Sterilization Equipment For Fish Canning Production Line - Chinese Manufacturer, Factory, Supplier

Sterilization is a critical stage in any fish canning production line, ensuring food safety, extending shelf life, and preserving the quality of canned fish. Advanced sterilization equipment for fish canning production lines is specifically designed to eliminate harmful microorganisms while maintaining the natural flavor, texture, and nutritional value of seafood products such as sardines, mackerel, tuna, and salmon.

Modern sterilization units are highly automated and integrate seamlessly with upstream and downstream processes, including cleaning, cutting, cooking, filling, seaming, and labeling. They typically use high-pressure steam, water, or a combination of both to achieve uniform thermal treatment. Precise temperature control and timed cycles ensure that each can receives consistent sterilization, meeting stringent food safety standards such as HACCP, ISO, FDA, and CE regulations.

Depending on production capacity and can size, sterilization equipment can range from small batch autoclaves for regional processors to large continuous retort systems capable of handling thousands of cans per hour. These systems often feature PLC control with touchscreen interfaces, allowing operators to monitor temperature, pressure, and timing in real time. Advanced units also include automatic loading and unloading mechanisms, reducing manual labor and improving overall line efficiency.

A significant advantage of high-quality sterilization equipment is its ability to maintain product integrity while preventing spoilage. Uniform heat penetration prevents overcooking and nutrient loss, while vacuum or steam injection systems reduce oxygen inside the can, protecting fish from oxidation. Cooling systems following sterilization rapidly lower the temperature of cans, preventing thermal shock and ensuring they are ready for labeling and packaging.

Durability and hygiene are also key considerations. The equipment is generally made from corrosion-resistant, food-grade stainless steel, designed for easy cleaning and maintenance. Safety features, including pressure relief valves, interlocks, and automated alarms, ensure safe operation in high-temperature, high-pressure environments.

Leading manufacturers, such as Qingdao Hongshengyuanlin Co., Ltd., established in 2014, provide turnkey solutions that include sterilization equipment as a core part of the fish canning production line, with customized options for various can sizes, production speeds, and product types. They also provide technical support, operator training, and maintenance services to guarantee reliable, long-term operation.

Investing in advanced sterilization equipment for fish canning production lines not only enhances food safety and product shelf life but also improves operational efficiency, reduces labor costs, and ensures consistent quality for both domestic and international markets. It is an essential component for any modern seafood processing facility seeking to meet the highest standards in canned fish production.

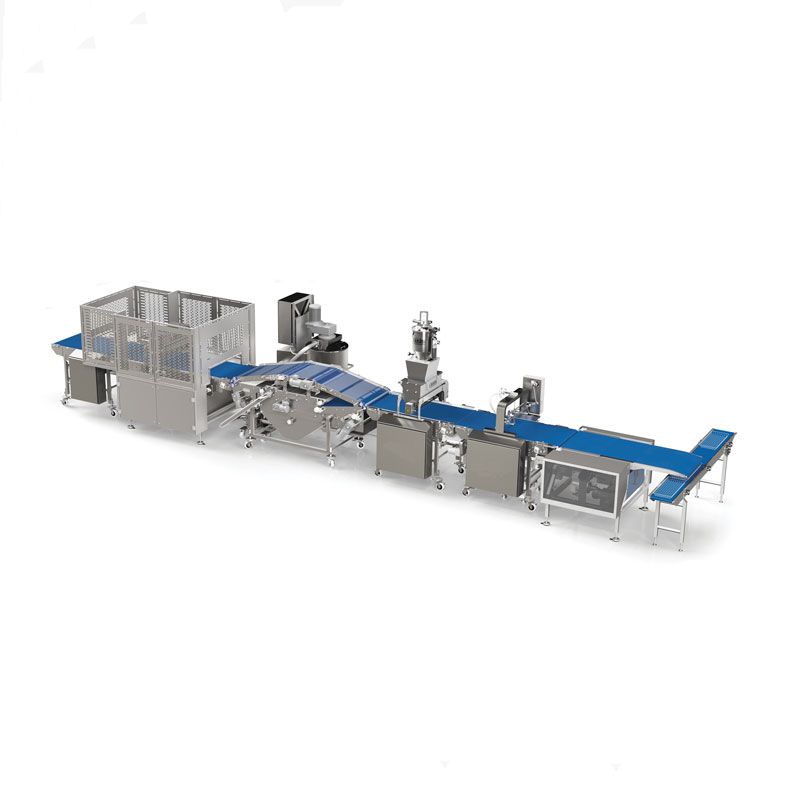

Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Eel Canned Food Production Line

Eel Canned Food Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line Donut Production Line

Donut Production Line Pizza Cone Equipment

Pizza Cone Equipment Automatic Meat Mixer Machine

Automatic Meat Mixer Machine Dough Divider Rounder

Dough Divider Rounder Dual-Roll Steamed Bun Machine

Dual-Roll Steamed Bun Machine Frozen French Fries Production Line

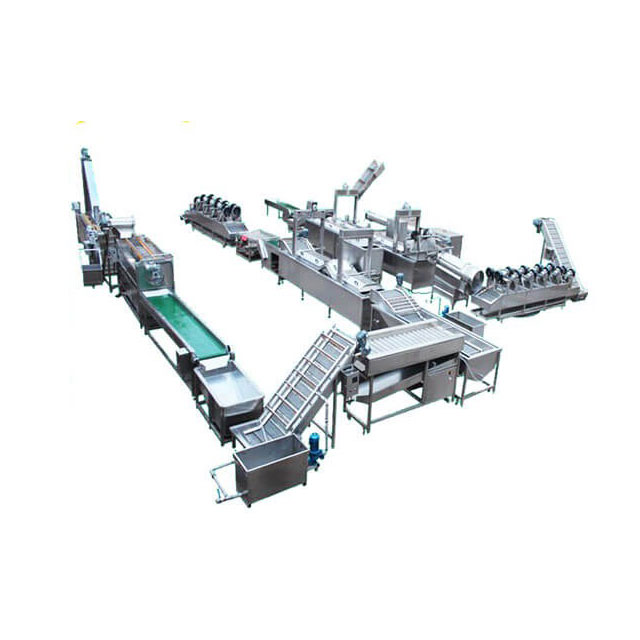

Frozen French Fries Production Line Membrane Skinner

Membrane Skinner Multifunction Pasta Machine

Multifunction Pasta Machine