Ice Cream Making Machine Factory - Chinese Manufacturer, Factory, Supplier

In today’s competitive frozen dessert industry, a high-quality ice cream making machine factory is essential for manufacturers seeking consistency, efficiency, and innovation. Modern factories are no longer just suppliers of machines—they provide complete production solutions that transform raw ingredients into delicious ice cream, gelato, frozen yogurt, and specialty desserts with precision and speed.

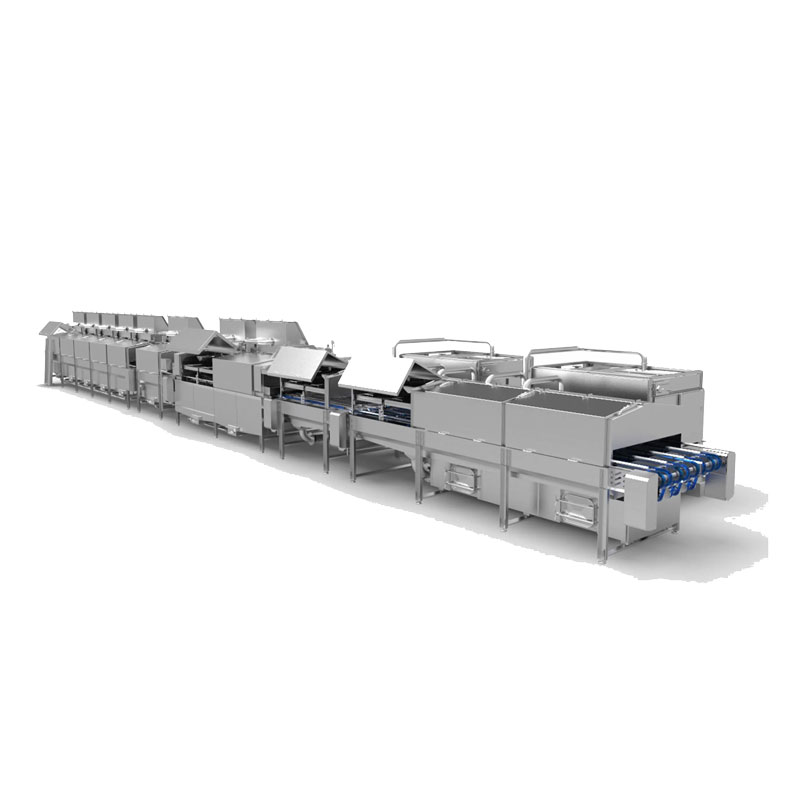

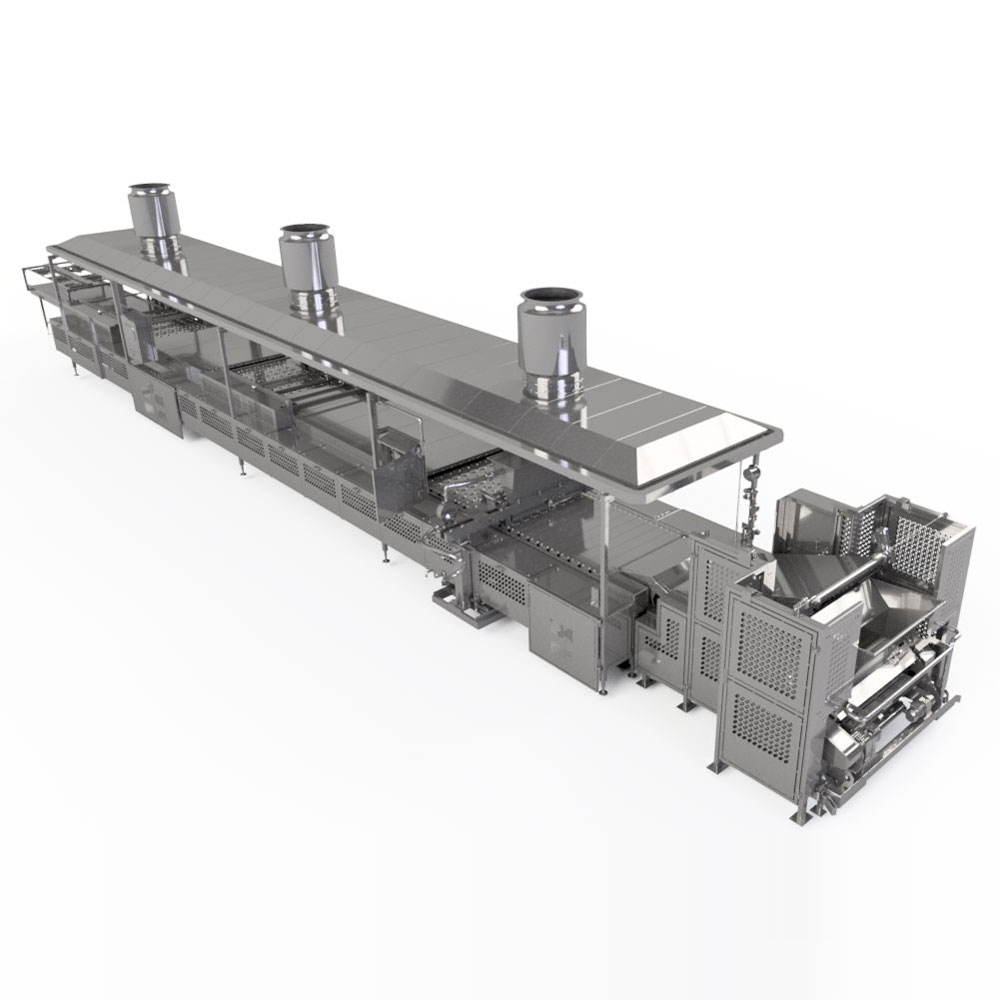

The production process begins with mixing and blending units, where milk, cream, sugar, stabilizers, and flavorings are combined into a smooth and uniform ice cream base. The mixture then passes through pasteurization systems, which carefully heat the mix to eliminate bacteria while maintaining flavor and nutrients. Following pasteurization, homogenizers evenly distribute fat and solids, ensuring a silky texture and preventing ice crystal formation.

Once homogenized, the mixture enters aging tanks, where it chills to 4°C and matures, allowing proteins and stabilizers to interact fully. The next stage, freezing, uses continuous or batch freezers that incorporate precise amounts of air (overrun), creating the creamy density and texture customers expect. Finally, the ice cream moves to filling and packaging units, which automatically portion the product into cups, tubs, cones, or bulk containers while maintaining strict hygiene standards.

Top ice cream machine factories design lines with flexible capacities, ranging from small artisanal setups producing 200–500 liters/day to large industrial plants exceeding 5,000 liters/day. Equipment is made from food-grade stainless steel (SS304/SS316) and features PLC or touchscreen control systems for real-time monitoring, process optimization, and quality assurance.

Qingdao Hongshengyuanlin Co., Ltd. is a recognized leader in the industry, offering turnkey ice cream production solutions worldwide. From factory layout and customized machine fabrication to installation and operator training, Hongshengyuanlin combines engineering expertise, global project experience, and automation technology to deliver reliable, efficient, and cost-effective production lines. Their projects span Asia, Africa, and the Middle East, meeting international standards such as HACCP, ISO22000, and CE.

Choosing a trusted ice cream making machine factory ensures consistent product quality, reduced labor costs, high production efficiency, and faster time-to-market. Whether launching a boutique gelato brand or expanding a large industrial plant, a turnkey production line from a professional manufacturer like Hongshengyuanlin provides the foundation for long-term success in the frozen dessert market.

Types of Ice Cream Machines & Applications

| Category | Main Equipment | Core Function | Typical Applications |

|---|---|---|---|

| Mixing & Blending | High-speed mixers, batch blenders | Combine milk, cream, sugar, stabilizers, and flavorings into a uniform ice cream base | Soft serve, gelato, frozen yogurt, hard ice cream |

| Pasteurization | Plate pasteurizers, tubular pasteurizers | Heat mixture to eliminate microorganisms while preserving taste and nutrients | All types of ice cream bases |

| Homogenization | High-pressure homogenizers | Ensure even fat distribution and prevent ice crystal formation | Creamy ice cream, gelato, premium frozen desserts |

| Aging Tanks | Chilling and maturation tanks | Chill mixture to 4°C and allow stabilizers/proteins to interact | Soft serve, hard ice cream, frozen yogurt |

| Freezing Units | Continuous freezers, batch freezers | Rapidly freeze mixture while incorporating controlled air (overrun) | Soft serve, gelato, hard ice cream |

| Filling & Packaging | Cup fillers, tub fillers, cone fillers, bulk packers | Portion and package ice cream hygienically and efficiently | Retail cups, tubs, cones, bulk containers |

| Cooling & Storage | Blast chillers, cold storage tanks | Preserve ice cream quality before distribution | Soft serve and hard ice cream storage |

| Automation & Control Systems | PLC panels, touchscreen interfaces, sensors | Centralized monitoring of temperature, overrun, and production parameters | Fully automated ice cream production lines |

| Quality Control & Inspection | Metal detectors, vision systems, weight checkers | Ensure product safety, uniformity, and compliance | All frozen dessert products |

| Auxiliary Equipment | Ingredient feeders, conveyors, CIP systems | Support main production line and maintain hygiene | Ingredient dosing, mix transfer, line cleaning |

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Fish Slicer Machine

Fish Slicer Machine AF Series Flake Pellet Ice Machine

AF Series Flake Pellet Ice Machine SC Series Bullet Ice Maker

SC Series Bullet Ice Maker SF Series Snowflake Ice Machine

SF Series Snowflake Ice Machine AP Series Flake Ice Machine

AP Series Flake Ice Machine SY-168 / SY-158 Commercial Ice Shaver Machine

SY-168 / SY-158 Commercial Ice Shaver Machine Pelmeni Making Machine

Pelmeni Making Machine Dutch Canned Fish Production Line

Dutch Canned Fish Production Line Commercial Dry Pasta Machine

Commercial Dry Pasta Machine Shrimp Processing Line

Shrimp Processing Line Beverage Production Line

Beverage Production Line Pancake Production Line

Pancake Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Chicken Slaughtering Machine

Chicken Slaughtering Machine