155g Canned Sardines Production Line - Chinese Manufacturer, Factory, Supplier

The 155g sardine can production line is a specialized solution designed to meet the growing global demand for ready-to-eat canned sardines. Tailored to the most common consumer packaging size—155 grams—this production line ensures precision, efficiency, and compliance with international food safety standards. From raw fish handling to final packaging, the system integrates advanced technologies to deliver consistency in quality and taste.

At the heart of the process is raw material preparation. Fresh sardines are thoroughly cleaned, sorted, and pre-cooked to maintain nutritional value and natural flavor. The 155g sardine can production line is engineered to handle high volumes with minimal manual intervention, reducing labor costs while improving output speed. Automated conveying systems transfer fish to filling stations, where pre-calibrated equipment ensures each can is filled with exact portions, guaranteeing weight accuracy and portion consistency.

Sealing technology is another critical component. Precision can seamers create airtight seals that preserve freshness and extend shelf life. The line can accommodate tinplate or aluminum cans, depending on customer requirements. Advanced vacuum and steam injection systems help remove oxygen during sealing, protecting the sardines from spoilage and oxidation.

Sterilization is conducted in high-capacity retort systems that meet HACCP, FDA, and EU food safety regulations. These autoclaves ensure that the final product is shelf-stable for extended periods without compromising taste, texture, or nutritional content. After sterilization, cans are cooled, dried, and automatically conveyed to labeling and packaging stations. High-speed labeling machines apply product labels with precision, while automated carton packing units prepare finished goods for shipment.

The 155g sardine can production line is fully customizable, allowing food manufacturers to adjust filling, seasoning, and packaging configurations. Options such as adding sauces (tomato, chili, or oil-based) can be integrated seamlessly. Production capacity ranges from small-scale units for local seafood processors to fully automated industrial systems capable of producing thousands of cans per hour.

Built from food-grade stainless steel and engineered for easy cleaning, the line supports strict hygiene requirements. Its modular design allows integration with upstream operations such as fish cleaning machines and downstream logistics like palletizing systems. Manufacturers like Qingdao Hongshengyuanlin Co., Ltd., established in 2014, provide advanced sardine canning solutions and technical support, ensuring reliable operation and long-term return on investment.

By adopting a 155g sardine can production line, seafood processors can meet consumer expectations for convenience, maintain consistent product quality, and expand into international markets with confidence. This equipment is not just about automation—it is about elevating production efficiency while ensuring food safety and brand credibility.

Egg Canning Production Line

Egg Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Cucumber Canned Production Line

Cucumber Canned Production Line Canned Beans Production Line

Canned Beans Production Line Jam Canned Production Line

Jam Canned Production Line Pet Canned Food Production Line

Pet Canned Food Production Line Fruit And Vegetable Canned Production Line

Fruit And Vegetable Canned Production Line Food X-ray Foreign Object Detector

Food X-ray Foreign Object Detector Churros Making Machine

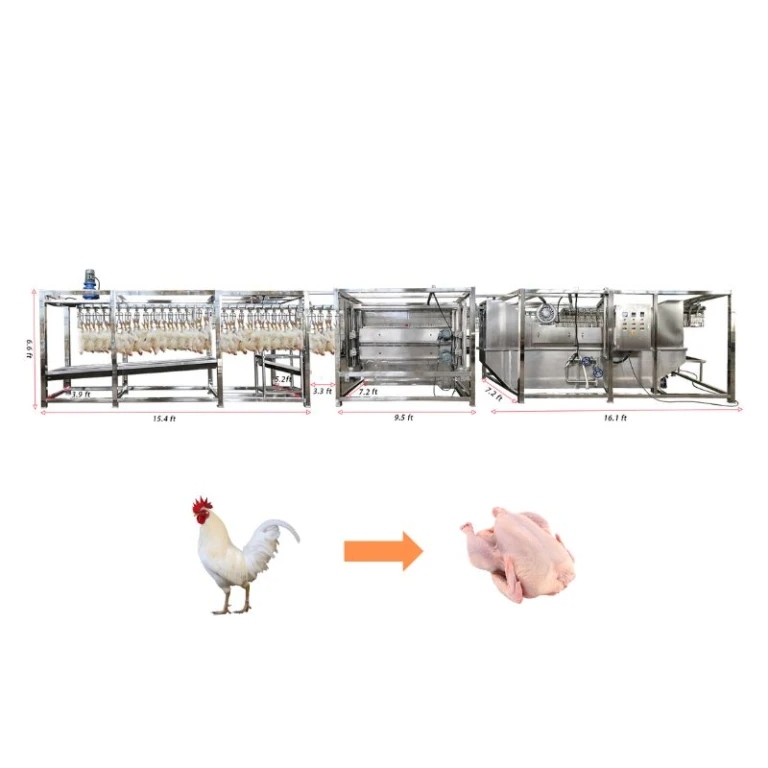

Churros Making Machine Chicken Production Line

Chicken Production Line Electric Cooked Meat Slicer

Electric Cooked Meat Slicer Meat Tenderizer

Meat Tenderizer Standard Vertical Weighing and Packaging System

Standard Vertical Weighing and Packaging System Commercial Electromagnetic Cooker

Commercial Electromagnetic Cooker Centrifugal Dewatering Machine

Centrifugal Dewatering Machine