Frozen Meat Dicer Machine - Chinese Manufacturer, Factory, Supplier

The frozen meat dicer machine is a revolutionary tool redefining the standards of precision and productivity in food processing. Engineered to handle the unique challenges of cutting frozen meat into uniform, high-quality pieces, this machine combines cutting-edge technology with rugged durability, ensuring consistent results even at industrial scales. Whether slicing poultry, seafood, or red meat, it transforms frozen blocks into perfectly cubed or diced portions with minimal effort and maximum efficiency.

At its core lies advanced cryogenic cutting technology. The frozen meat dicer machine utilizes diamond-coated blades and hydraulically powered mechanisms to slice through frozen materials with surgical precision. Unlike traditional methods that risk uneven cuts or thawing, this machinery maintains the integrity of the product by operating at sub-zero temperatures. The result? Consistent portion sizes, reduced waste, and enhanced product aesthetics—critical factors for retailers and foodservice providers.

One of its standout features is automation. Equipped with programmable settings and sensor-driven controls, the machine adapts to varying meat densities, adjusting blade pressure and speed in real time. This not only extends blade longevity but also ensures uniformity across batches. Operators can pre-set dice dimensions—from petite cubes for soups to larger chunks for stir-fries—eliminating manual adjustments and saving hours of labor.

The China Yuanlin Factory , a global leader in food processing equipment, manufactures these machines to exacting standards. With decades of expertise, the factory integrates innovations like self-sharpening blades and corrosion-resistant alloy components, ensuring machines withstand the rigors of 24/7 operation. Each unit undergoes rigorous testing for noise reduction, energy efficiency, and compliance with international food safety protocols, such as HACCP and FDA guidelines.

Beyond functionality, the frozen meat dicer machine offers economic advantages. By minimizing manual labor and reducing material waste, it lowers operational costs while boosting output. Its compact design also allows seamless integration into existing production lines, making it ideal for both small-scale processors and large industrial facilities.

The China Yuanlin Factory ’s commitment to sustainability shines through energy-efficient motors and recyclable materials in machine construction. This eco-conscious approach aligns with global trends toward responsible manufacturing, positioning businesses that adopt these tools as industry leaders in innovation and environmental stewardship.

In an era where food processors demand precision, speed, and reliability, the frozen meat dicer machine from the China Yuanlin Factory emerges as an indispensable asset. It not only elevates product quality but also future-proofs operations against evolving market demands. For businesses striving to meet the highest standards of efficiency and consistency, this machinery is more than a tool—it’s a gateway to excellence.

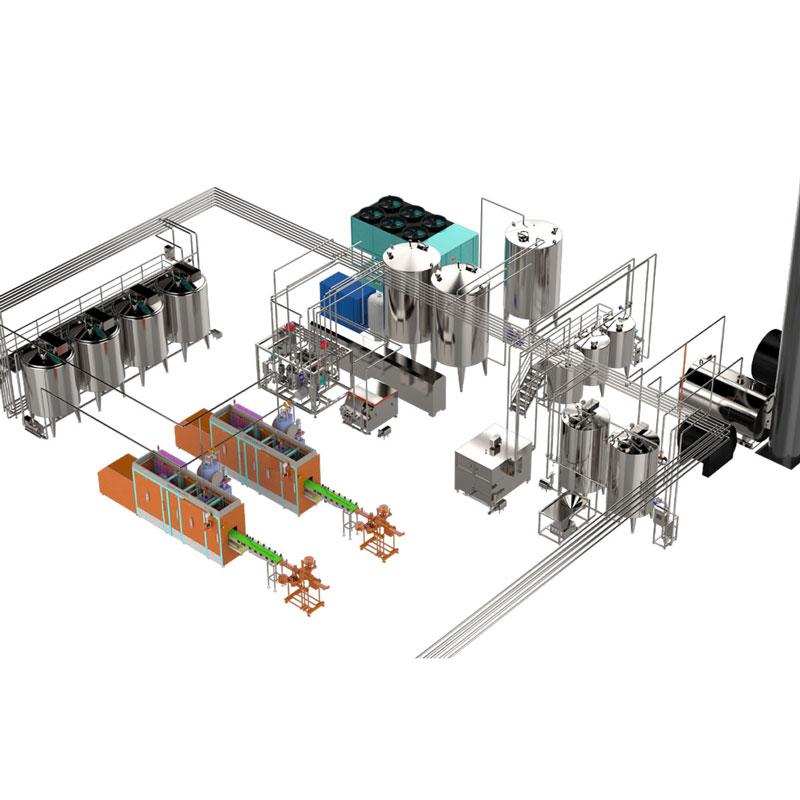

Meat Canned Food Production Line

Meat Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Pet Fish Meat Canning Production Line

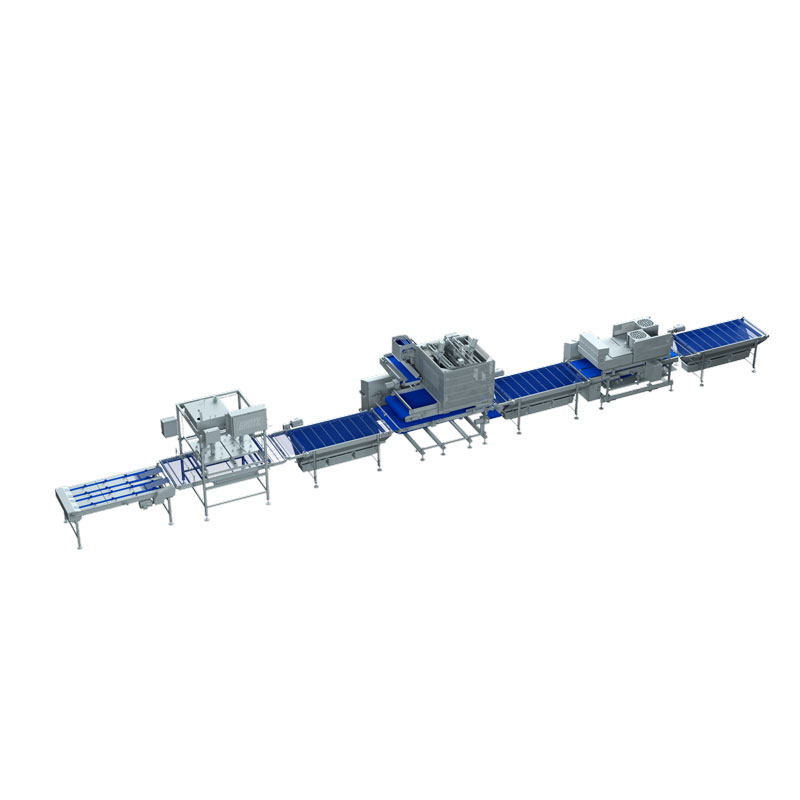

Pet Fish Meat Canning Production Line Fully Automatic Meat Can Production Lines

Fully Automatic Meat Can Production Lines Heavy Duty Commercial Meat Grinder

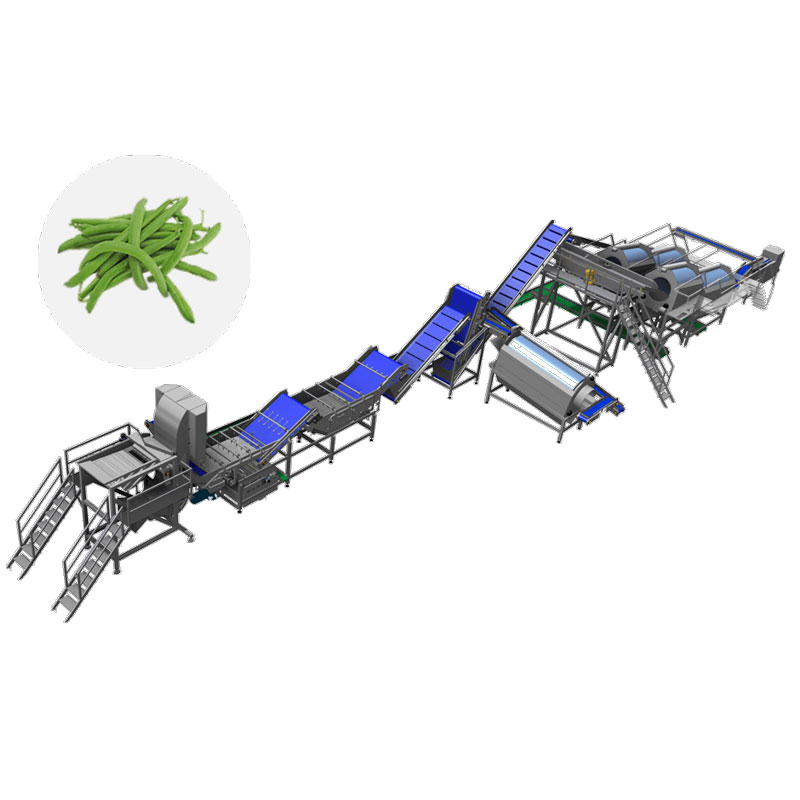

Heavy Duty Commercial Meat Grinder Frozen Food Production Line

Frozen Food Production Line Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

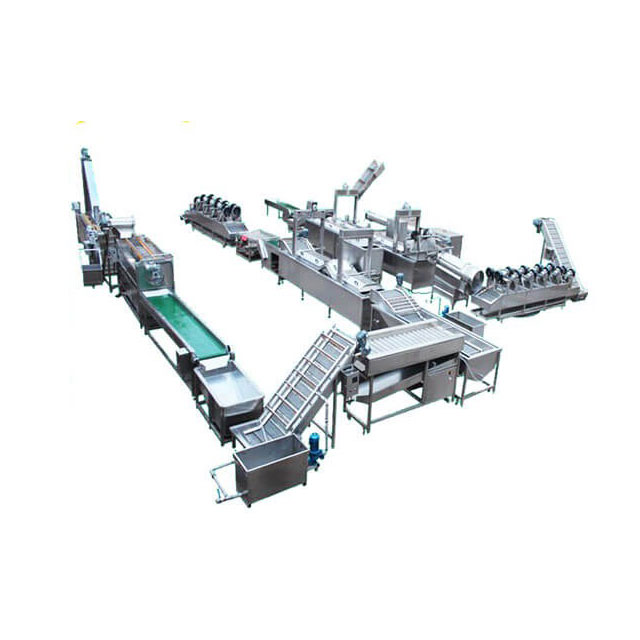

Automatic Meat Slicer Machine Spinach Canned Canned Food Canning Production Line

Spinach Canned Canned Food Canning Production Line Potato Chip Line

Potato Chip Line Frozen French Fries Production Line

Frozen French Fries Production Line Small Scale Banana Chips Production Line

Small Scale Banana Chips Production Line Yogurt Production Line

Yogurt Production Line SD-3000 / SD-4000 Commercial Cube Ice Maker

SD-3000 / SD-4000 Commercial Cube Ice Maker Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Fully Automated Pizza Production Line

Fully Automated Pizza Production Line