Tomato Ketchup Production Line Equipment - Chinese Manufacturer, Factory, Supplier

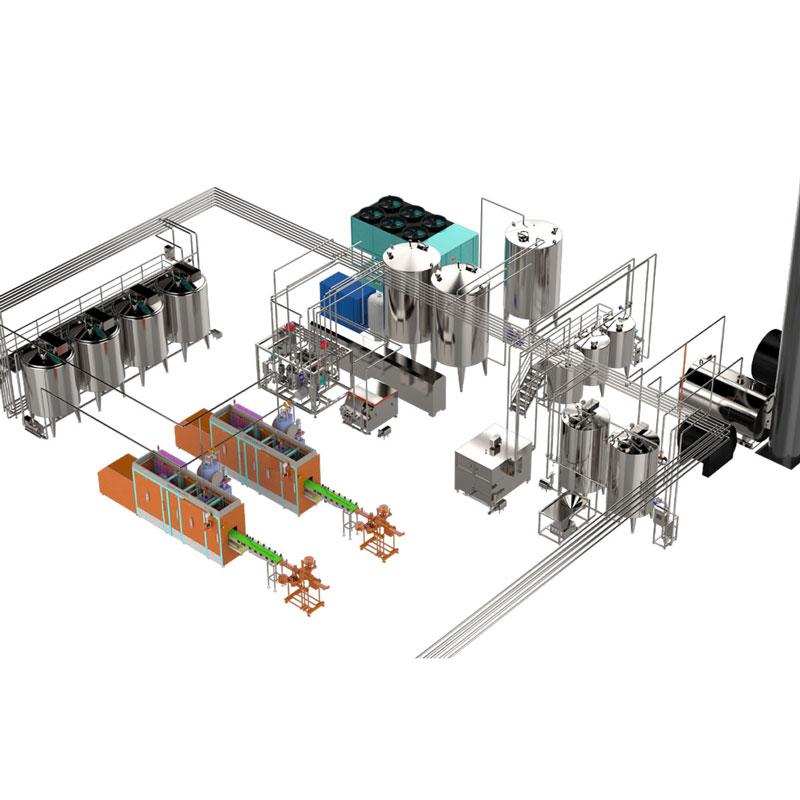

The commercial production of ketchup relies heavily on tomato ketchup production line equipment to deliver efficiency, consistency, and quality. From initial washing and peeling of raw tomatoes to crushing and pulping, this equipment ensures the preservation of nutrients while creating a smooth, homogeneous base. Advanced vacuum evaporators and heat exchangers concentrate the pulp efficiently, maintaining flavor, color, and texture while reducing energy consumption. Precision dosing units and high-performance mixers guarantee that sugar, salt, spices, and stabilizers are blended uniformly, achieving the desired taste and viscosity for downstream filling and packaging. Sterilization and pasteurization modules integrated within the tomato ketchup production line equipment ensure microbiological safety without compromising aroma or natural color. Automated filling and packaging systems deliver speed, accuracy, and reduced labor costs, while stainless steel construction, CIP (clean-in-place) capability, and smooth surfaces facilitate hygiene and contamination control. Modular design allows producers to scale production seamlessly according to market demand, enhancing flexibility and operational continuity. By combining advanced processing, precise formulation, and automated handling, tomato ketchup production line equipment not only improves productivity but also guarantees consistent quality, ensuring every bottle meets consumer expectations. For manufacturers seeking reliability, safety, and efficiency, investing in modern production line equipment is both an operational necessity and a strategic step toward establishing a trusted brand in the competitive food industry.

Small Scale Tomato Sauce Making Machine

Small Scale Tomato Sauce Making Machine Tomato Sauce Milling Machine

Tomato Sauce Milling Machine Tomato Sauce Grinding Machine

Tomato Sauce Grinding Machine Tomato Juice Processing Production Line

Tomato Juice Processing Production Line Tomato Sauce Machine

Tomato Sauce Machine Tomato Sauce Packaging Machine

Tomato Sauce Packaging Machine Tomato Ketchup Processing Line

Tomato Ketchup Processing Line Tomato Paste Production Line

Tomato Paste Production Line Smoked Furnace

Smoked Furnace Commercial Pasta Sheeter

Commercial Pasta Sheeter Biscuit Making Equipment

Biscuit Making Equipment Automatic Dumpling Making Machine

Automatic Dumpling Making Machine Yogurt Production Line

Yogurt Production Line Fish Speed Cleaning Machine

Fish Speed Cleaning Machine Sausage Processing Line

Sausage Processing Line Poultry Slaughtering Line

Poultry Slaughtering Line