Chop Meat Machine China - Chinese Manufacturer, Factory, Supplier

The demand for high-quality minced meat—whether for burgers, sausages, or ready-to-cook meals—has never been higher. At the core of this supply chain lies advanced chop meat machines, and China has cemented its role as a global leader in designing and manufacturing these indispensable tools. Combining innovation, durability, and compliance with international standards, Meat Equipment China providers are reshaping the way processors meet modern culinary demands.

Engineering Excellence in Meat Processing

Modern chop meat machines from China are marvels of engineering. Take, for instance, the China yuanlin factory, a trailblazer in industrial food machinery. Their flagship models feature dual-stage grinding systems with titanium-coated blades that maintain sharpness through thousands of cycles. These machines also integrate AI-driven texture adjustment, allowing operators to fine-tune particle size from coarse chili con carne bases to silky pâté consistencies. Such precision minimizes waste and maximizes yield—critical for businesses targeting tight margins.

A 2023 report by the International Food Machinery Association highlighted that Chinese-made choppers reduce energy consumption by 25% compared to conventional models. This efficiency stems from innovations like variable-frequency drives, which adjust motor speed based on load, and self-cooling bearings that eliminate downtime for maintenance.

Hygiene and Compliance: Non-Negotiable Standards

Food safety is paramount. Meat Equipment China manufacturers prioritize designs that meet ISO 22000 and CE certifications, ensuring machines withstand rigorous sanitation protocols. The China yuanlin factory, for example, uses stainless steel alloys with antimicrobial coatings to inhibit bacterial growth. Their machines also feature seamless welds and removable components, simplifying deep cleaning—a factor praised in a Global Meat Industry case study for reducing microbial risks by 40%.

Sustainability Meets Scalability

China’s focus on eco-conscious production is evident. Many chop meat machines now include energy recovery systems that repurpose heat generated during operation to preheat incoming meat batches. The China yuanlin factory has taken this further by partnering with renewable energy providers to power facilities with solar energy, aligning with the UN’s Sustainable Development Goals.

Customization is another strength. Whether processing halal-certified lamb, organic pork, or plant-based meat alternatives, Chinese manufacturers offer modular configurations. Quick-change blade cassettes and hydraulic pulse mincers enable rapid shifts between product lines, a feature leveraged by multinational brands to diversify offerings without capital-intensive retooling.

Trust Through Transparency

China’s dominance in this sector is backed by data. According to Statista, the country accounts for 38% of global meat machinery exports, driven by competitive pricing and adherence to EU and USDA guidelines. The China yuanlin factory further enhances trust through real-time remote monitoring systems, allowing clients to track machine performance and maintenance needs via cloud platforms.

Conclusion

For processors seeking reliability and innovation, chop meat machines from China offer an unmatched blend of technology and value. From the cutting-edge engineering of the China yuanlin factory to the globally compliant solutions of Meat Equipment China, these machines empower businesses to deliver consistent quality while future-proofing operations. In a sector where precision and efficiency define success, partnering with Chinese experts isn’t just strategic—it’s essential.

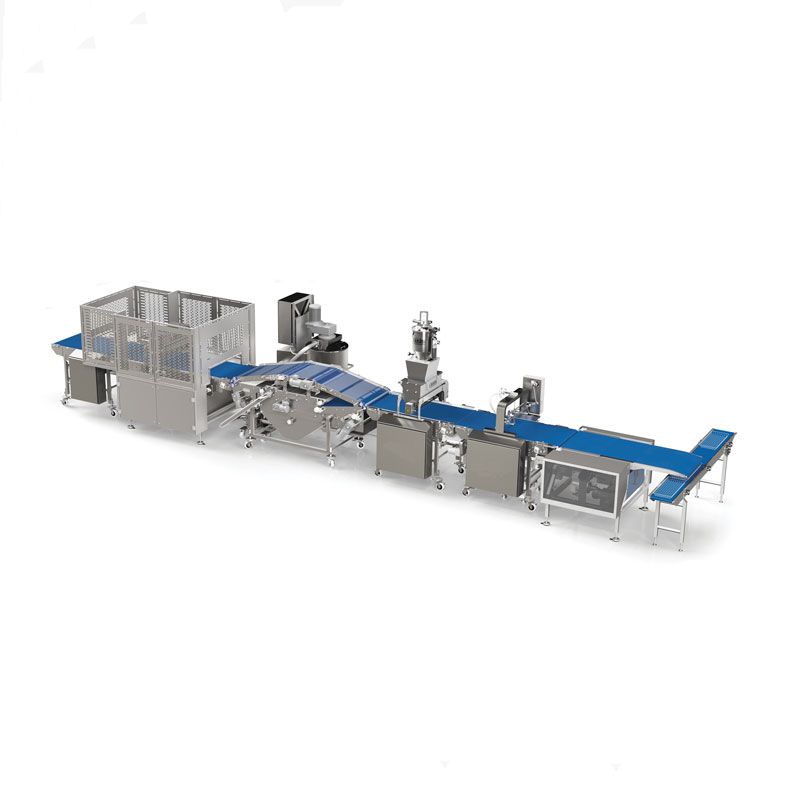

Meat Canned Food Production Line

Meat Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line Fully Automatic Meat Can Production Lines

Fully Automatic Meat Can Production Lines Heavy Duty Commercial Meat Grinder

Heavy Duty Commercial Meat Grinder Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine Automatic Meat Slicer Machine

Automatic Meat Slicer Machine Meat Pie Maker Machine

Meat Pie Maker Machine Meat Cuber Machine

Meat Cuber Machine Chop Meat Machine

Chop Meat Machine Fried Food Deoiling Machine

Fried Food Deoiling Machine Tomato Sauce Machine

Tomato Sauce Machine Apple Canning Production Line

Apple Canning Production Line Fresh Meat Slicing Portioning Machine

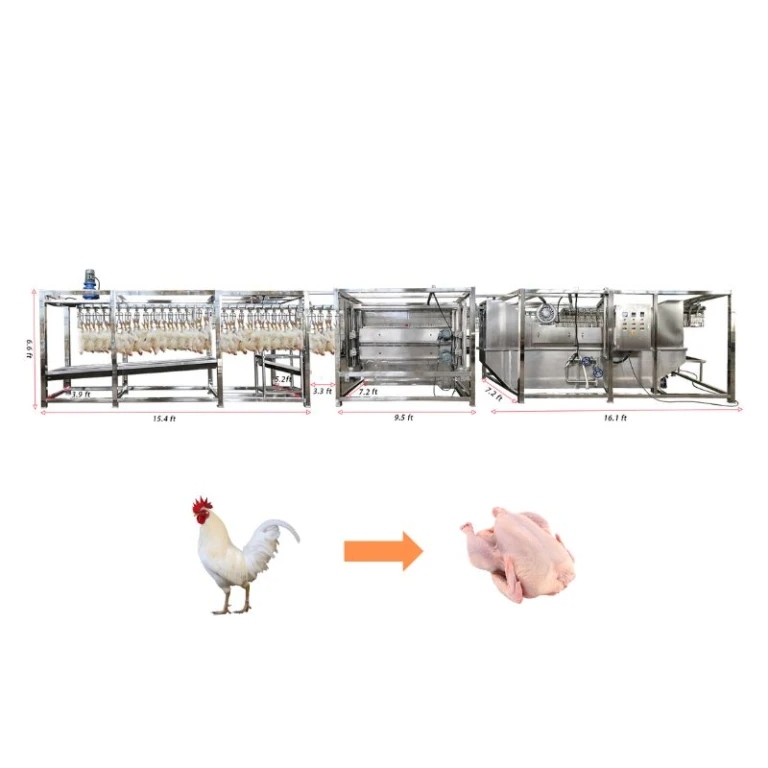

Fresh Meat Slicing Portioning Machine Chicken Production Line

Chicken Production Line Donut Production Line

Donut Production Line SD Square Ice Series Upright Ice Makers

SD Square Ice Series Upright Ice Makers Fish Slicer Machine

Fish Slicer Machine