Customized Tomato Paste Packing Machine - Chinese Manufacturer, Factory, Supplier

A customized tomato paste packing machine is an advanced solution designed for food processors who require precision, efficiency, and flexibility in handling viscous products such as tomato paste, ketchup, and concentrated sauces. Unlike standard models, this type of equipment is tailored to meet specific production needs—whether that means unique packaging sizes, specialized materials, or integration into existing production lines.

At its core, the machine is engineered to handle the challenges of tomato paste’s dense, sticky texture. With high-precision piston or servo-driven filling systems, it guarantees accurate volume control and minimizes product waste. This ensures that each pouch, sachet, jar, or bottle maintains consistent weight and quality, a critical factor for meeting both domestic regulations and international export requirements.

One of the defining advantages of a customized tomato paste packing machine is its packaging versatility. It can be configured for a wide range of formats, including sachets, doypacks, glass jars, PET bottles, or even bulk containers like 2L–220L aseptic bags. This adaptability gives food manufacturers the ability to cater to different markets, from household retail to foodservice and industrial sectors.

Hygiene and food safety are built into the design. The machines are typically manufactured with stainless steel contact parts, clean-in-place (CIP) systems, and sealed filling environments that comply with HACCP, GMP, and ISO standards. Advanced sterilization features can also be integrated, particularly for aseptic packaging solutions that extend shelf life without compromising freshness.

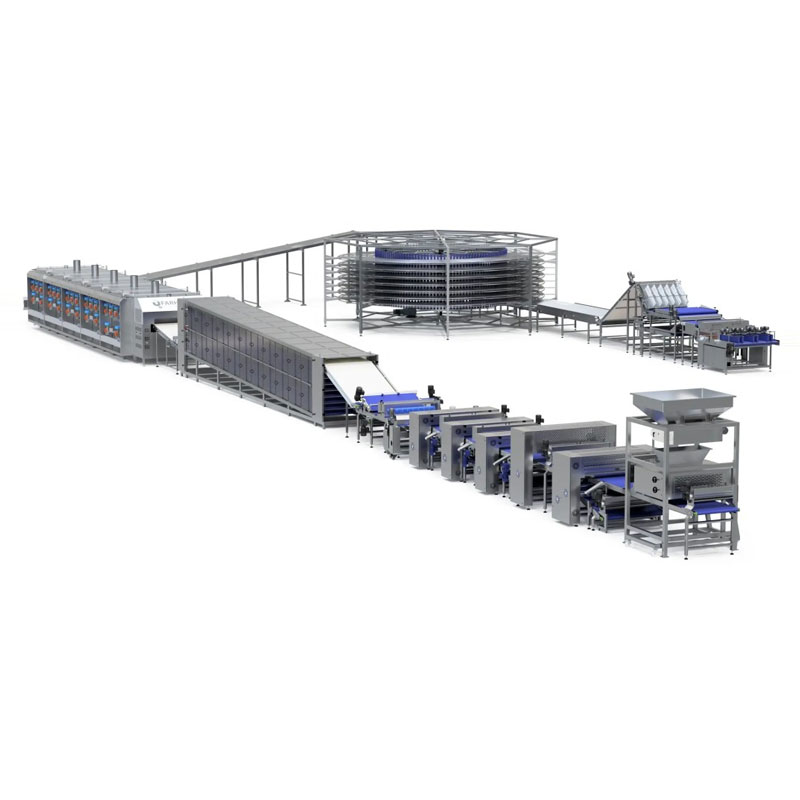

Automation plays a central role, with features such as PLC control panels, touchscreen interfaces, and programmable settings that allow operators to adjust filling volumes, sealing strength, and production speed with ease. When customized, the system can be synchronized with upstream and downstream equipment—such as paste cooking machines, capping machines, labeling systems, and carton packers—forming a fully automated production line.

The benefits extend beyond efficiency. By reducing manual handling, the machine minimizes contamination risks, enhances product safety, and ensures uniform output. Moreover, customization enables manufacturers to optimize energy consumption, lower maintenance costs, and scale capacity according to demand.

For producers targeting competitive markets, a customized tomato paste packing machine is not only a tool for operational excellence but also a gateway to building stronger brand reputation. By delivering consistent quality and adapting to diverse consumer preferences, it helps companies secure long-term growth in both local and global food sectors.

Small Scale Tomato Sauce Making Machine

Small Scale Tomato Sauce Making Machine Tomato Sauce Milling Machine

Tomato Sauce Milling Machine Tomato Sauce Grinding Machine

Tomato Sauce Grinding Machine Pasteurized Milk Processing Line

Pasteurized Milk Processing Line Tomato Juice Processing Production Line

Tomato Juice Processing Production Line Tomato Sauce Machine

Tomato Sauce Machine Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine Tomato Ketchup Processing Line

Tomato Ketchup Processing Line Paste Grinding Machine

Paste Grinding Machine Tomato Paste Production Line

Tomato Paste Production Line Canned Sardine Production Line Equipment

Canned Sardine Production Line Equipment Chicken Plucker Machine

Chicken Plucker Machine Gizzard Defatter

Gizzard Defatter Bowl Cutter

Bowl Cutter Automatic Fish Filleting Machine

Automatic Fish Filleting Machine Blast Freezer

Blast Freezer Pita Production Line

Pita Production Line Microwave Pigskin Puffing Machine

Microwave Pigskin Puffing Machine