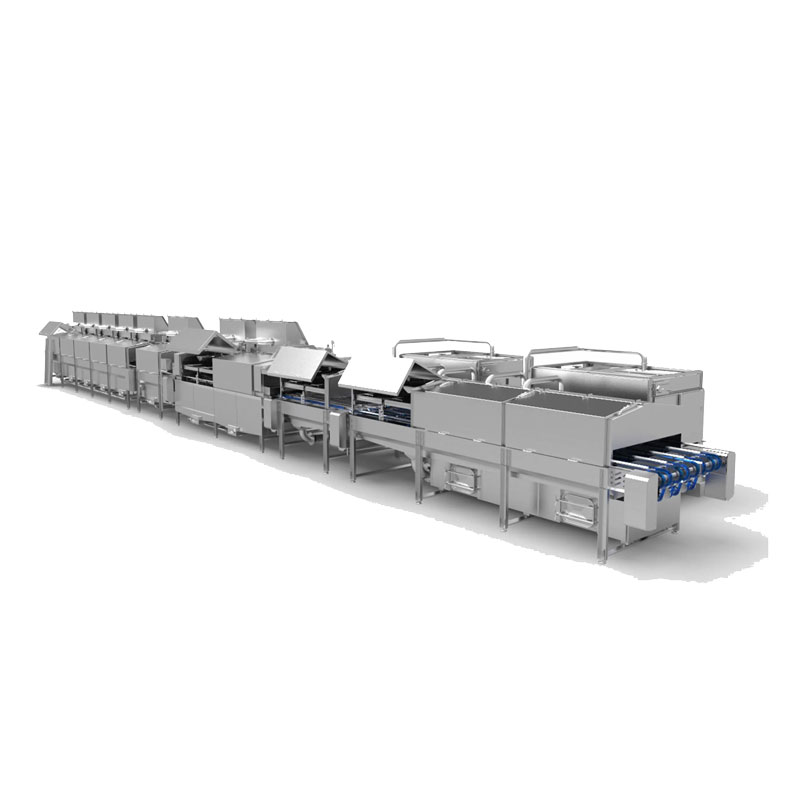

Tofu Production Line Deep-Fried Instant Noodle Production Line

Deep-Fried Instant Noodle Production Line Shrimp Processing Line

Shrimp Processing Line Pelmeni Making Machine

Pelmeni Making Machine Chicken Processing Line

Chicken Processing Line SD Square Ice Series Upright Ice Makers

SD Square Ice Series Upright Ice Makers