Fish Canning Production Line Supplier - Chinese Manufacturer, Factory, Supplier

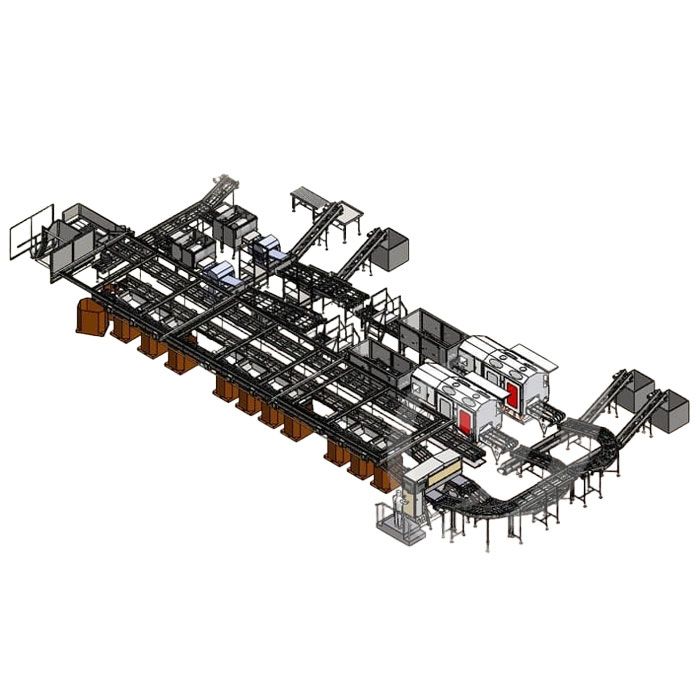

As a leading fish canning production line supplier, Qingdao Hongshengyuanlin Co., Ltd. provides turnkey solutions for seafood processing factories worldwide. Our fully automatic canning lines are designed for high efficiency, hygiene, and flexibility, covering every stage from raw material handling to final packaging.

The complete fish canning production line includes processes such as fish receiving, cleaning, cutting, cooking, filling, sealing, sterilization, cooling, and labeling. Each section is precisely engineered to maintain product integrity, ensure uniform quality, and meet international food safety standards such as HACCP, ISO, and CE.

Constructed with food-grade stainless steel, our equipment ensures durability, corrosion resistance, and easy maintenance. The automated control systems allow real-time monitoring and data recording, helping operators achieve consistent output and reduce labor costs. Production capacity can be customized according to client needs—from small-scale batch operations to large industrial canning plants.

Our fish canning solutions are suitable for sardines, mackerel, tuna, anchovies, and other seafood varieties, supporting various can sizes and packaging formats (such as 125g, 155g, 425g, or customized tin cans). Optional modules include automatic brine or oil filling systems, retort sterilizers, and labeling or packing machines to create a seamless, continuous production flow.

With extensive project experience across Asia, the Middle East, Africa, and South America, Qingdao Hongshengyuanlin offers more than just machinery—we deliver complete engineering support, including factory layout design, equipment installation, operator training, and after-sales maintenance.

By choosing Hongshengyuanlin as your fish canning production line partner, you gain a reliable supplier focused on innovation, energy efficiency, and long-term performance. Our integrated systems help clients increase productivity, ensure food safety, and enhance profitability in today’s competitive seafood market.

Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Meat Canned Food Production Line

Meat Canned Food Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Peach Canned Food Production Line

Peach Canned Food Production Line Braised Pork Belly Can Production Line

Braised Pork Belly Can Production Line Canned Fruit Production Line Equipment

Canned Fruit Production Line Equipment Edible Mushroom Canned Food Production Line

Edible Mushroom Canned Food Production Line Automatic Meatball Production Line

Automatic Meatball Production Line Quantitative Vacuum Sausage Filler

Quantitative Vacuum Sausage Filler Automatic Sardine Canning Line Equipment

Automatic Sardine Canning Line Equipment  SD-3000 / SD-4000 Commercial Cube Ice Maker

SD-3000 / SD-4000 Commercial Cube Ice Maker Tomato Ketchup Processing Line

Tomato Ketchup Processing Line Small Scale Banana Chips Production Line

Small Scale Banana Chips Production Line Carrot Processing Line

Carrot Processing Line Screw Potato Peeling Washing Machine

Screw Potato Peeling Washing Machine