Corn Flakes Manufacturing Machine - Chinese Manufacturer, Factory, Supplier

Looking for a reliable, high-performance corn flakes manufacturing machine to launch or scale your breakfast cereal business? Our state-of-the-art corn flakes production line combines advanced automation, food-grade safety standards, and energy-efficient design to deliver crispy, nutritious, and market-ready corn flakes at industrial scale. Ideal for food processing companies, startups, and OEM manufacturers worldwide, our turnkey solution covers every stage—from raw material preparation to final packaging.

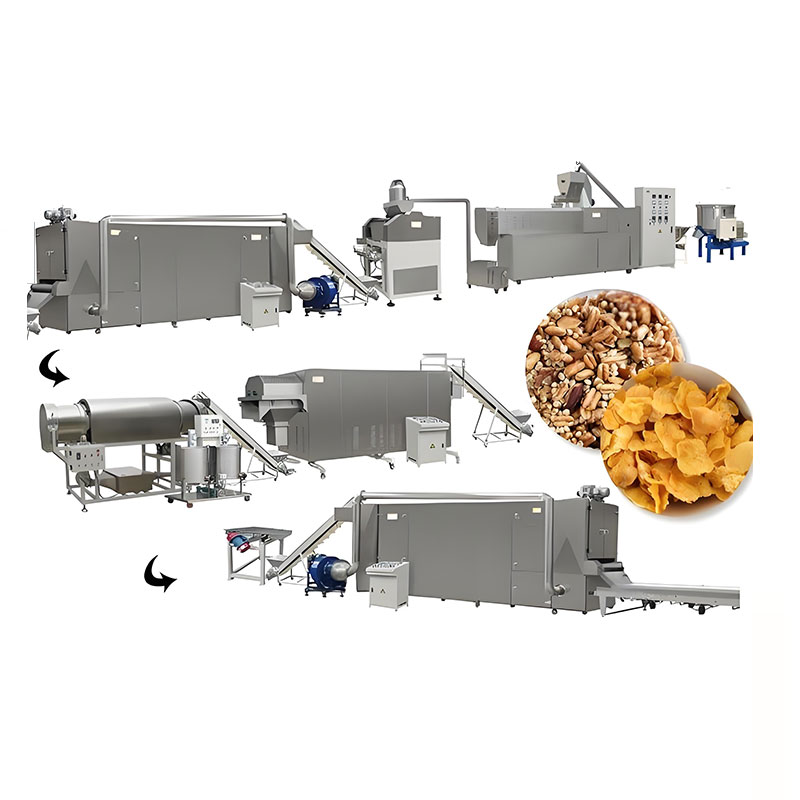

The corn flakes manufacturing process begins with maize grits conditioning and cooking under controlled temperature and pressure, followed by flaking, drying, toasting, and optional sugar coating. Our fully automated system ensures consistent product quality, minimal manual intervention, and compliance with international food safety regulations (including CE, ISO, and FDA standards). Key components include a continuous cooker, flaking rolls, multi-zone dryer, toaster, flavoring drum, and automatic packing machine—all seamlessly integrated for smooth operation.

Designed for versatility, our corn flakes machine can be customized to produce a variety of cereal shapes and flavors, including honey-glazed, chocolate-coated, or fortified variants enriched with vitamins and minerals. With capacities ranging from 100 kg/h to over 2,000 kg/h, we offer scalable solutions tailored to your production needs and budget. The compact layout saves factory space, while the user-friendly PLC control panel enables real-time monitoring and easy maintenance.

Backed by comprehensive after-sales support—including installation guidance, operator training, and spare parts supply—our corn flakes production line empowers businesses across Asia, Africa, the Middle East, Europe, and the Americas to meet rising global demand for healthy, ready-to-eat breakfast cereals. Whether you’re entering the health food market or expanding your existing product line, investing in a professional corn flakes manufacturing machine is your key to profitability, efficiency, and brand credibility.

Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Corn Canning Production Line

Corn Canning Production Line Corn Flakes Food Production Line

Corn Flakes Food Production Line Hydraulic Sausage Stuffer

Hydraulic Sausage Stuffer Smoked Furnace

Smoked Furnace Fish Deboner Machine

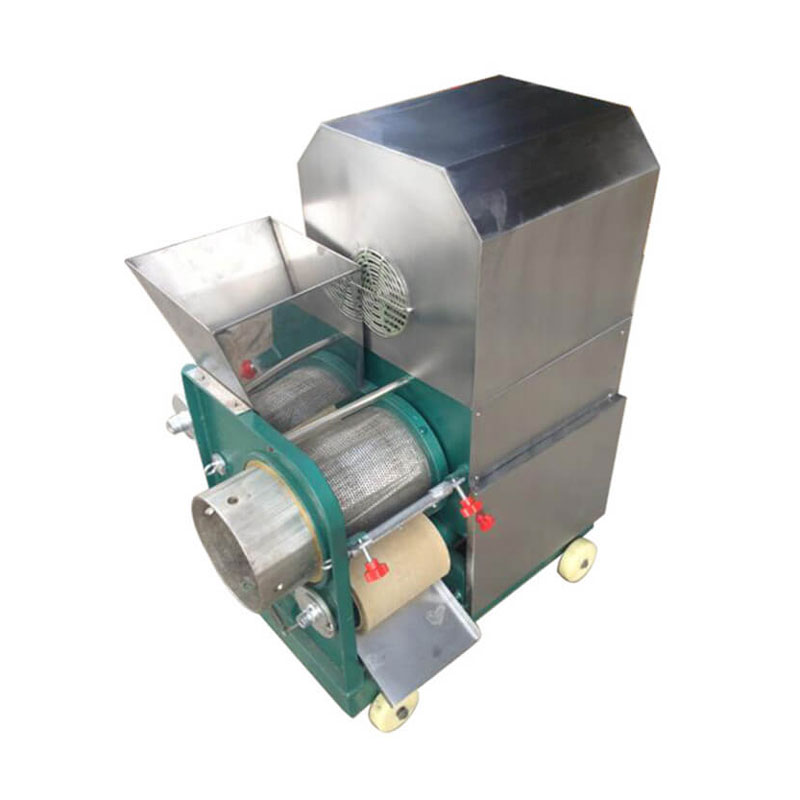

Fish Deboner Machine Deep-Fried Instant Noodle Production Line

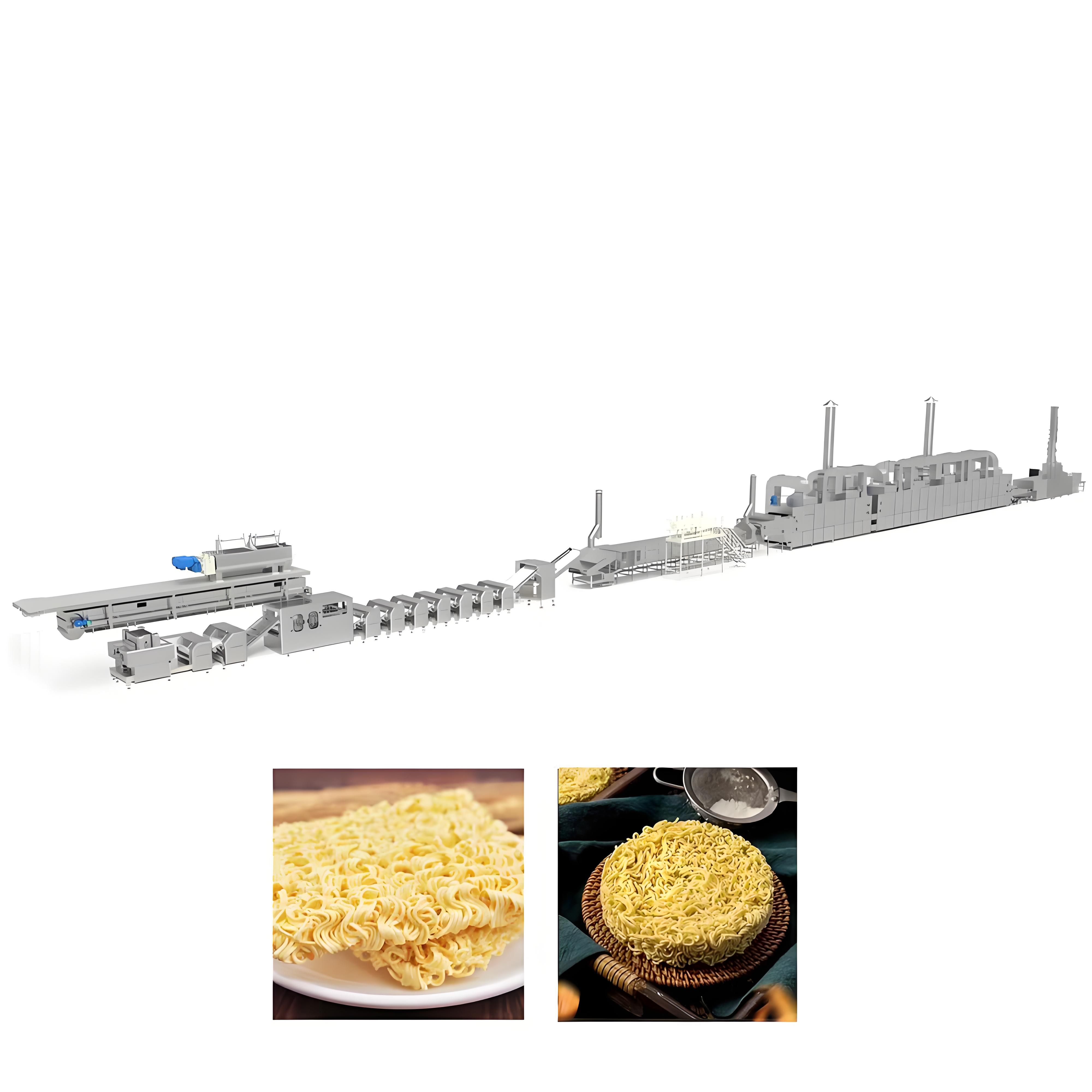

Deep-Fried Instant Noodle Production Line Chicken Slaughtering Machine

Chicken Slaughtering Machine Frozen French Fries Production Line

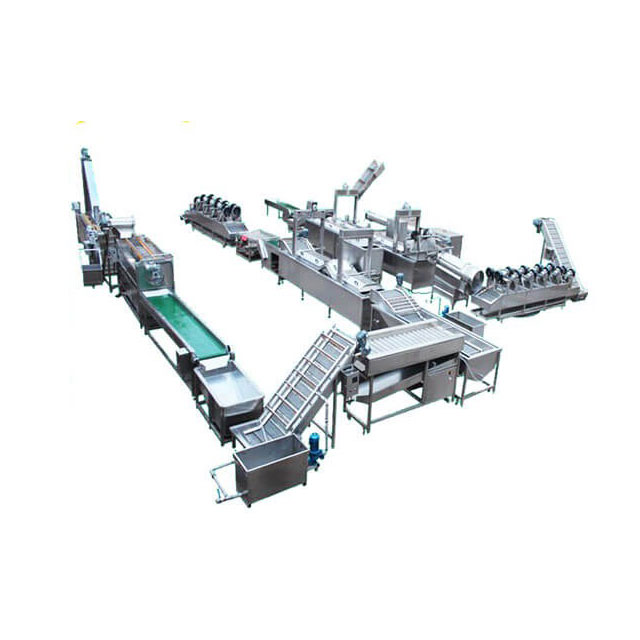

Frozen French Fries Production Line Vegetable Processing Line

Vegetable Processing Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment