Food Canning Line Price - Chinese Manufacturer, Factory, Supplier

The Food Canning Line is a fully automated production system designed for a wide variety of canned products, including fish, meat, vegetables, fruits, sauces, and ready-to-eat meals. Its price varies depending on production capacity, automation level, can size, product type, and optional modules, but it represents a strategic investment for manufacturers seeking efficiency, hygiene, and high output.

Factors Affecting Food Canning Line Price

Production Capacity

Lines range from small-scale systems producing a few thousand cans per hour to industrial lines capable of 30,000–50,000 cans per hour. Higher capacity requires more robust filling, sealing, and sterilization equipment.Automation Level

Semi-automatic lines are less expensive but require more labor, while fully automatic systems with PLC control, integrated conveyors, and modular equipment cost more but offer higher efficiency, consistent quality, and reduced labor costs.Product Type & Can Material

The configuration depends on whether the line processes seafood, meat, vegetables, or sauces and whether cans are tinplate, aluminum, or glass jars. Special products, such as delicate seafood or high-acid sauces, require precise temperature and sterilization control, influencing overall cost.Optional Modules

Additional features such as vacuum filling, automatic labeling, CIP (Clean-in-Place) systems, retort sterilizers, or custom can handling conveyors can affect pricing.

Typical Price Ranges

Small-Scale Lines: $50,000–$120,000 – suitable for startups or low-volume production.

Medium-Scale Lines: $120,000–$350,000 – ideal for medium-sized factories with moderate output.

Large Industrial Lines: $350,000–$1,200,000+ – fully automated, high-capacity lines for large-scale production.

Why Invest in a Professional Food Canning Line

Ensures consistent product quality and hygiene.

Reduces labor costs through automation.

Complies with HACCP, ISO22000, and CE standards.

Provides scalable solutions for future expansion.

Integrates with packaging, labeling, and logistics systems for a turnkey solution.

Turnkey Solutions & Supplier Support

Leading manufacturers like Qingdao Hongshengyuanlin Co., Ltd. provide complete turnkey canning solutions, including:

Factory layout design

Equipment installation and commissioning

Operator training and technical support

Choosing a reliable supplier ensures optimal performance, energy efficiency, and long-term operational stability. Investing in a high-quality Food Canning Line enables your factory to achieve competitive production efficiency, superior product quality, and sustainable profitability.

Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Canned Meat Production Line

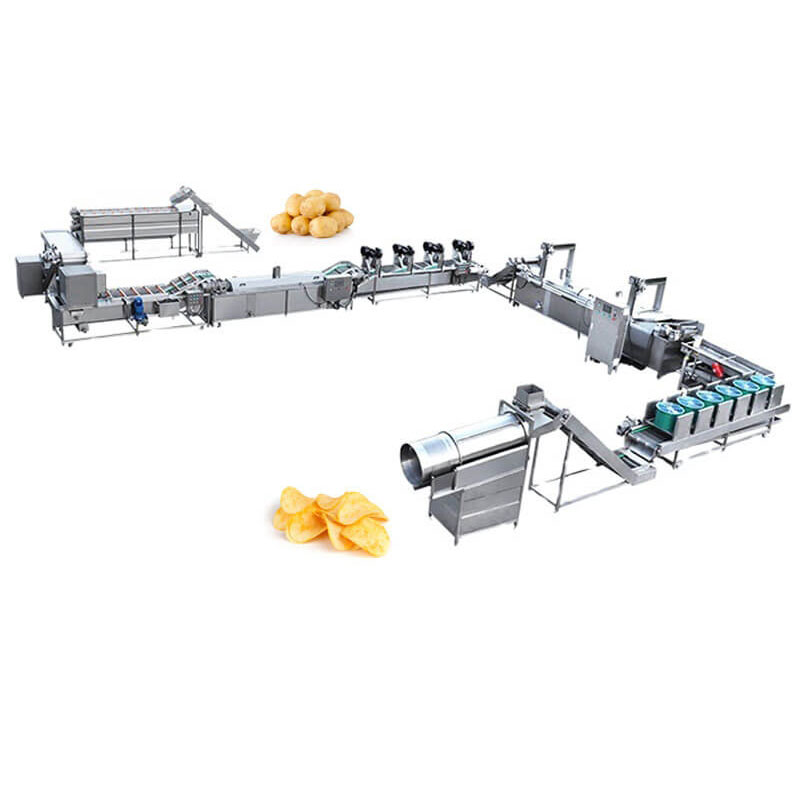

Canned Meat Production Line Automatic Potato Chips Production Line

Automatic Potato Chips Production Line Pork Skin Removing Machine

Pork Skin Removing Machine Gizzard Defatter

Gizzard Defatter Frozen Food Production Line

Frozen Food Production Line Mango Juice Processing Production Line

Mango Juice Processing Production Line SF Series Snowflake Ice Machine

SF Series Snowflake Ice Machine Automatic Rice Production Line

Automatic Rice Production Line Two-Stage Feeding (Minimum Height) Vertical Packaging System

Two-Stage Feeding (Minimum Height) Vertical Packaging System