155g Semi-Automatic Fish Canning Production Line - Chinese Manufacturer, Factory, Supplier

Meeting market demand for high-quality canned seafood requires equipment that balances efficiency, precision, and cost-effectiveness. The 155g Semi-Automatic Fish Canning Production Line is designed to provide seafood processors with a versatile solution that bridges manual operations and full automation, making it ideal for medium-scale production facilities.

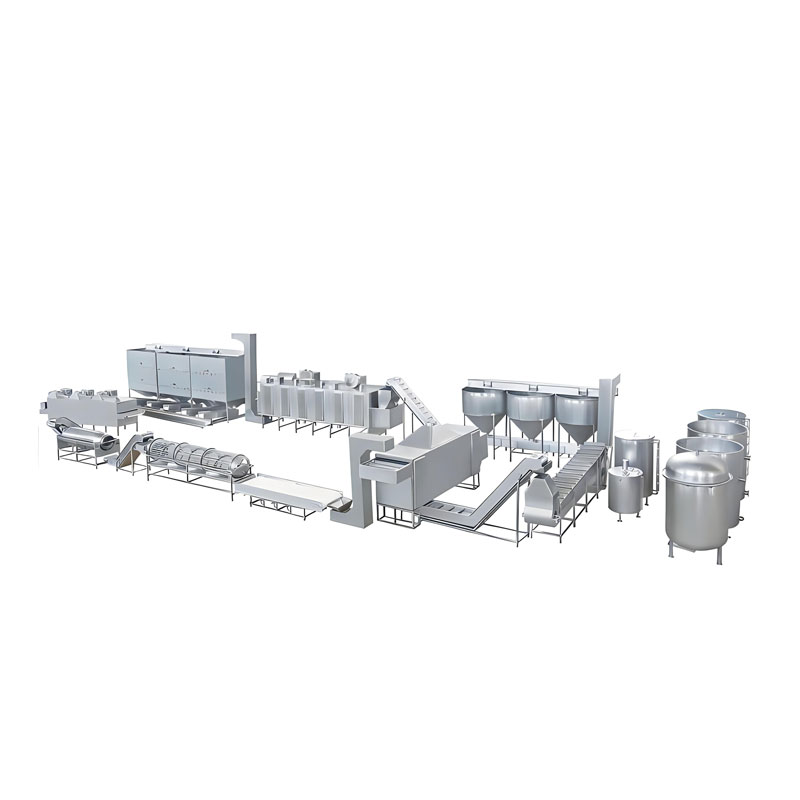

This production line integrates essential processes, including fish cleaning, cutting, pre-cooking, filling, sealing, sterilization, and labeling. While certain tasks remain manually guided, key stages such as filling and sealing are mechanized to ensure consistent weight and airtight packaging. By producing uniform 155-gram portions, the system minimizes product variation and enhances consumer trust through precise quality control.

Constructed with robust, food-grade stainless steel, the equipment is engineered for durability and compliance with international hygiene standards. Its semi-automatic design allows for flexible production, accommodating different fish species and packaging requirements. Moreover, it provides a practical upgrade path for processors seeking to gradually transition toward full automation without a large upfront investment.

Working with an experienced china manufacturer brings additional benefits, including cost-efficient production solutions, custom configuration options, and dependable after-sales support. These manufacturers often offer technical training, on-site installation, and readily available spare parts, ensuring long-term operational stability.

As global seafood markets grow more competitive, processors must balance output speed with quality assurance. The 155g Semi-Automatic Fish Canning Production Line empowers businesses to increase capacity, reduce labor costs, and maintain strict food safety compliance. By combining semi-automated precision with human oversight, it delivers a reliable, scalable solution for companies aiming to expand their presence in the canned fish industry.

Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Eel Canned Food Production Line

Eel Canned Food Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line AM Series Crescent Ice Maker

AM Series Crescent Ice Maker Cooked Meat Shredder Machine

Cooked Meat Shredder Machine Kimchi Production Line

Kimchi Production Line Meat Tenderizer

Meat Tenderizer Quantitative Vacuum Sausage Filler

Quantitative Vacuum Sausage Filler Multifunction Pasta Machine

Multifunction Pasta Machine Tomato Sauce Milling Machine

Tomato Sauce Milling Machine