Which Company Sells the Best Canned Mackerel Production Line

Introduction: Global Canned Fish Market and Automation Trends

The global canned fish market is experiencing rapid growth due to increasing demand for seafood products. Emerging markets in Southeast Asia, Africa, and the Middle East are driving demand for tuna, sardines, mackerel, and other canned fish products. At the same time, stricter food safety standards and regulations are pushing producers to adopt higher hygiene levels, better production efficiency, and consistent quality.

Manual or semi-automatic production methods are no longer sufficient. Automated canned fish production lines have become essential for companies aiming to reduce labor costs, improve productivity, and ensure consistent product quality.

For B2B buyers, however, choosing the right supplier can be challenging. Many manufacturers offer canned fish production lines, but their equipment quality, automation level, pricing, and after-sales service vary significantly. This article provides a detailed guide covering production processes, equipment configurations, selection criteria, and ROI analysis to help buyers make informed decisions.

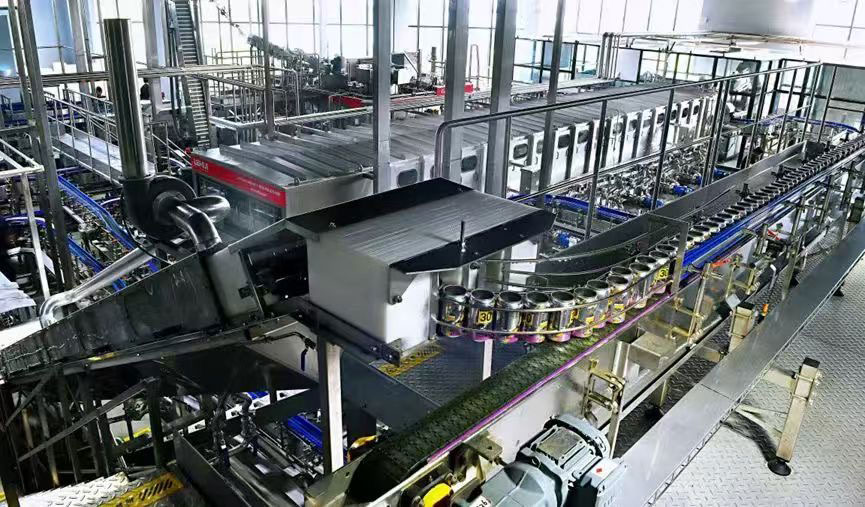

Core Components and Process Flow of a Canned Fish Production Line

A high-efficiency and reliable canned fish production line typically consists of the following core modules:

1. Raw Material Preparation

Before processing, fish must be cleaned, de-headed, de-boned, and cut into portions. Advanced lines use automated de-boning machines, scaling equipment, and high-pressure water cleaning systems to ensure hygiene, reduce labor, and maintain product quality.

2. Pre-Cooking and Cooling System

Fish is pre-cooked to remove odors, kill bacteria, and maintain texture. Modern production lines include controlled-temperature steamers and continuous cooling systems that preserve fish integrity while minimizing nutrient loss.

3. Filling and Liquid Addition

Filling is the core step of canned fish production. Liquids such as brine, vegetable oil, or tomato sauce are added based on the product type. High-end filling machines feature automatic weighing, liquid-level monitoring, and vacuum filling technology to ensure uniform weight and prevent spillage or empty cans.

4. Seaming Equipment

The sealing process directly affects product shelf life. Automatic vacuum seaming machines provide efficient and secure sealing, while removing excess air to reduce spoilage risk.

5. Sterilization and Cooling System

Sterilization is the most critical step for food safety. High-temperature, high-pressure sterilizers with PLC control ensure complete microbial elimination while maintaining fish texture. Continuous cooling systems then quickly reduce can temperature to stabilize the contents.

6. Labeling and Packaging

Automatic labeling, shrink-wrapping, and carton packing systems provide neat, standardized packaging suitable for logistics and brand presentation.

In summary, the automation level, process precision, and equipment quality of a canned fish production line directly influence production efficiency, product consistency, and overall ROI.

Key Considerations When Purchasing a Canned Fish Production Line

For B2B buyers, purchasing a production line is a long-term investment, not just a one-time equipment purchase. Key factors to consider include:

Production Capacity

Ensure the line can meet your daily output requirements and accommodate various can sizes.Hygiene and Food Safety

Equipment should be made of food-grade stainless steel (304/316) and comply with HACCP, ISO22000, CE, or other international certifications.Automation and Energy Efficiency

Automated lines reduce labor, improve efficiency, and minimize energy and material waste.Reliability and Durability

Key components should have long lifespans and low failure rates to avoid downtime.Installation, Commissioning, and Training

Check whether the manufacturer provides complete setup, operator training, and guidance for smooth startup.After-Sales Support and Spare Parts Availability

Timely support ensures long-term operational stability.Cost and Return on Investment (ROI)

Consider not only the purchase price but also labor savings, increased output, and improved product quality.

Types of Canned Fish Production Line Manufacturers

The market generally offers the following types of suppliers:

Domestic Manufacturers vs. International Brands

International Brands: Companies like Marel and Baader offer mature, high-automation solutions. However, they are expensive and may require longer maintenance cycles, suitable for companies seeking high-end, stable production.

Domestic Manufacturers: Over the past decade, Chinese manufacturers have improved automation and customization capabilities. They are cost-competitive and increasingly reliable, making them attractive for mid-sized producers and export-oriented businesses.

Technology and Process Levels

High-End Manufacturers: Full automation with weighing, precise filling, and intelligent monitoring systems. High efficiency and consistent output.

Mid-Level Manufacturers: Semi-automatic solutions with reasonable pricing, suitable for expansion or startups.

Low-End Manufacturers: Basic production capability with frequent maintenance needs and less stable output.

Choosing the Right Manufacturer for Your Needs

New Factories: Prefer manufacturers that provide turnkey solutions to reduce management complexity.

Capacity Expansion Projects: Focus on compatibility and upgrade potential to allow future expansion.

Export-Focused OEM/ODM: Consistency, certification, and equipment reliability are key to meeting international standards.

How to Identify the “Best” Canned Fish Production Line Supplier

When evaluating suppliers, buyers should consider the following:

Experience in the Industry

Look for manufacturers with extensive canned fish experience across tuna, sardines, mackerel, and other products.Proven Cases and References

Verify successful projects, especially those exported to Southeast Asia, Africa, or the Middle East.Engineering and Design Capability

Can the manufacturer provide an end-to-end solution from raw material processing to packaging?Technical Team Strength

Evaluate whether the company has mechanical, electrical, and food engineering expertise to respond quickly to issues.Service System

Assess installation, commissioning, operator training, after-sales response, and spare parts availability.Customer Feedback and Reputation

Consult third-party reviews and references to validate reliability and service quality.

By applying these criteria, buyers can identify suppliers that are technically advanced, reliable, and cost-effective.

Investment Returns and Production Line Efficiency

Purchasing a canned fish production line is a long-term investment. Automation brings measurable benefits:

Labor Cost Reduction

Automated lines can replace 30–50% of manual labor, significantly lowering operational costs.Increased Production Efficiency

High-end lines can improve output by 40–60%, shortening production cycles.Optimized Material and Energy Usage

Precise filling and process control reduce waste and energy consumption.Higher Product Consistency

Automation ensures uniform quality, reducing defective product rates.Long-Term ROI

Compared to semi-automatic lines, fully automated lines typically deliver superior three-year ROI, especially for export businesses.

A clear understanding of ROI helps businesses balance cost and capacity for maximum efficiency.

Recommended Canned Fish Production Line Suppliers

Based on technical expertise, experience, export cases, and after-sales service, domestic suppliers with turnkey capabilities—such as [Your Company Name]—stand out:

Proven Cases: Delivered turnkey projects for sardines, mackerel, and tuna in multiple countries.

Advanced Technology: CE-compliant equipment with PLC automation, weighing filling, and sterilization monitoring.

Comprehensive Service: Installation, training, spare parts, and long-term maintenance support.

Competitive Pricing: Lower investment cost than international brands without compromising automation or stability.

Selecting a professional, full-service supplier ensures efficient production, lower operational risk, and long-term investment benefits.

Conclusion: Choosing the Right Partner

Investing in a canned fish production line is a strategic decision affecting production efficiency, cost, and product quality for years to come. Buyers should focus on:

Professional Expertise: Experience and proven track record in the canned fish industry.

Reliability: Stable equipment, mature technology, and prompt after-sales service.

Turnkey Solutions: End-to-end capability from raw material handling to packaging.

Long-Term ROI: Evaluate labor savings, production capacity, and product consistency, not just equipment price.

By evaluating suppliers based on technical strength, service quality, and customer reputation, businesses can choose a reliable partner for sustainable growth and global market competitiveness.

Must-Read Blogs For Chain Restaurants Owner

Cold Chain Rice Production Line

Cold Chain Rice Production Line Unmanned Intelligent Rice Production Line

Unmanned Intelligent Rice Production Line Automatic Rice Production Line

Automatic Rice Production Line

Ready to Get Started?