Home >

Related Products

Core Competitive Advantages

Technical Leadership & Customer Value Creation Capabilities

Technology Leadership

· 57 core patents in dynamic cutting algorithms & IoT control

· 8.5% R&D investment ratio with 3-5 new models annually

Agile Supply Chain

· 82% vertical integration of critical components

· 40% inventory turnover improvement via digital systems

Full-Lifecycle Service

· 25% lower TCO for equipment lifecycle

· 24/7 remote diagnostics support

· >95% client retention over 5 years

Green Compliance

· 35% energy consumption reduction

· Certified by CE/FDA/ISO 14064

· ≥92% material recyclability

Project Case

Learn about our efficient and reliable equipment and production line solutions tailored for various food processing industries.

Commercial Kitchen Equipment

Snack Food Processing Equipment

Fruit and Vegetable Processing Equipment

Meat Processing Equipment

Bakery & Cereal Processing Equipment

Seafood Processing Equipment

Dairy Processing Equipment

Seasoning & Sauce Processing Equipment

Cosmetics Processing Equipment

Pet Food Processing Equipment

Ready Meal Processing Equipment

Beer and Beverage Processing Equipment

Relevant News

How Much Does a Luncheon Meat Canning Production Line Cost?

1. Introduction: Why Luncheon Meat Canning Lines Are in High DemandThe global demand for luncheon meat has been steadily increasing thanks to modern consumers’ ...

How Much Does a Meat Canning Production Line Cost?

1. Introduction: The Growing Market for Canned MeatThe global canned meat industry has been growing rapidly due to rising demand for ready-to-eat protein produc...

How Much Does A Fully Automatic Canning Production Line Cost Per Unit?

Canning production lines are a cornerstone for modern food processing factories, enabling manufacturers to produce shelf-stable products efficiently and consist...

How Much Does A Fruit Canning Production Line Cost?

In today’s fast-changing food industry, fruit canning production lines have become an essential investment for manufacturers looking to preserve seasonal fruits...

Choose the Right Dicing Machine and Save Time & Money: A Tailored Procurement Guide for Your Bus

Why Choosing the Right Dicing Machine Matters for Your BusinessIn the food processing industry—whether it's fruit and vegetable pre-processing, meat handlin...

Automatic Chicken Cutting Machine Price: A Comprehensive Guide to Understanding Costs and Value

IntroductionIn today’s fast-paced food production environment, efficiency is everything. The automatic chicken cutting machine stands at the heart of this trans...

How to Find the Best Sauce Packing Machine

Introduction: Understanding Sauce Packing Machine PricingThe packaging process is essential in the food industry, and when it comes to sauces, the right packing...

How to Find the Right Sauce Packing Machine Price

Introduction to Sauce Packing Machine PriceWhen it comes to streamlining the production of sauces, choosing the right packing machine is a key consideration for...

Sauce Making Machine Price: A Comprehensive Guide to Costs, Factors, and Value

Introduction: Why Understanding Sauce Making Machine Prices is Crucial for Your BusinessThe significance of a sauce making machine in the food industryIn the fo...

How Much Should You Pay for a Bone Meat Cutter Machine? A Complete Price Breakdown

In the world of meat processing, the right equipment can make a significant difference in efficiency and product quality. One such essential tool is the bone me...

What Are the Cost Considerations When Purchasing a Meat Slicer?

I still vividly remember my first encounter with a professional meat slicer in m

Chicken Cutting Machine Price: A Comprehensive Guide to Finding the Best Value

The chicken cutting machine has become an indispensable tool in the food process

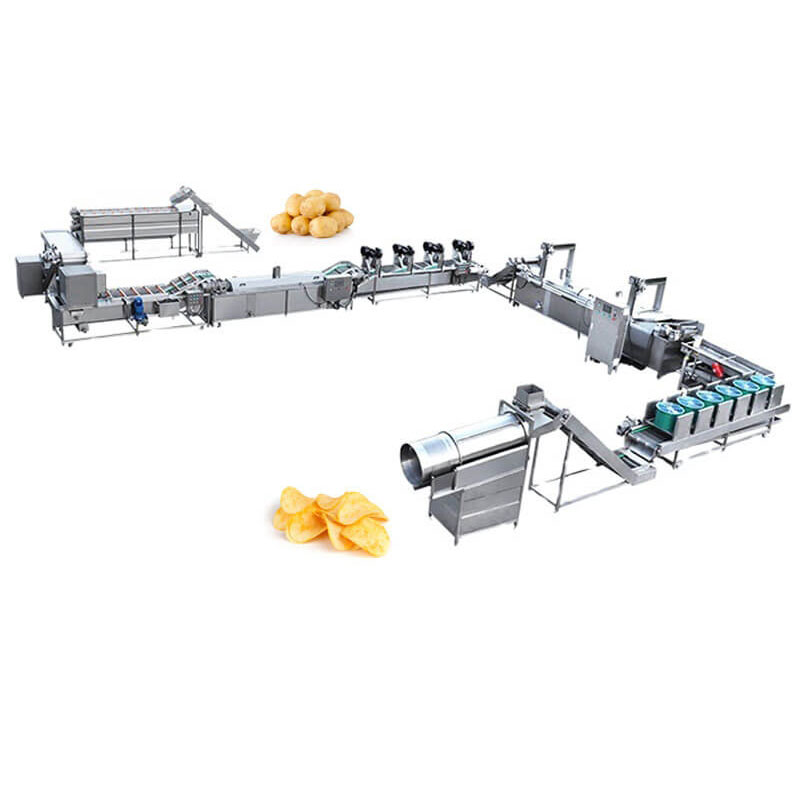

Potato Processing Line

Potato Processing Line Potato Chip Line

Potato Chip Line Automatic Potato Chips Production Line

Automatic Potato Chips Production Line Twist Potato Machine

Twist Potato Machine Potato Washing&Peeling Machine

Potato Washing&Peeling Machine Potato Chips Instant Freezer

Potato Chips Instant Freezer Rotary Drum Potato Chips Seasoning Machine

Rotary Drum Potato Chips Seasoning Machine Brush Potato Washing Peeling Machine

Brush Potato Washing Peeling Machine Screw Potato Peeling Washing Machine

Screw Potato Peeling Washing Machine 250kg/Hr Compound Potato Chips Frying Plant

250kg/Hr Compound Potato Chips Frying Plant Compound Potato Chips Baking Line

Compound Potato Chips Baking Line Semi-automatic Potato Crisps Production Line

Semi-automatic Potato Crisps Production Line Microwave Pigskin Puffing Machine

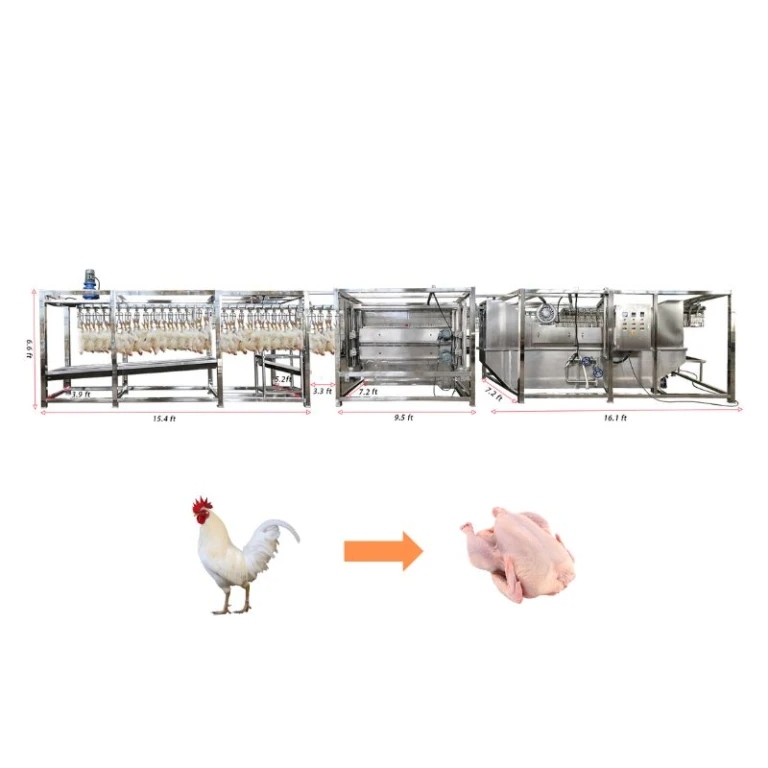

Microwave Pigskin Puffing Machine Chicken Production Line

Chicken Production Line Pancake Production Line

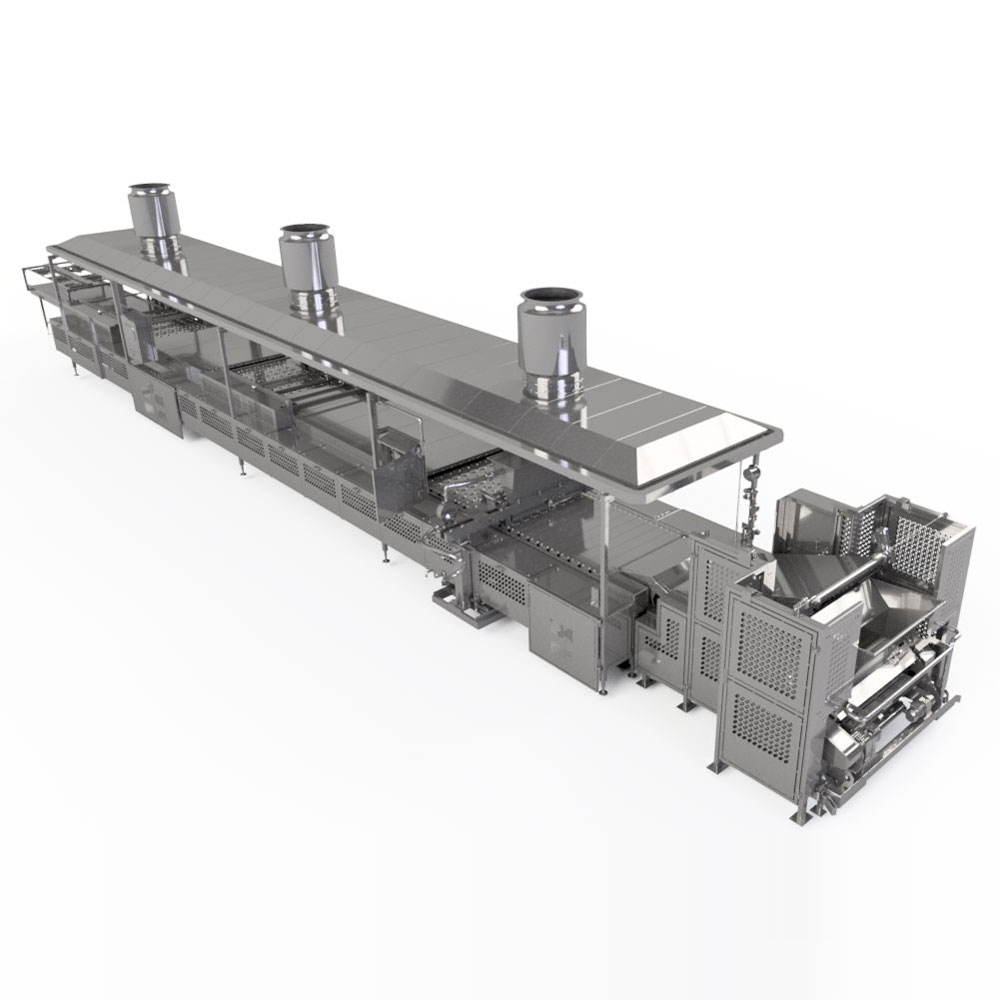

Pancake Production Line French Fries Frying Machine

French Fries Frying Machine Honey Processing Equipment

Honey Processing Equipment Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine AF Series Flake Pellet Ice Machine

AF Series Flake Pellet Ice Machine