Manual Tomato Sauce Machine - Chinese Manufacturer, Factory, Supplier

The Manual Tomato Sauce Machine is a compact and efficient solution designed for small-scale food processors, restaurants, catering services, and farms looking to process fresh tomatoes into high-quality sauce, puree, or paste. Unlike large automated production lines, this manual machine emphasizes simplicity, cost-effectiveness, and flexibility, making it an ideal choice for businesses with lower production volumes or artisanal food production.

Key Features:

Durable Construction: Built from stainless steel or food-grade cast materials, ensuring hygiene, easy cleaning, and long service life.

Hand-Operated Mechanism: Designed with a robust crank handle that allows easy processing of tomatoes without electricity, reducing operating costs.

Versatility: Suitable for processing tomatoes into sauce, puree, or juice. It can also be adapted for other soft fruits such as berries or cooked vegetables.

Compact & Portable: Lightweight design, requiring minimal space, ideal for kitchens, small workshops, or farms.

Easy Assembly & Maintenance: Simple design with detachable parts for quick cleaning and reassembly.

Applications:

Small Food Processors & Startups: Perfect for local sauce brands or artisanal food producers.

Restaurants & Catering: On-demand preparation of fresh tomato sauces.

Farmers & Growers: Add value to fresh tomato harvests through direct sauce production.

Developing Regions: Reliable solution where electricity or industrial equipment may not be accessible.

Advantages:

Low initial investment with high ROI for small-scale operations.

Eco-friendly and energy-saving with manual operation.

Provides full control over production quality and batch size.

Small Scale Tomato Sauce Making Machine

Small Scale Tomato Sauce Making Machine Tomato Sauce Milling Machine

Tomato Sauce Milling Machine Tomato Sauce Grinding Machine

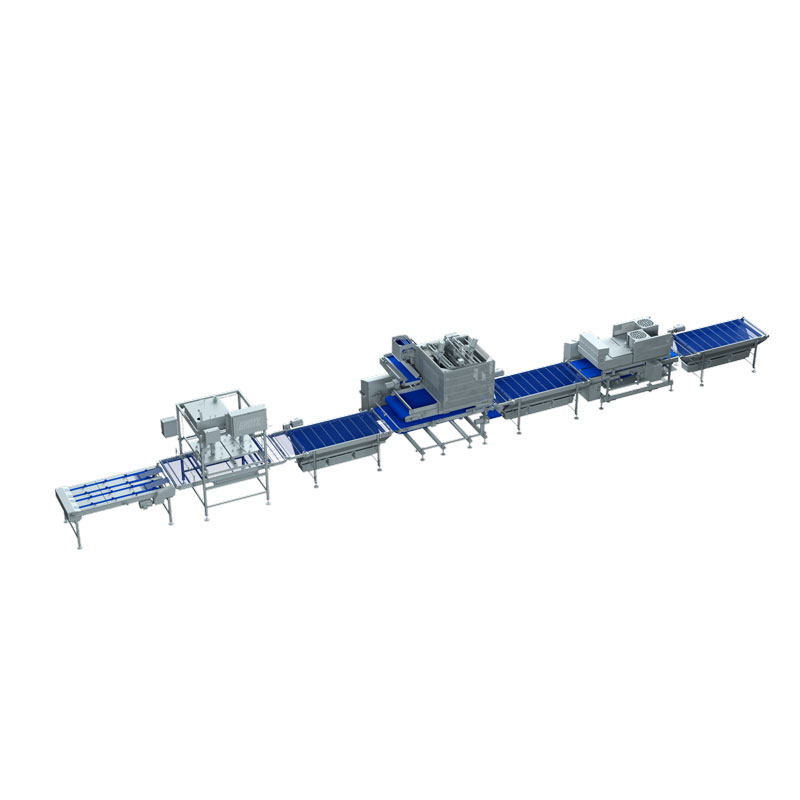

Tomato Sauce Grinding Machine Tomato Juice Processing Production Line

Tomato Juice Processing Production Line Sauce Filling Machine

Sauce Filling Machine Tomato Sauce Machine

Tomato Sauce Machine Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine Tomato Ketchup Processing Line

Tomato Ketchup Processing Line Tomato Paste Production Line

Tomato Paste Production Line Mayonnaise Production Line

Mayonnaise Production Line Fish Scaler Machine

Fish Scaler Machine Bone Crusher Machine

Bone Crusher Machine Automatic Sausage Peeling Machine

Automatic Sausage Peeling Machine Sausage Stuffer Machine

Sausage Stuffer Machine Fully Automated Pizza Production Line

Fully Automated Pizza Production Line Meat Canned Food Production Line

Meat Canned Food Production Line YL-W-01 Commercial Water Purification Equipment

YL-W-01 Commercial Water Purification Equipment