Commercial Pasta Making Machine - Chinese Manufacturer, Factory, Supplier

A commercial pasta making machine is an essential piece of equipment for food manufacturers, restaurants, and central kitchens aiming to produce pasta products at scale with consistent quality. Designed for efficiency and durability, these machines streamline every stage of pasta production, from dough mixing and extrusion to cutting, drying, and packaging, while maintaining authentic taste and texture.

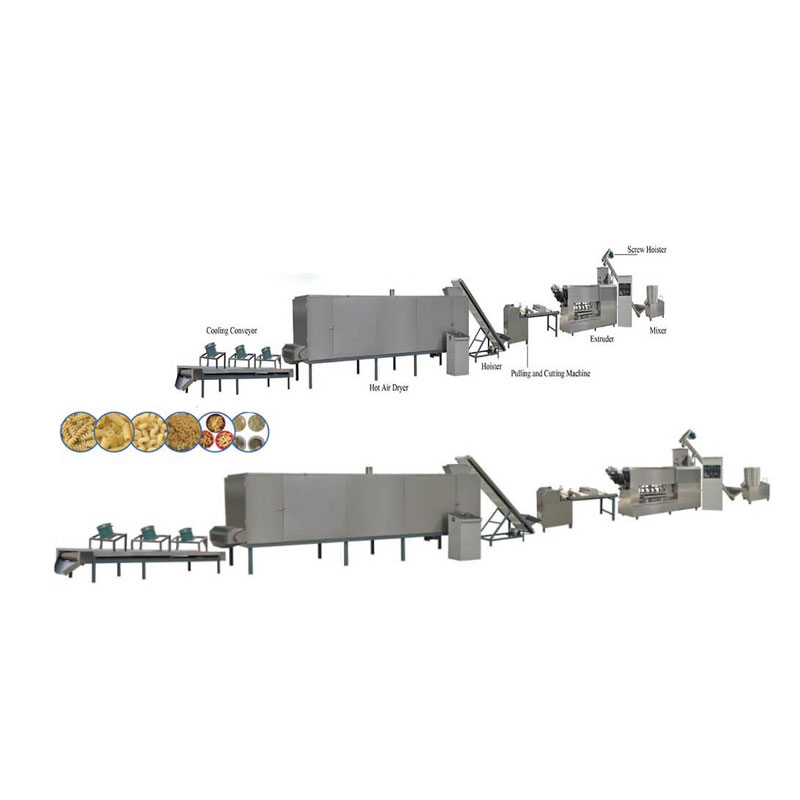

The process begins with automatic dough preparation systems, which combine semolina flour, water, and optional ingredients with precision dosing controls. This ensures uniform hydration and gluten development, the foundation of high-quality pasta. Next, the dough passes into extrusion chambers, where it is pressed through interchangeable dies to create a wide variety of shapes—spaghetti, penne, fusilli, lasagna sheets, and more. By simply changing the mold, manufacturers can diversify their product range without additional equipment investment.

A commercial pasta making machine is engineered to manage continuous high-volume output. Stainless steel construction, food-grade components, and advanced temperature controls ensure hygiene, safety, and durability. Cooling systems and vacuum mixing technologies are often integrated to enhance dough texture and prevent oxidation, resulting in superior color and taste retention.

Downstream equipment such as cutting, drying, and pasteurization units further refine the process. Cutting machines provide uniform portion sizes, while controlled drying tunnels stabilize moisture content for longer shelf life. For fresh pasta lines, pasteurization systems safeguard against microbial contamination without compromising texture. Automated conveyors seamlessly connect each stage, reducing manual labor and boosting production efficiency.

One of the major strengths of a commercial pasta making machine lies in its flexibility. It can be customized for small-scale artisan workshops or fully automated industrial plants. Packaging options—ranging from vacuum packs for fresh pasta to polypropylene bags for dried products—integrate easily, ensuring ready-to-market solutions.

In addition to efficiency, the machines support compliance with global food safety standards such as HACCP, GMP, and ISO certifications. User-friendly interfaces, PLC control systems, and programmable recipes make operation simple while allowing precise adjustments for different pasta types.

Investing in a commercial pasta making machine brings multiple benefits: reduced production costs, higher product consistency, increased throughput, and the ability to respond to changing consumer trends in global pasta markets. For food businesses aiming to scale operations and maintain a competitive edge, this equipment is not just a production tool but a strategic investment in long-term growth.

Commercial Dry Pasta Machine

Commercial Dry Pasta Machine Commercial Pasta Extruder

Commercial Pasta Extruder Commercial Pasta Sheeter

Commercial Pasta Sheeter Pasta Production Line

Pasta Production Line Pasta Machine

Pasta Machine Pasta /Macaroni Making Line

Pasta /Macaroni Making Line Multifunction Pasta Machine

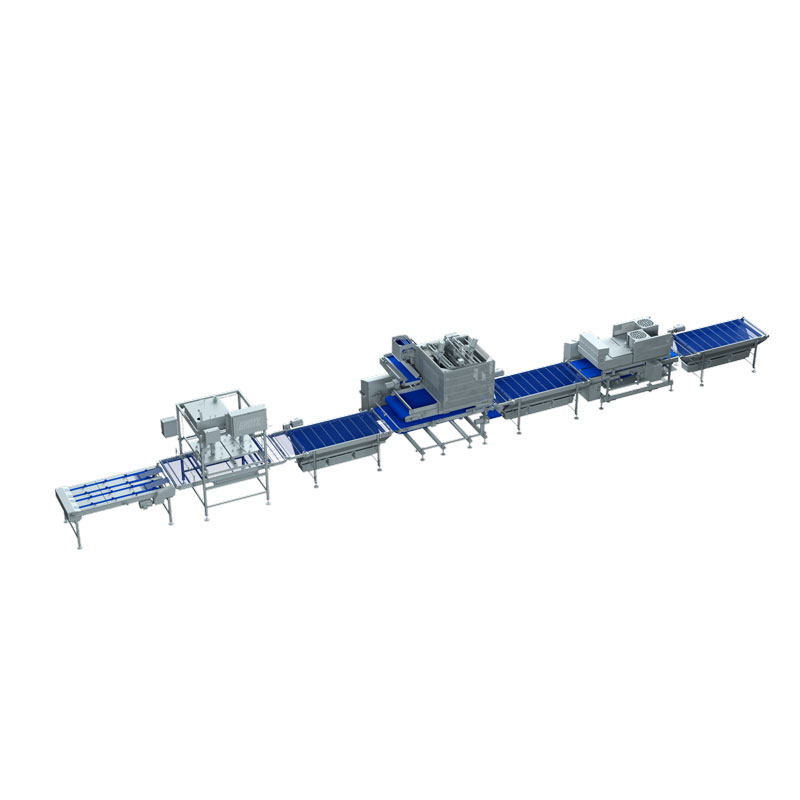

Multifunction Pasta Machine Fully Automated Pizza Production Line

Fully Automated Pizza Production Line Jam Canned Production Line

Jam Canned Production Line Automatic Chicken Canned Food Production Line

Automatic Chicken Canned Food Production Line Potato Chips Instant Freezer

Potato Chips Instant Freezer Meat Pie Maker Machine

Meat Pie Maker Machine Meat Grinding Machine

Meat Grinding Machine Hydraulic Sausage Stuffer

Hydraulic Sausage Stuffer Small Scale Tomato Sauce Making Machine

Small Scale Tomato Sauce Making Machine