Overview

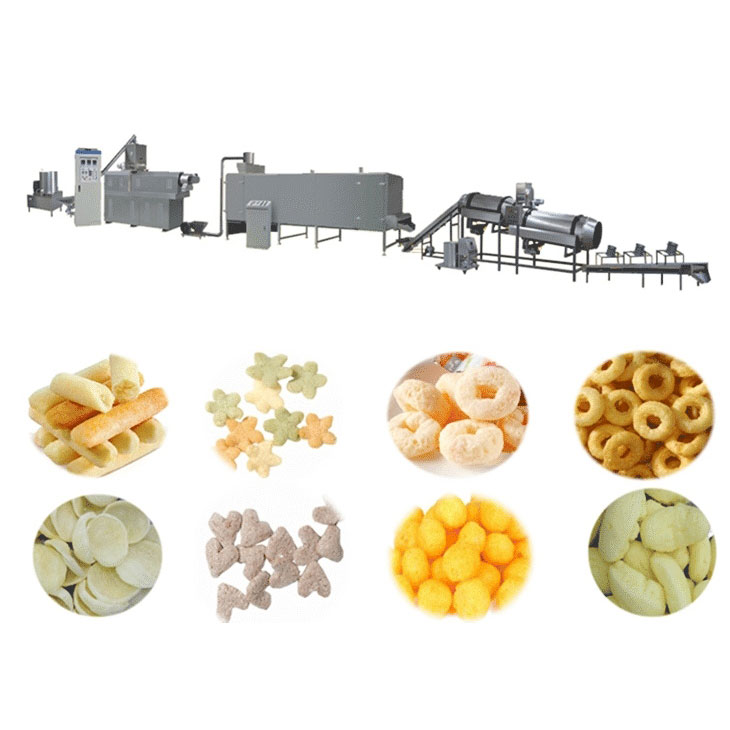

The Snack Production Line is a complete automated system designed for manufacturing a wide variety of puffed, fried, or baked snacks — including potato chips, corn puffs, extruded snacks, and coated nuts.

It integrates all stages from raw material preparation to packaging, ensuring high efficiency, consistent quality, and hygiene compliance for both small and large-scale snack factories.

Whether for a new production plant or upgrading existing equipment, this line offers modular configurations that can be tailored to your production capacity, recipe, and process technology.

⚙️ Main Features

✅ Full Process Integration

From raw material feeding, mixing, extrusion, frying/baking, seasoning, to packaging — all processes are seamlessly connected for continuous operation.

✅ Flexible Snack Type Production

Suitable for potato chips, corn curls, cheese balls, rice crackers, bugles, coated peanuts, and other puffed or fried snacks.

By adjusting the extruder die, seasoning system, or fryer, you can produce multiple types of snacks on one line.

✅ Hygienic and Durable Design

All contact parts are made of SUS304 stainless steel. The structure is easy to clean and designed according to HACCP and CE standards, ensuring food safety and long-term durability.

✅ Energy-Efficient Heating System

Equipped with electric, gas, or diesel heating options. The insulation system minimizes energy loss while maintaining stable temperature control during frying or baking.

✅ Smart Control & Automation

PLC touchscreen control panel allows real-time monitoring of temperature, speed, and oil level. Recipe memory and fault alarm features make operation simple and reliable.

✅ Consistent Product Quality

Advanced material feeding, precise frying time control, and uniform seasoning guarantee stable taste, texture, and appearance of the final product.

🧩 Processing Flow

Raw Material Preparation

Mixer / feeder for corn flour, potato starch, or rice flour

Continuous feeding system for stable extrusion

Extrusion or Cutting Section

Twin-screw extruder or cutting machine shapes the product

Adjustable mold system for various snack shapes

Frying / Baking Section

Continuous fryer or hot-air baking oven

Temperature control and oil filtration system

Seasoning System

Flavoring drum with powder and oil spraying unit

Uniform flavor coating and minimal waste

Cooling & Conveying

Air-cooling conveyor ensures crisp texture

Stainless-steel conveyors with adjustable speed

Weighing & Packaging

Multihead weigher and vertical form-fill-seal (VFFS) packaging machine

Optional nitrogen flushing for extended shelf life

📊 Technical Parameters

| Model | Capacity | Power | Heating Type | Material | Dimension (L×W×H) |

|---|---|---|---|---|---|

| SL-100 | 100–200 kg/h | 35 kW | Electric / Gas | SUS304 | 15×2×3 m |

| SL-300 | 300–500 kg/h | 55 kW | Gas / Diesel | SUS304 | 25×3×3.5 m |

| SL-500 | 600–1000 kg/h | 80 kW | Gas / Steam | SUS304 | 30×4×4 m |

| SL-1000 | 1000–1500 kg/h | 120 kW | Custom | SUS316 | Customized |

Capacity and heating method can be customized based on product type and local energy source.

🧠 Optional Equipment

Oil filtration & recycling system

Flavor dosing unit

Nitrogen flushing packaging machine

Automatic cleaning (CIP) system

Energy-saving heat recovery system

🌍 Applications

Snack food manufacturing plants

Potato & corn processing factories

Contract food production centers

Industrial catering and food distribution enterprises

💡 Advantages

Stable product quality with high yield

Easy operation and low maintenance

Suitable for multiple snack types

Energy-efficient and eco-friendly

Support for full turnkey project setup

🔧 Turnkey Project Support

We offer complete turnkey engineering, including:

Factory layout design and technical consultation

Installation, testing, and operator training

Process customization based on local recipes

Spare parts supply and long-term maintenance service

Must-read blogs for bosses