Commercial Automatic Pasta Machine - Chinese Manufacturer, Factory, Supplier

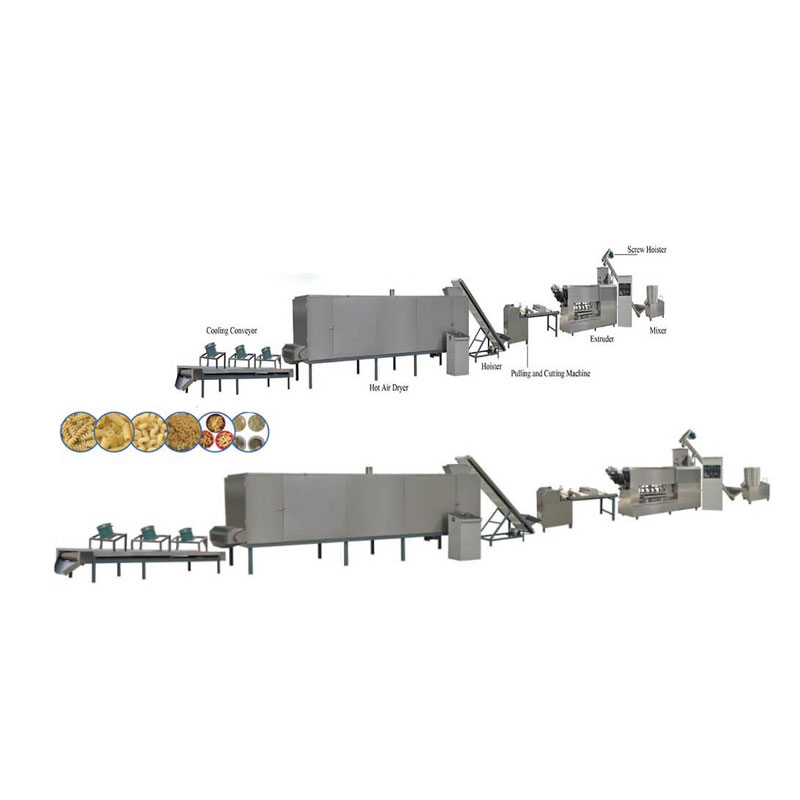

A commercial automatic pasta machine is a game-changing solution for food businesses seeking efficiency, consistency, and high-quality pasta production. Unlike traditional manual equipment, these machines integrate advanced automation systems that streamline every stage of the process—from dough preparation to shaping, cutting, drying, and even packaging—delivering a seamless workflow that minimizes labor costs while maximizing output.

The core advantage of a commercial automatic pasta machine lies in its precision. Equipped with powerful motors, programmable controls, and interchangeable dies, it can produce a wide variety of pasta types, including spaghetti, macaroni, penne, fusilli, and lasagna sheets. This versatility allows food businesses to respond quickly to market trends and consumer preferences, while ensuring consistent texture and cooking performance across every batch.

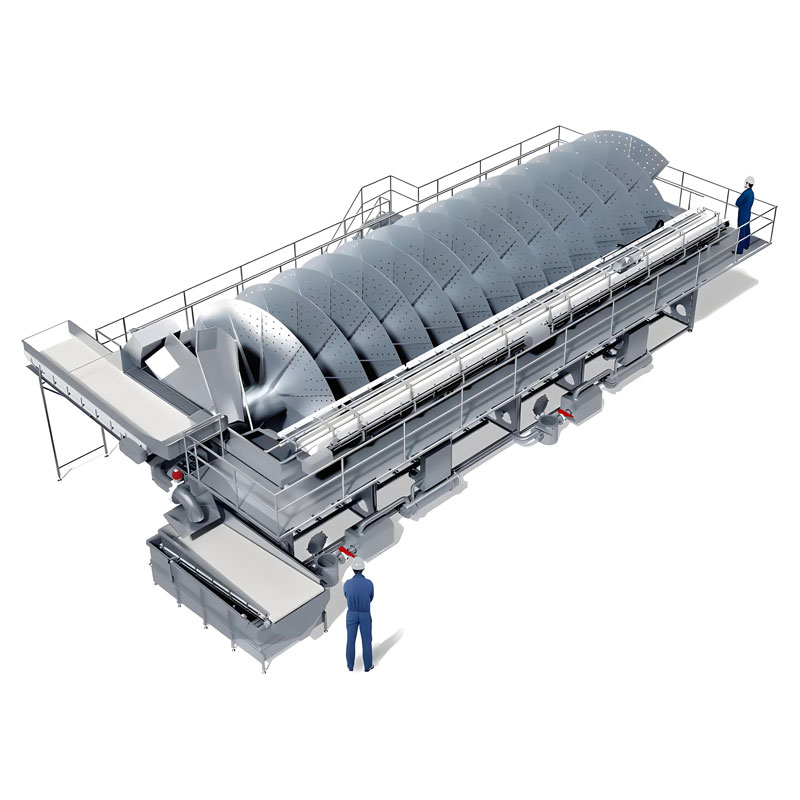

Durability and hygiene are central to the design of these machines. Most models are built with food-grade stainless steel, resistant to corrosion and easy to sanitize. Smooth surfaces, detachable parts, and automated cleaning functions reduce downtime and support compliance with HACCP, ISO, and GMP standards. With strict quality controls, businesses can guarantee that every pasta product meets international food safety requirements.

For commercial operations, efficiency is critical. A commercial automatic pasta machine is capable of processing hundreds of kilograms of pasta per hour, making it ideal for restaurants, catering companies, and industrial food factories. Energy-efficient designs, automated dough feeding systems, and integrated drying technology not only save time but also lower operational costs.

Customization is another benefit. Manufacturers offer machines with varying capacities, levels of automation, and specialized attachments to suit different production needs. From compact models for small businesses to large-scale production lines for global food companies, the flexibility ensures scalability as demand grows. Some models even include intelligent control panels, allowing operators to adjust recipes, shapes, and drying cycles with ease.

Beyond the machinery itself, many suppliers provide comprehensive support, including installation guidance, operator training, spare parts, and long-term technical service. This guarantees that businesses can maintain smooth operations with minimal interruptions, achieving both productivity and profitability.

In essence, investing in a commercial automatic pasta machine is not just about upgrading equipment—it is about future-proofing pasta production. With higher output, consistent quality, and lower labor reliance, these machines empower businesses to compete effectively in a dynamic global food market while delivering authentic, delicious pasta to customers around the world.

Commercial Dry Pasta Machine

Commercial Dry Pasta Machine Commercial Pasta Extruder

Commercial Pasta Extruder Commercial Pasta Sheeter

Commercial Pasta Sheeter Pasta Production Line

Pasta Production Line Pasta Machine

Pasta Machine Pasta /Macaroni Making Line

Pasta /Macaroni Making Line Multifunction Pasta Machine

Multifunction Pasta Machine AF Series Flake Pellet Ice Machine

AF Series Flake Pellet Ice Machine Meat Smoking Machine

Meat Smoking Machine Salmon Processing Line

Salmon Processing Line Double-Door Sterilizer

Double-Door Sterilizer Frozen Meat Cutting Machine

Frozen Meat Cutting Machine Gizzard Defatter

Gizzard Defatter Fish Cutting Machine

Fish Cutting Machine Stuffed Meatball Machine

Stuffed Meatball Machine