Meat Food Processing Equipment - Chinese Manufacturer, Factory, Supplier

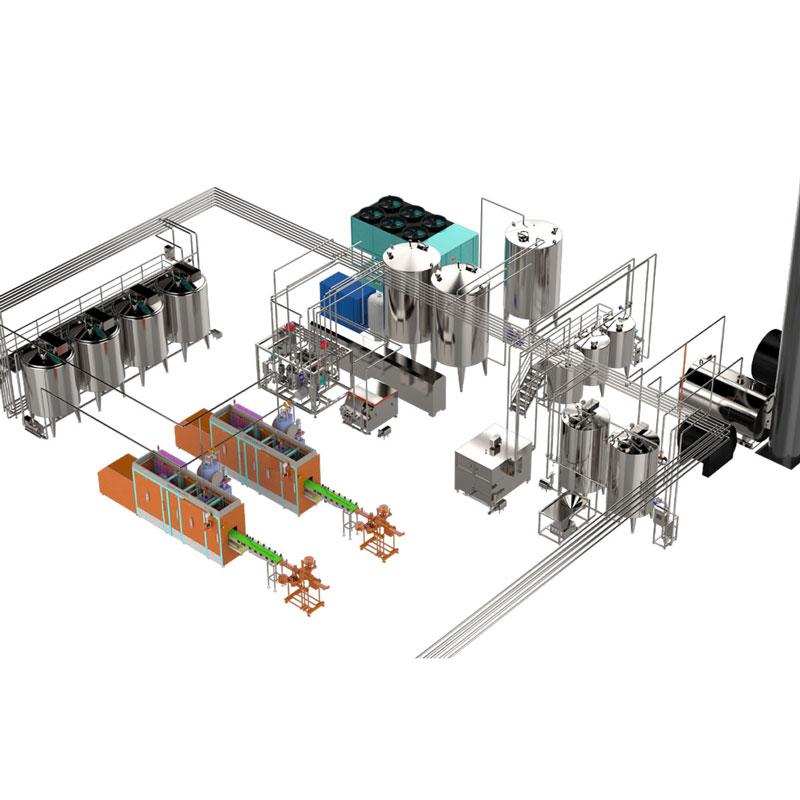

Efficient, hygienic, and consistent production is the backbone of the meat industry, and premium Meat Food Processing Equipment plays a pivotal role in achieving it. Designed for large-scale commercial operations as well as specialized meat processors, this equipment transforms raw cuts into market-ready products with speed and accuracy.

Modern Meat Food Processing Equipment encompasses a wide range of machines—industrial slicers, grinders, dicers, tenderizers, tumblers, and bowl cutters—each engineered for a specific stage in the production chain. These systems handle beef, pork, poultry, and specialty meats with precise portioning and texture control, ensuring every piece meets exacting standards.

Hygiene and food safety are paramount. High-grade Meat Food Processing Equipment is constructed from corrosion-resistant stainless steel with seamless welds and non-porous surfaces to prevent bacterial build-up. Quick-release components and tool-free disassembly enable fast, thorough cleaning, ensuring compliance with HACCP, ISO 22000, and other global safety certifications.

Automation is a defining feature of advanced Meat Food Processing Equipment. With programmable logic controllers (PLCs), automated feed systems, and precision cutting mechanisms, manufacturers can reduce manual handling, maintain consistent output, and improve yield. Real-time monitoring systems ensure optimal performance and allow adjustments without halting production.

Flexibility is another key advantage. The best Meat Food Processing Equipment can adapt to different meat types, cuts, and processing requirements, making it suitable for both high-volume facilities and custom product lines. Optional attachments and modular designs allow easy upgrades as production needs evolve.

Beyond machinery, reliable suppliers of Meat Food Processing Equipment provide installation, operator training, preventive maintenance, and rapid spare parts support—helping businesses maintain peak efficiency and minimize downtime.

For meat processors aiming to boost productivity, ensure product uniformity, and maintain stringent hygiene standards, investing in the right Meat Food Processing Equipment is a strategic decision that drives profitability and long-term operational success.

Heavy Duty Commercial Meat Grinder

Heavy Duty Commercial Meat Grinder Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Meat Stuffer Machine

Meat Stuffer Machine Meat Tenderizer

Meat Tenderizer Household Meat Grinder

Household Meat Grinder Automatic Meat Tumbling Machine

Automatic Meat Tumbling Machine Full-automatic Meat Smoke Oven

Full-automatic Meat Smoke Oven Dairy Processing Lines

Dairy Processing Lines Cold Chain Rice Production Line

Cold Chain Rice Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Yogurt Production Line

Yogurt Production Line Beverage Production Line

Beverage Production Line Automatic Fresh Meat Dicing Machine

Automatic Fresh Meat Dicing Machine