Fish Canning Production Line Equipment Manufacturer - Chinese Manufacturer, Factory, Supplier

A fish canning production line equipment manufacturer provides complete and advanced solutions for the seafood processing sector, enabling companies to streamline operations from raw fish handling to final packaging. The production line generally integrates multiple stages, including cleaning, cutting, cooking, sterilization, precise filling, double seaming, labeling, and packaging. By adopting automation, manufacturers ensure that each process is carried out with efficiency and uniformity, minimizing manual intervention while safeguarding product hygiene.

These equipment systems are engineered to accommodate different fish species such as sardines, mackerel, tuna, or salmon, and are flexible enough to meet diverse can specifications ranging from 125g to 500g or larger. The machinery complies with international standards like HACCP, ISO, and CE, ensuring that every canned product meets strict food safety requirements while extending shelf life.

For seafood processors, choosing the right equipment partner means achieving higher output, consistent quality, and reduced operational costs. Leading fish canning production line equipment manufacturers often provide turnkey services, including design, customization, installation, operator training, and technical support, which allows processors to focus on market growth rather than production bottlenecks.

By investing in professional canning solutions, businesses can expand their product portfolio, enhance competitiveness in both local and global markets, and deliver reliable canned fish products that appeal to consumers worldwide.

Aseptic Canning Production Line Equipment

Aseptic Canning Production Line Equipment Sweet Corn Canning Production Line

Sweet Corn Canning Production Line Egg Canning Production Line

Egg Canning Production Line Button Mushroom Canning Production Line

Button Mushroom Canning Production Line Apple Canning Production Line

Apple Canning Production Line Corn Canning Production Line

Corn Canning Production Line Green Bean Canned Food Production Line

Green Bean Canned Food Production Line Canned Meat Production Line

Canned Meat Production Line Canned Luncheon Meat Production Line

Canned Luncheon Meat Production Line Eel Canned Food Production Line

Eel Canned Food Production Line Pet Fish Meat Canning Production Line

Pet Fish Meat Canning Production Line Tomato Paste Production Line

Tomato Paste Production Line Unmanned Intelligent Rice Production Line

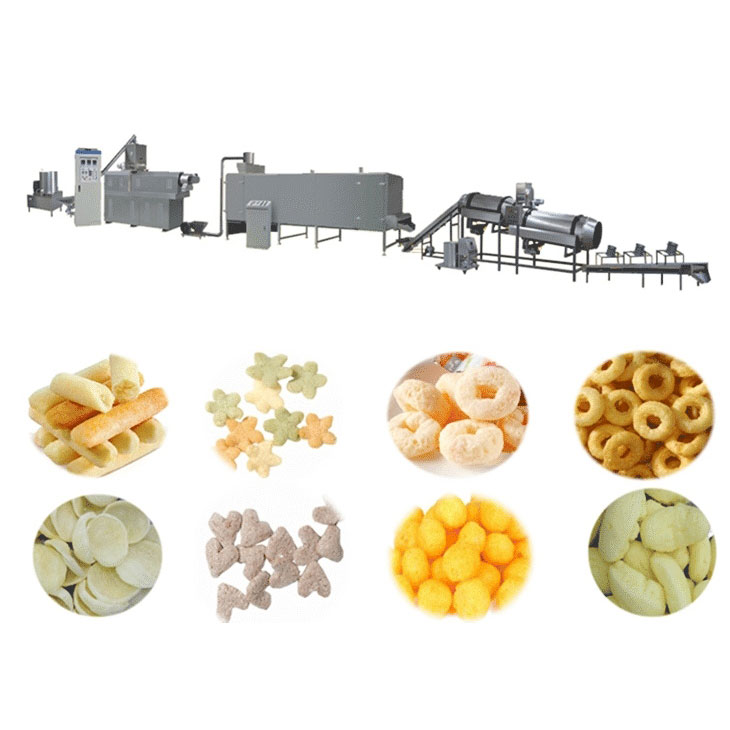

Unmanned Intelligent Rice Production Line Snack Production Line

Snack Production Line Automatic Meatball Making Machine

Automatic Meatball Making Machine Tomato Juice Processing Production Line

Tomato Juice Processing Production Line Patty Maker Machine

Patty Maker Machine SD Square Ice Series Upright Ice Makers

SD Square Ice Series Upright Ice Makers Automatic Banana Chips Production Line

Automatic Banana Chips Production Line