Noodle Production Line - Chinese Manufacturer, Factory, Supplier

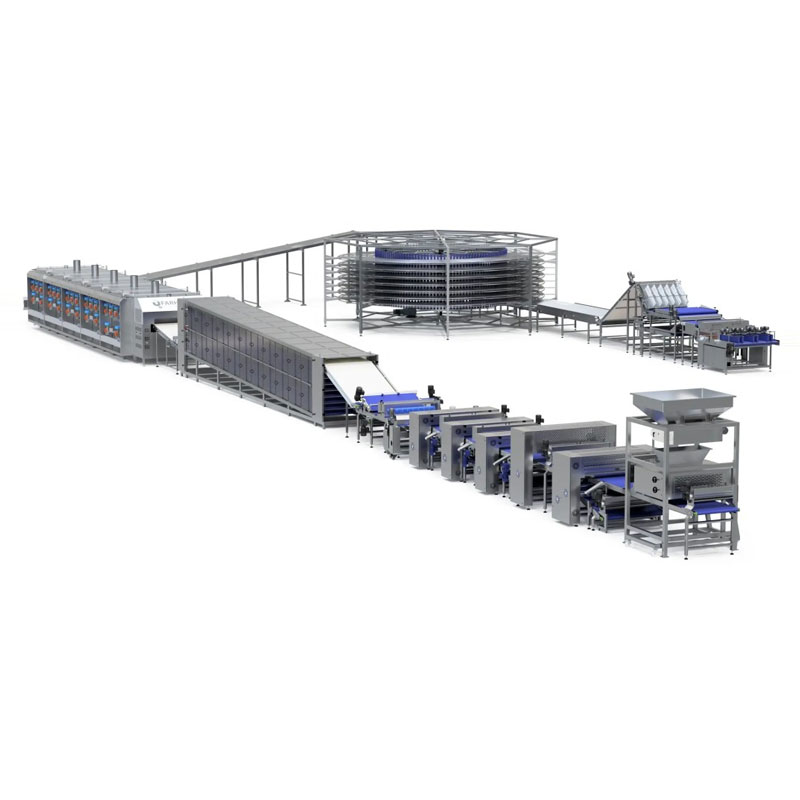

Industrial pasta manufacturing depends on sophisticated noodle production line systems that transform simple ingredients into diverse pasta configurations through precise mechanical processing. These automated installations combine traditional pasta-making principles with advanced engineering to achieve consistent texture, appearance, and cooking characteristics across high-volume production runs.

Flour preparation begins every noodle production line through sifting mechanisms that remove impurities while achieving uniform particle distribution. Pneumatic conveying systems transport flour to storage silos equipped with weight-loss feeders that deliver precise quantities to mixing stations. Ingredient dosing accuracy directly influences final product quality and consistency throughout production cycles.

Dough formation occurs within continuous mixers featuring specialized paddle configurations that incorporate liquid ingredients into flour matrices. These machines develop gluten structures through controlled mechanical energy while maintaining optimal hydration levels essential for proper dough elasticity and workability.

Sheeting operations represent critical phases within any noodle production line where dough passes through sequential reduction rollers that gradually decrease thickness to specified dimensions. Gap settings, roller speeds, and dough tension parameters require precise coordination to prevent tearing while achieving uniform thickness across the entire dough sheet width.

Cutting mechanisms transform continuous dough sheets into individual noodle strands through rotary cutters, reciprocating blades, or extrusion dies depending on desired pasta geometry. These systems maintain consistent strand width while preventing adhesion between adjacent noodle pieces during cutting operations.

Drying represents the most complex aspect of noodle production line processing through multi-stage thermal treatment that reduces moisture content while preserving structural integrity. Controlled atmosphere chambers regulate temperature, humidity, and airflow patterns to prevent case hardening while ensuring uniform moisture removal throughout product cross-sections.

Pre-drying phases utilize gentle heat application that initiates surface moisture evaporation without creating thermal stress gradients. Intermediate drying stages employ higher temperatures with precise humidity control to continue moisture removal while maintaining product flexibility.

Final drying operations within noodle production line systems achieve target moisture levels through extended residence times in temperature-controlled environments. These phases stabilize products for extended shelf life while preventing microbial growth during storage and distribution.

Quality assurance protocols include moisture analysis, color measurement, and cooking quality evaluation through automated testing equipment. Optical sorting systems identify and remove defective products based on predetermined appearance parameters.

Modern noodle production line installations achieve production capacities exceeding 500 kilograms per hour while maintaining consistent cooking characteristics and textural properties that satisfy consumer expectations for premium pasta products across diverse market segments.

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Robotic Rice Production Line

Robotic Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line Aseptic Rice Production Line

Aseptic Rice Production Line Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Automatic Chicken Canned Food Production Line

Automatic Chicken Canned Food Production Line Meat Shredding Machine

Meat Shredding Machine Pita Production Line

Pita Production Line Sausage Stuffer Machine

Sausage Stuffer Machine Centrifugal Dewatering Machine

Centrifugal Dewatering Machine Quantitative Vacuum Sausage Filler

Quantitative Vacuum Sausage Filler