Poultry Processing Equipment Manufacturers - Chinese Manufacturer, Factory, Supplier

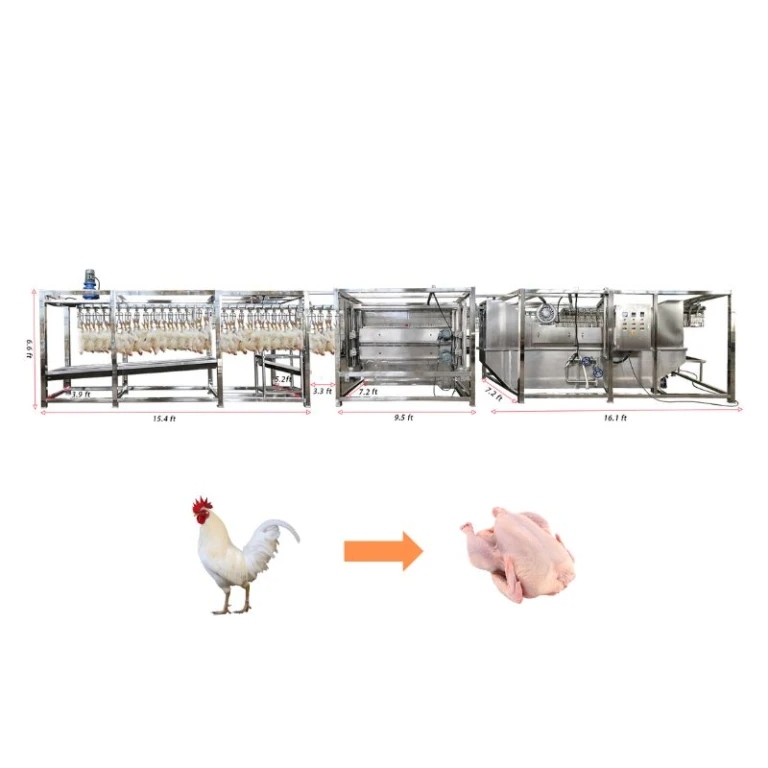

Leading poultry processing equipment manufacturers in China, such as Qingdao Hongshengyuanlin Co., Ltd., specialize in providing advanced, fully automated solutions for the modern poultry industry. Their equipment covers every stage of processing — from slaughtering and defeathering to cutting, deboning, chilling, and packaging — ensuring maximum hygiene, efficiency, and product consistency.

Modern poultry plants require integrated systems that meet international food safety standards like HACCP, ISO22000, and CE certification. To achieve this, manufacturers adopt stainless-steel construction, PLC-controlled automation, and precision sensors for temperature and pressure control. These technologies minimize human handling, reduce contamination risks, and maintain consistent quality across large production volumes.

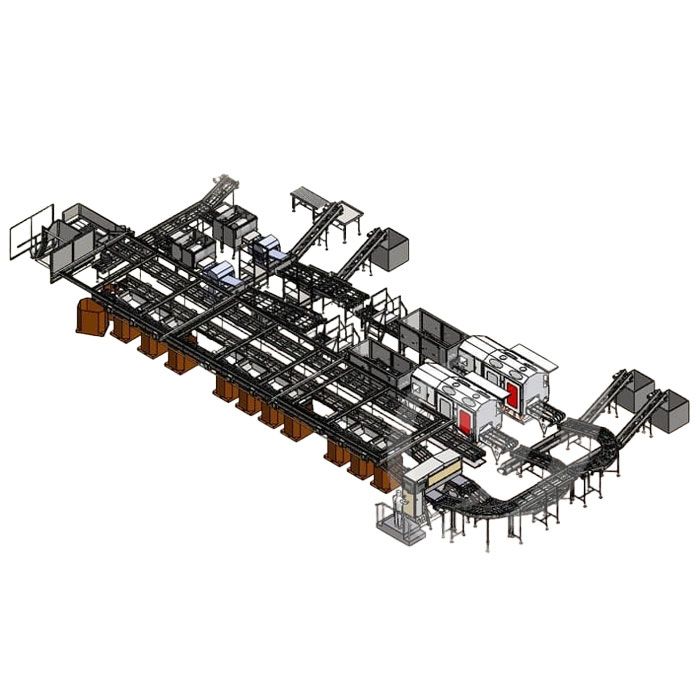

A typical poultry processing line includes automatic slaughtering systems, scalding and plucking machines, evisceration and cleaning systems, portioning and deboning equipment, freezing tunnels, and vacuum packaging units. Each component is designed to optimize throughput while ensuring gentle product handling to preserve texture and freshness. Optional modules such as grading, weighing, and labeling systems further streamline production and traceability.

Top poultry processing machinery manufacturers provide complete turnkey solutions, including factory layout design, equipment customization, installation, commissioning, and staff training. These tailored systems can be adapted for chicken, duck, turkey, or quail processing plants, whether for small-scale operations or large industrial facilities. Their engineering teams focus on energy efficiency, water recycling, and easy maintenance, helping clients reduce operational costs while meeting environmental standards.

Chinese suppliers have become increasingly competitive in the global market due to their innovative designs, cost-effective manufacturing, and strong after-sales support. Many export to Southeast Asia, Africa, the Middle East, and South America, where demand for hygienic, automated poultry processing continues to rise.

By combining technological expertise with a deep understanding of food industry requirements, these manufacturers help processors modernize their production facilities, enhance food safety, and improve overall profitability. Whether for fresh, frozen, or cooked poultry products, partnering with a reliable poultry processing equipment manufacturer ensures long-term operational success and sustainable growth.

Types of Poultry Processing Equipment & Applications

| Category | Main Equipment | Core Function | Applications |

|---|---|---|---|

| Slaughtering Systems | Stunning units, bleeding conveyors, scalding tanks | Humane slaughtering, feather-loosening preparation | Chicken, duck, turkey processing plants |

| Defeathering Machines | Automatic pluckers, rubber finger drums | Efficient removal of feathers without skin damage | Broiler and duck processing |

| Evisceration Systems | Vent cutters, gutting machines, washing tunnels | Internal organ removal and carcass cleaning | Fresh and frozen poultry lines |

| Portioning & Cutting Equipment | Meat cutters, slicers, filleting machines, bone separators | Precise segmentation into wings, breasts, thighs | Retail and ready-to-cook poultry |

| Deboning Machines | Mechanical deboners, separators | Extracting lean meat with minimal waste | Chicken nuggets, sausage, and meat paste processing |

| Chilling & Freezing Units | Air chillers, spiral freezers, IQF systems | Rapid cooling or freezing to preserve freshness | Frozen meat, export-grade poultry |

| Grading & Weighing Systems | Weighing conveyors, vision grading systems | Product classification by size or weight | Standardized packaging and distribution |

| Packaging Lines | Vacuum packers, tray sealers, labeling machines | Sealing, labeling, and coding for retail or wholesale | Frozen or marinated chicken packaging |

| By-product Processing Systems | Fat melters, feather dryers, rendering units | Processing secondary materials for reuse | Poultry oil, feed, and fertilizer production |

| Automation & Control Systems | PLC controllers, touchscreen panels, data monitoring software | Centralized process control and quality tracking |

Meat Canned Food Production Line

Meat Canned Food Production Line Braised Pork Belly Can Production Line

Braised Pork Belly Can Production Line Chicken Soup Canned Production Line

Chicken Soup Canned Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line Automatic Chicken Canned Food Production Line

Automatic Chicken Canned Food Production Line Fully Automatic Meat Can Production Lines

Fully Automatic Meat Can Production Lines Heavy Duty Commercial Meat Grinder

Heavy Duty Commercial Meat Grinder Chicken Production Line

Chicken Production Line Meat Dicers

Meat Dicers Heavy Duty Meat Slicer Machine

Heavy Duty Meat Slicer Machine YL-W-04 Commercial Water Purification Equipment

YL-W-04 Commercial Water Purification Equipment Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Food X-ray Foreign Object Detector

Food X-ray Foreign Object Detector Commercial Pasta Extruder

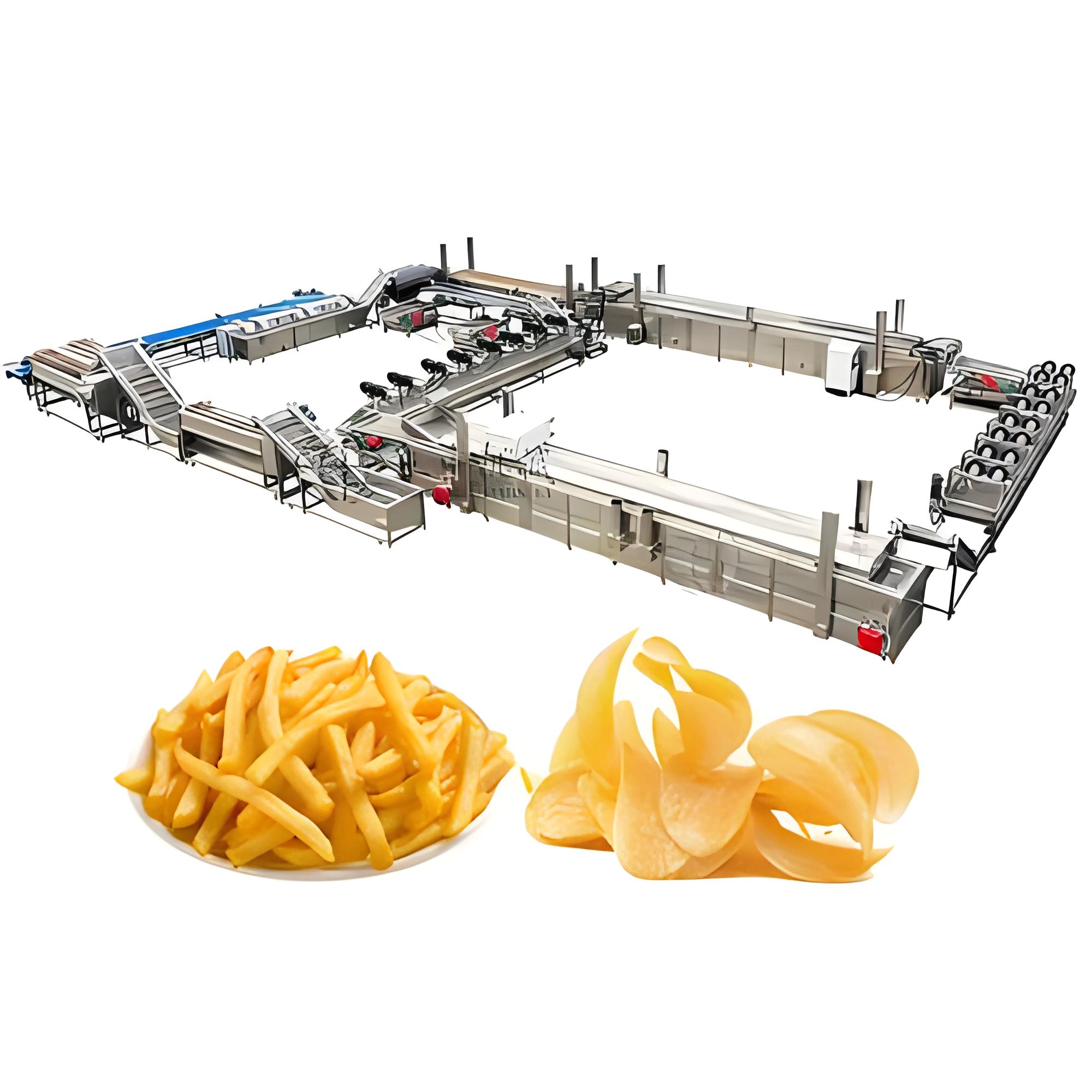

Commercial Pasta Extruder French Fries Production Line

French Fries Production Line Smoked Furnace

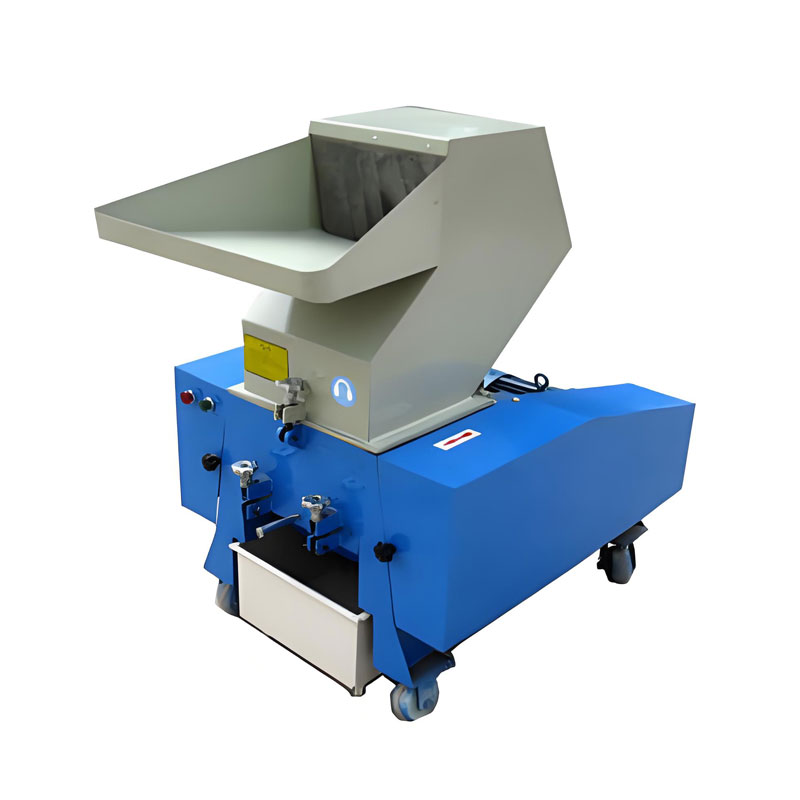

Smoked Furnace Automatic Bone Crushing Machine

Automatic Bone Crushing Machine